Cable connection device and method for circuit board ionic migration test

A cable connection and ion migration technology, applied to the casing of the measuring device, etc., can solve the problems of accelerated test cable consumption, insufficient consumption, inconvenient cleaning operation, etc., to eliminate the possibility of pollution, improve the utilization rate, and achieve good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

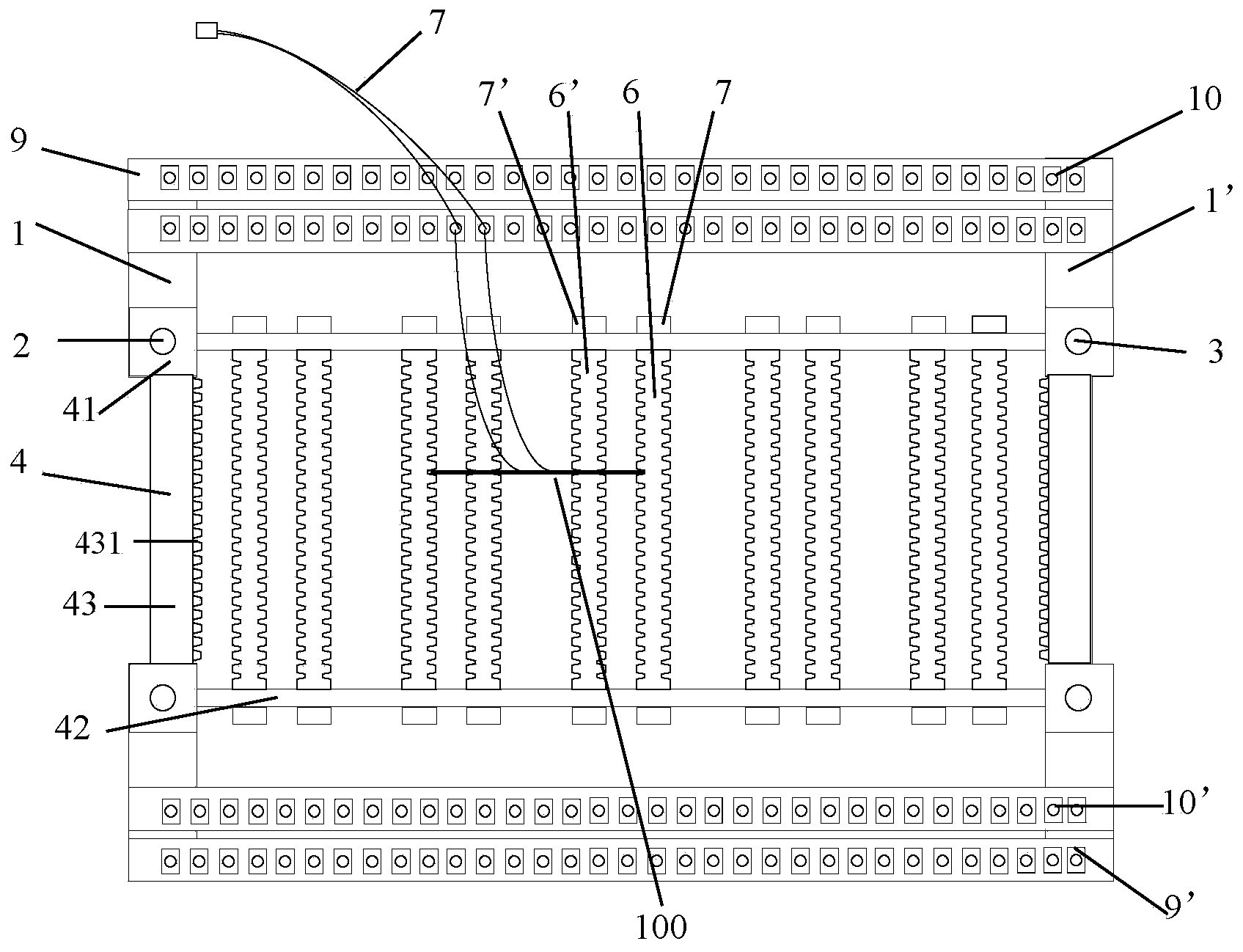

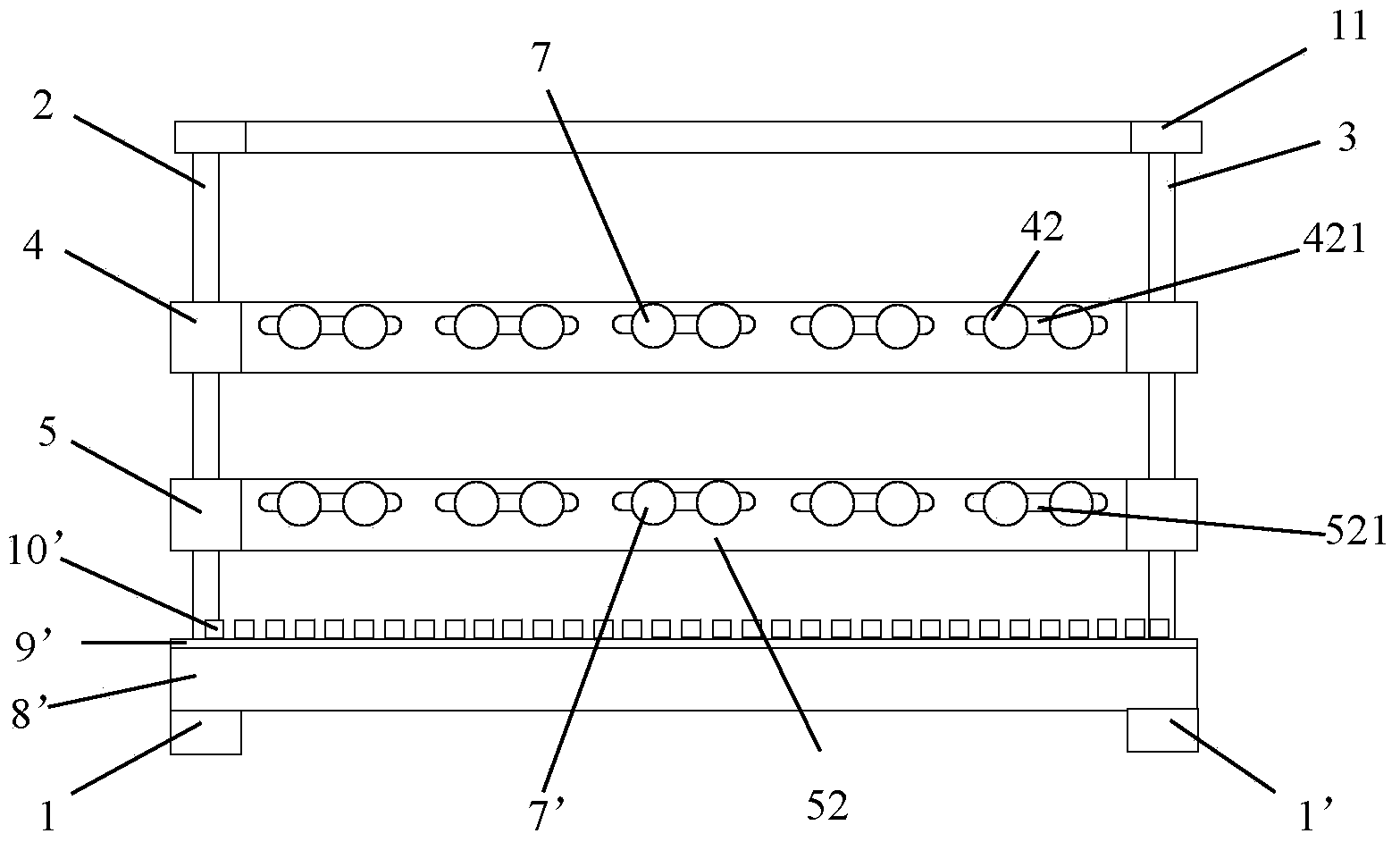

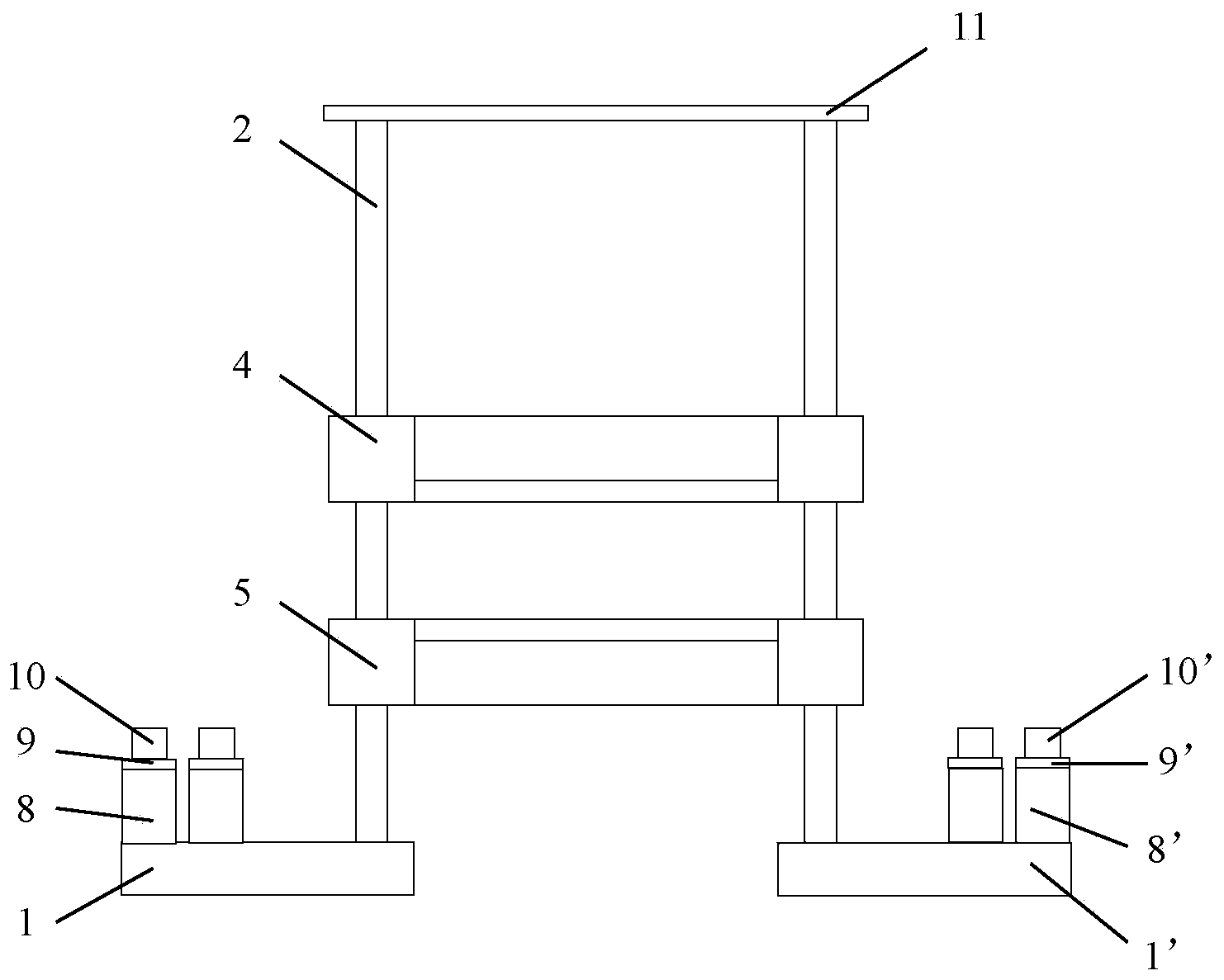

[0038] see Figure 1 ~ Figure 4, the cable connection device of the circuit board ion migration test of the present invention, it comprises, two fixed bottom plates 1,1 ', opposite arrangement; The two are arranged on the upper end surfaces of the opposite sides of the two fixed base plates 1, 1'; the upper and lower frames 4, 5 are rectangular frame structures, and their four corners are provided with the four columns 2, The column fixing blocks 41, 51 on the 3; the two long frame bars 42, 52 of the upper and lower frames 4, 5 (taking the long frame bars 42, 52 as an example, the same below) provide several guide grooves 421, 521 along the length direction A number of racks 6, 6', the two ends of which are respectively inserted into the guide grooves 421, 521 of the two long frame bars 42, 52 of the upper and lower frames 4, 5, and are locked by the fixing nuts 7, 7'; the upper and lower frames 4, 5 wide frame bar 43 (taking wide frame bar 43 as an example, the same below) h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com