Work circuit achieving stable parallel connection of multiple hollow cathodes and work method of work circuit

A hollow cathode and working circuit technology, which is applied to circuits, discharge tubes, electrical components, etc., can solve the problems of uneven current, difficult ignition, hollow cathode extinguishing, etc., and achieve the effect of reducing the potential drop of the cathode and suppressing the oscillation of the cathode discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

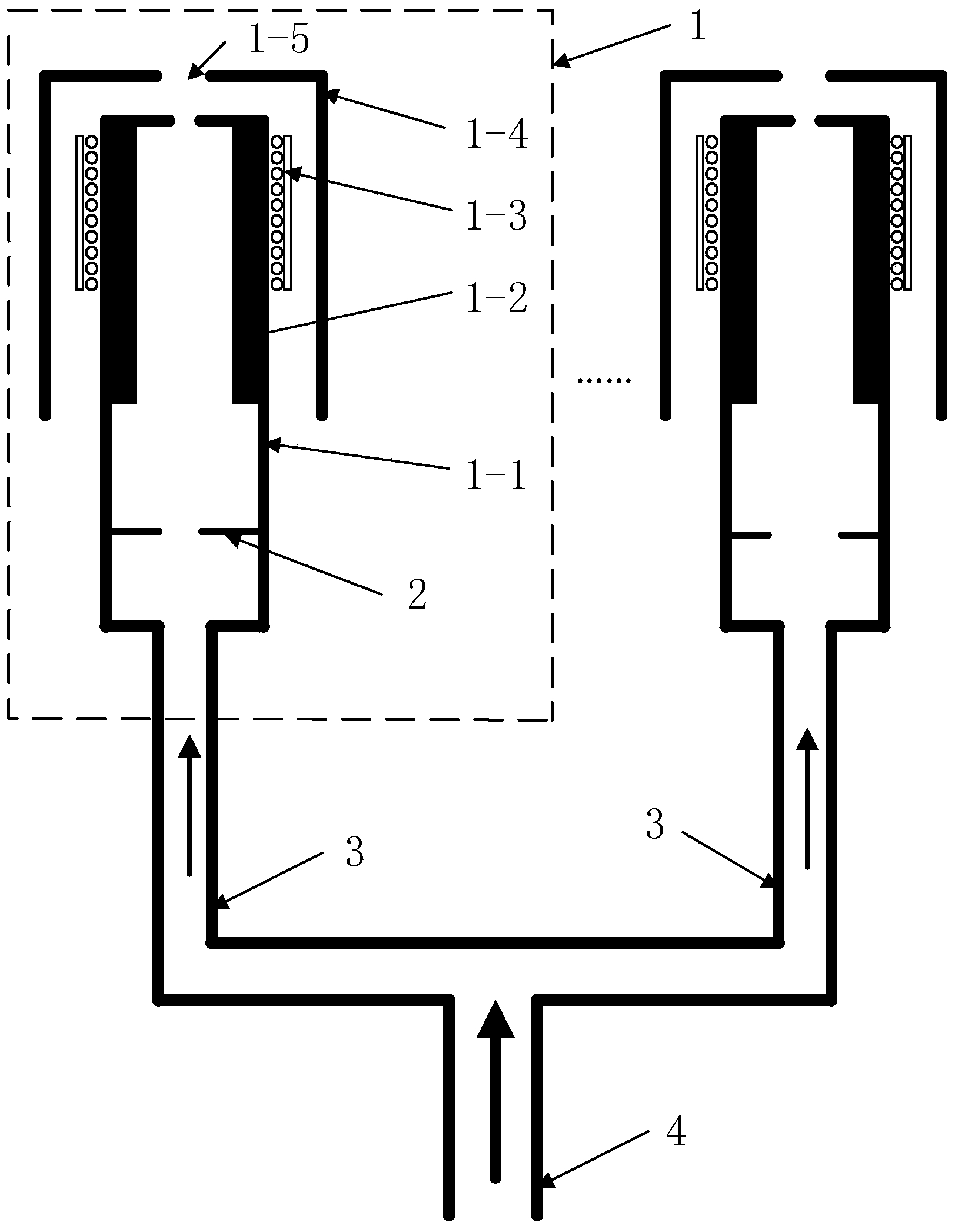

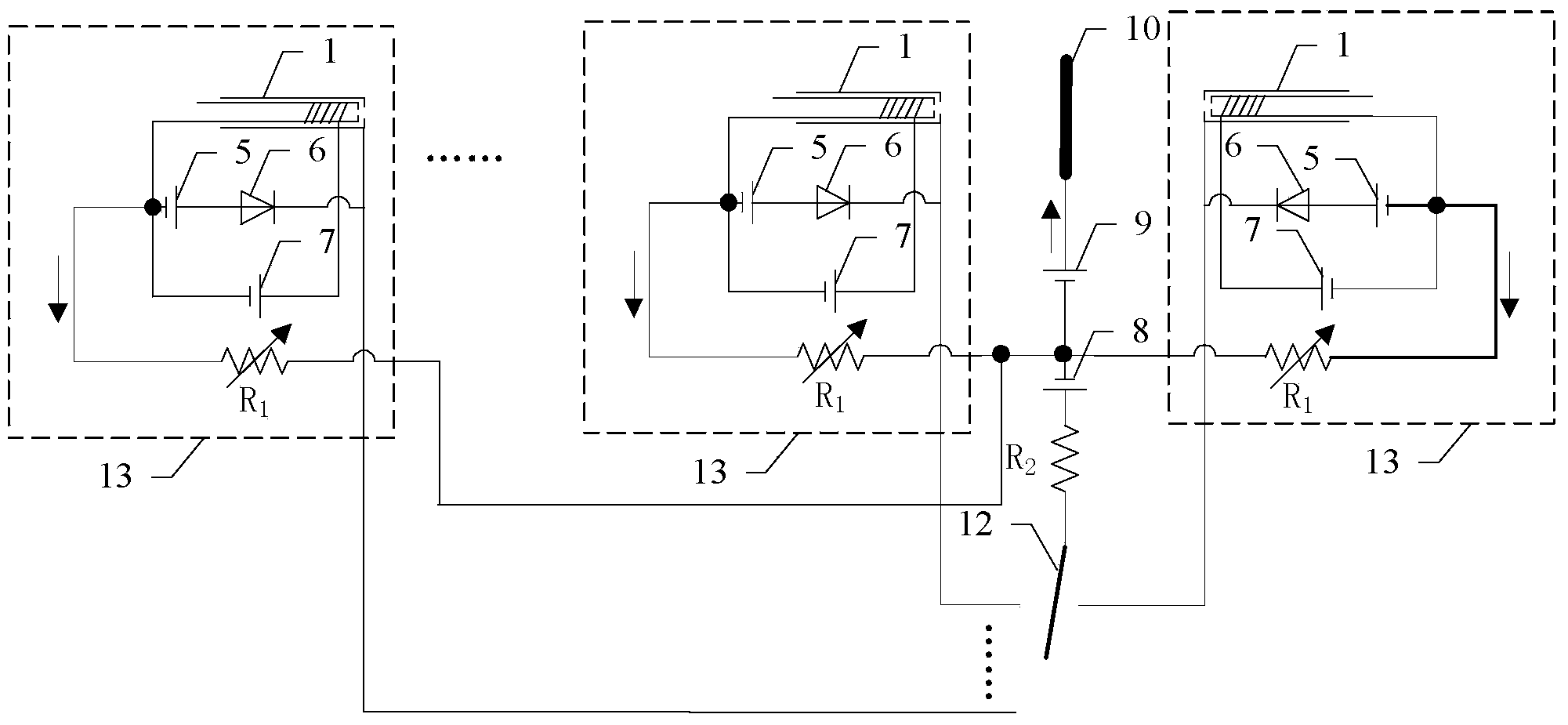

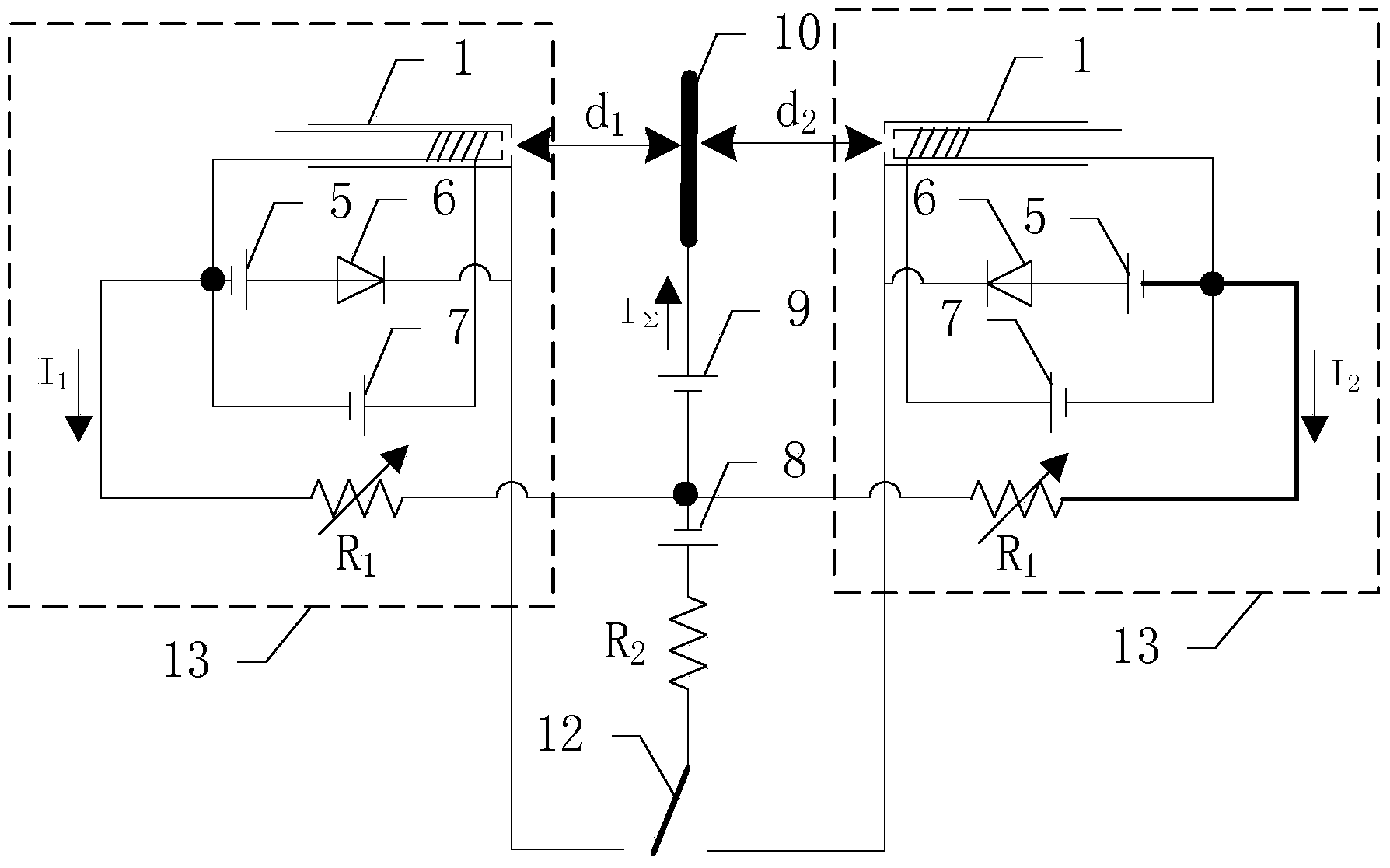

[0030] Specific implementation mode one: see figure 1 with 2 Describe this embodiment, a working circuit for realizing stable parallel connection of multiple hollow cathodes described in this embodiment, which includes a main air supply pipe 4, N branch air supply pipelines 3, a single-pole multi-throw switch 12, and a resistor R 2 , an ignition power supply 8, an anode power supply 9 and N units 13; said N is an integer greater than or equal to 2,

[0031] The first output terminals of the N units 13 are connected to the negative pole of the ignition power supply 8 and the negative pole of the anode power supply 9 at the same time, and the positive pole of the ignition power supply 8 is connected to the resistance R 2 One end of the connection, the positive pole of the anode power supply 9 is connected to one end of the anode 10,

[0032] The second output terminals of the N units 13 are respectively connected to N static ends of the single-pole multi-throw switch 12; the ...

specific Embodiment approach 2

[0043] Specific Embodiment 2: The difference between the operating circuit for realizing the stable parallel connection of multiple hollow cathodes described in the specific embodiment 1 of this embodiment is that the range of N is 2 to 20.

specific Embodiment approach 3

[0044] Embodiment 3: Based on Embodiment 1 or Embodiment 2, a working circuit that realizes stable parallel connection of multiple hollow cathodes realizes a working method for stable parallel connection of multiple hollow cathodes. The specific process of the method is as follows:

[0045] Step 1. The plume openings 1-5 of the N hollow cathodes 1 are arranged opposite to the anode 10, and the distance between the plume openings 1-5 of the hollow cathode 1 and the anode 10 is d millimeters, and the value of d is is a real number greater than 5,

[0046] Step 2, passing xenon gas into the main gas supply pipe 4;

[0047] Step 3: Connect the contact and holding pole power supply 5, the heating power supply 7 and the ignition power supply 8, connect the moving end of the single-pole multi-throw switch 12 to its N static ends in turn, and connect the holding poles 1-4 of the hollow cathode 1 to the cathode tube 1 The xenon gas between -1 is ionized, so that the hollow cathode 1 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com