Device for continuously washing and recycling foundry waste sand

A water washing device and a technology for foundry waste sand, which are applied in foundry molding equipment, manufacturing tools, machinery for cleaning/processing of mold materials, etc. problems such as large structural investment, to achieve the effect of simple structure, low cost and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

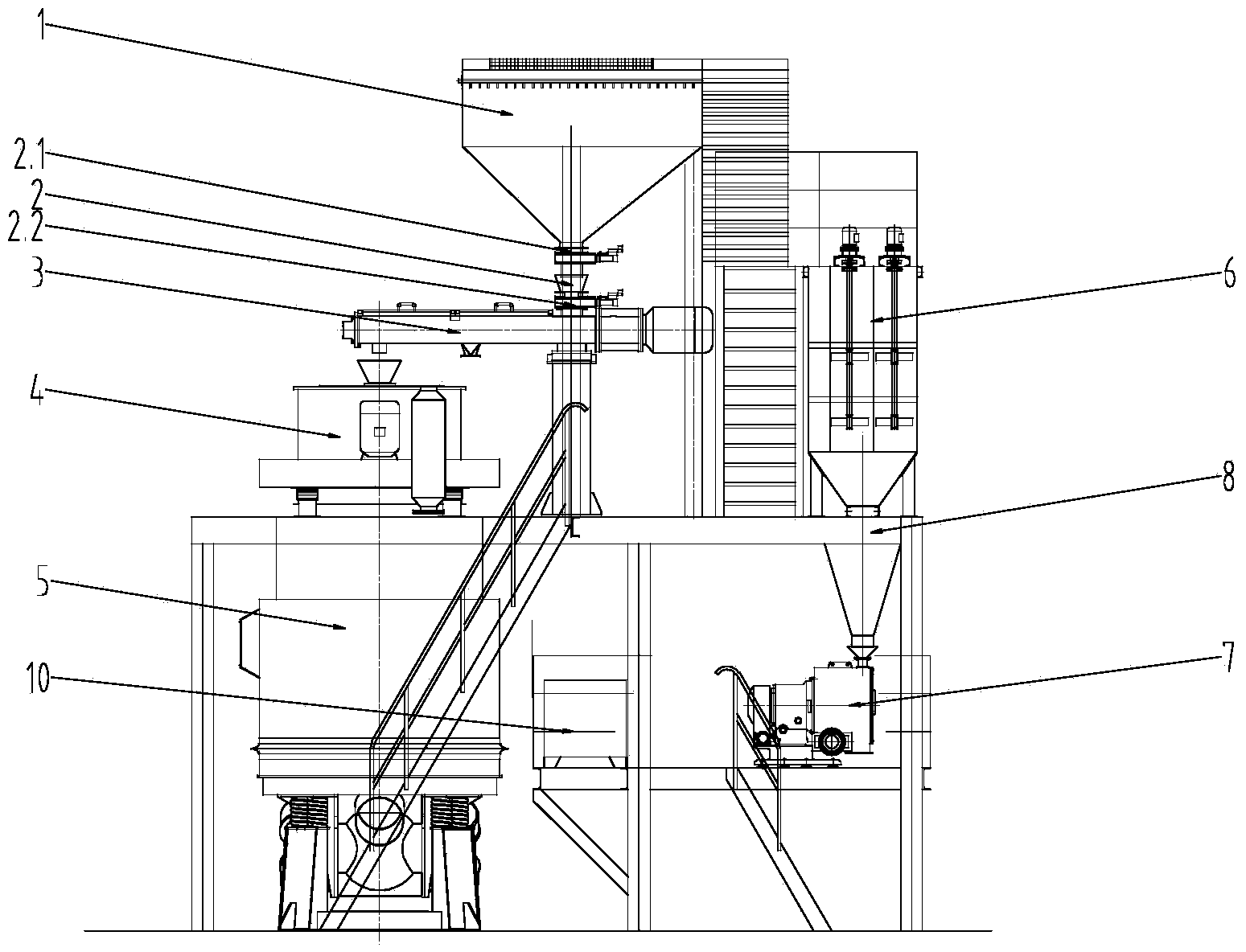

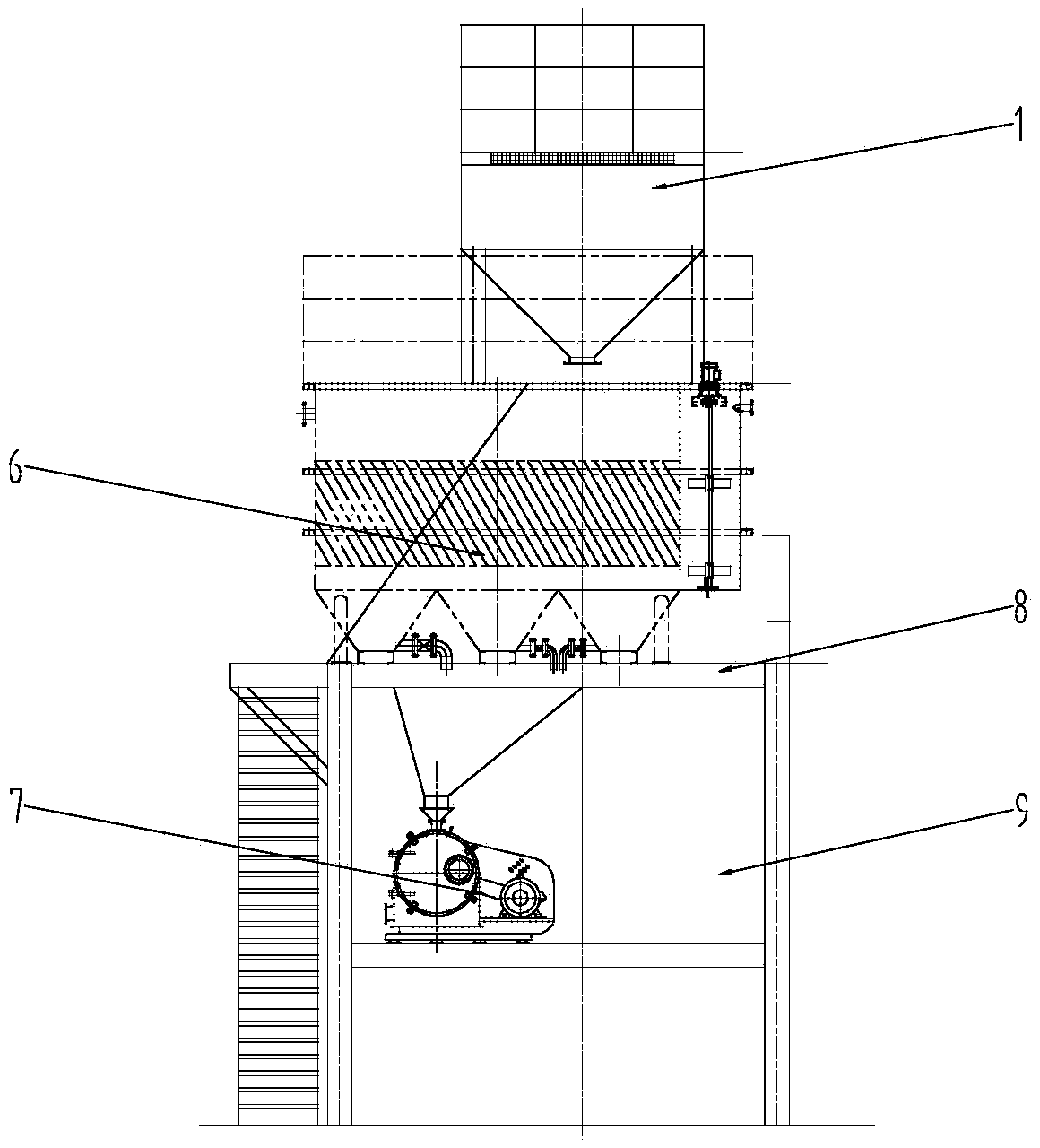

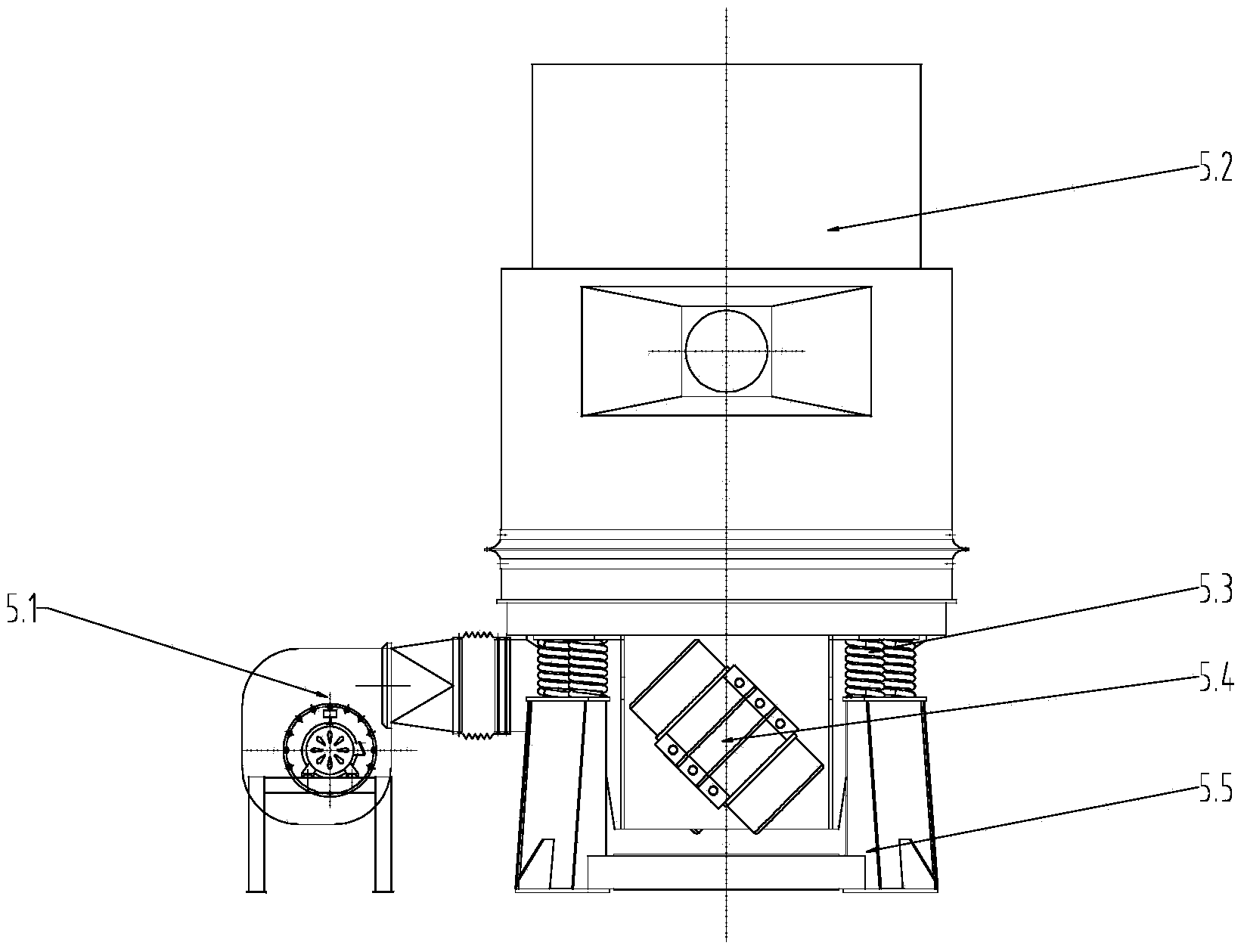

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0019] like Figure 1~2 As shown, the present invention mainly includes a soaking bucket 1, a sand bucket measuring device 2, a continuous high-speed washing device 3, a centrifugal dehydrator 4, an evaporator 5, a flotation machine 6, a continuous sludge discharge machine 7 and a support platform 8, The continuous high-speed water washing device 3 and the flotation machine 6 are fixed on the upper part of the support platform 8, the continuous high-speed water washing device 3 and the flotation machine 6 are connected through an outlet pipe, and the upper end of the continuous high-speed water washing device 3 is connected to the soaking bucket 1.

[0020] The joint of the continuous high-speed water washing device 3 and the soaking bucket 1 is provided with a sand water bucket measuring device 2, and the sand water bucket measuring device 2 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com