Mud separation equipment

A mud separation and equipment technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of large floor area of the mixing tank, high transportation cost, difficult sedimentation and stratification, etc., and achieve safe and environmentally friendly use and high work efficiency High, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

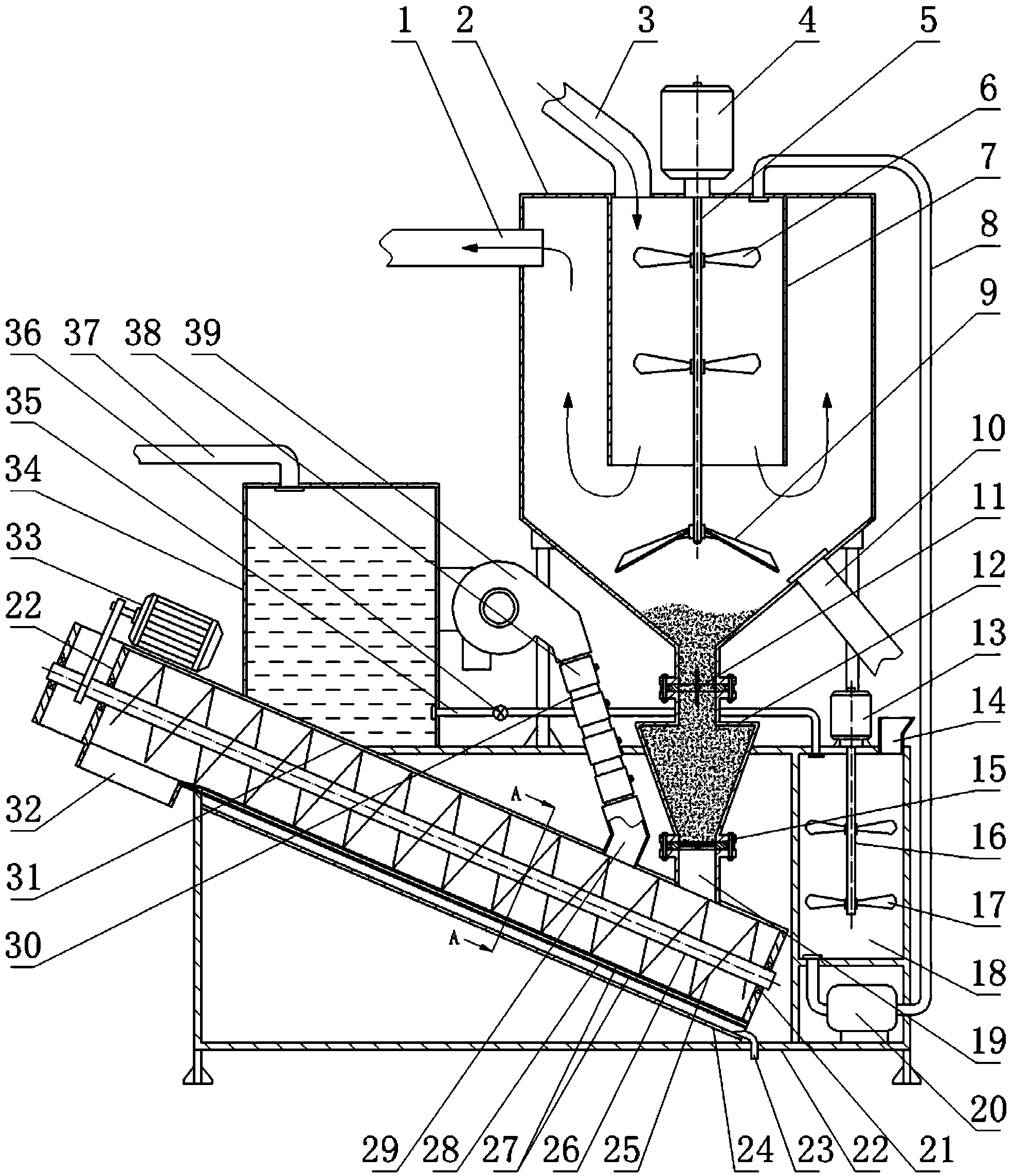

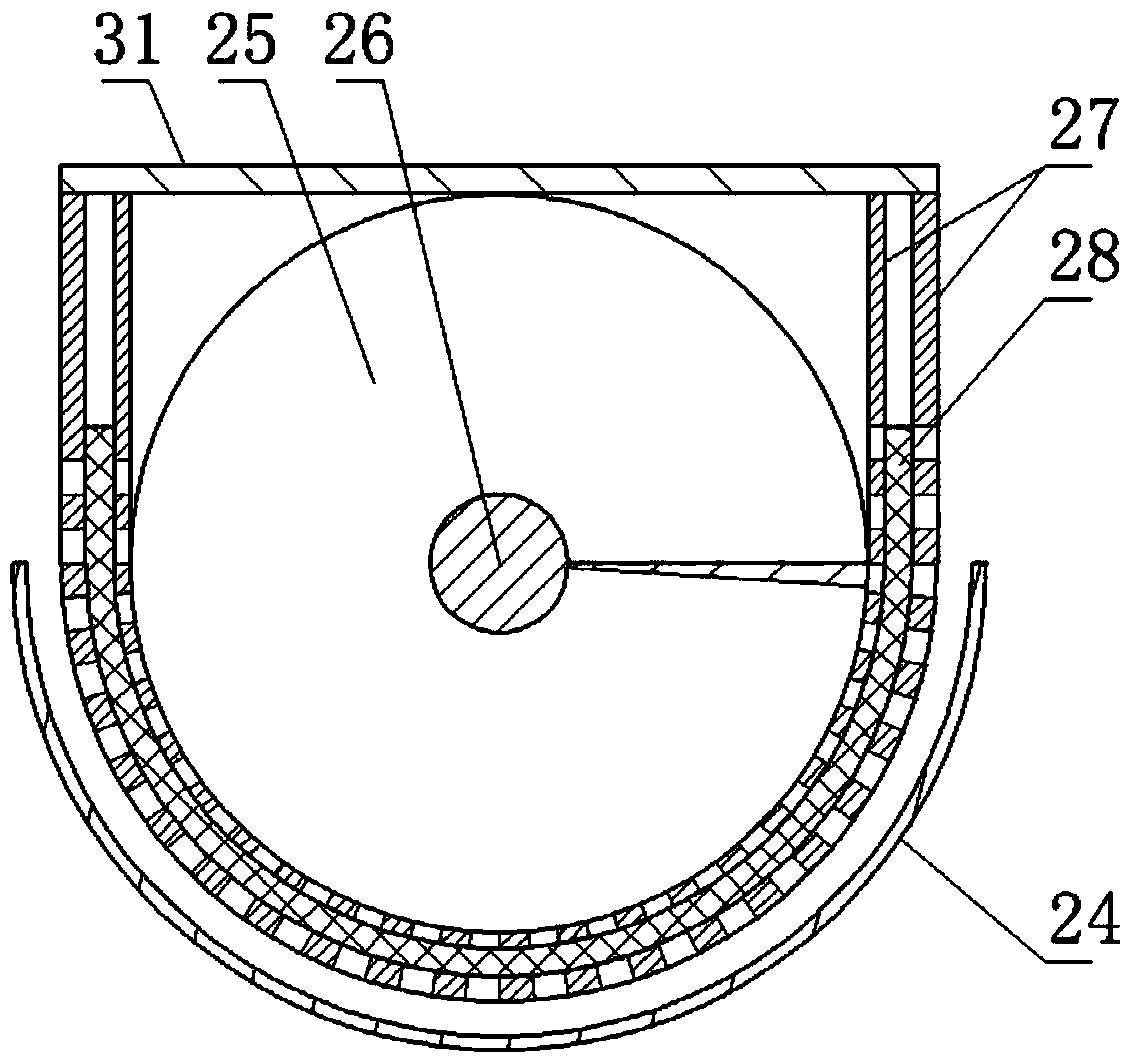

[0010] Slurry separation equipment, a separation device, a conveying and drying device and a drug supply device are housed on the frame 22, and the separation device has a stirring tank 2 and a slurry storage bucket 12, and the tank top of the stirring tank is provided with a slurry inlet pipe 3, a slurry supply Medicine tube 8 and stirring motor 4. In the stirring tank, multiple sets of stirring blades 6 are installed on the shaft connected to the stirring motor shaft 5. The stirring blades at the lower part are also called pressing blades 9. The blades can cut and lift the water flow and offset the The downward flow from the top makes the water flow at the bottom of the mixing tank tend to be stable, which is conducive to the sedimentation of the sludge, and forms a certain suction force under the blades, so that the sludge deposited from the four walls of the mixing tank is concentrated on the conical bottom of the mixing tank. At the slurry outlet; the upper stirring blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com