Method for stimulating early hydration activity of steel slag for cement production

A steel slag and cement technology, applied in clinker production, cement production and other directions, can solve the problems of increasing energy consumption, high dehydration temperature, reducing the fluidity of cement slurry, etc. The effect of chemical strength

Active Publication Date: 2016-01-20

JIANGSU BUILDING MATERIALS RES & DESIGN INST CO LTD +2

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although steel slag is also included in the composition of the ingredients, the purpose of using steel slag is to provide the calcium needed in the ingredients, and it is hoped that the required calcium can be easily released from the steel slag, so the steel slag must be selectively used. For example, in "How to Use Iron Sludge and Sludge", choose the steel slag that has been recovered from the iron after grinding with water; during the aging and maintenance process, try to make all the ingredients, including steel slag, into hydration products, and the amount of steel slag must be less than 50%. ; It will also inevitably produce two disadvantages, one is the high dehydration temperature, the maximum temperature will reach 900C 0 The second is that the water consumption of grinding into cementitious materials is high, which will cause more disadvantages due to these disadvantages, such as increasing energy consumption and reducing the fluidity of cement paste, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

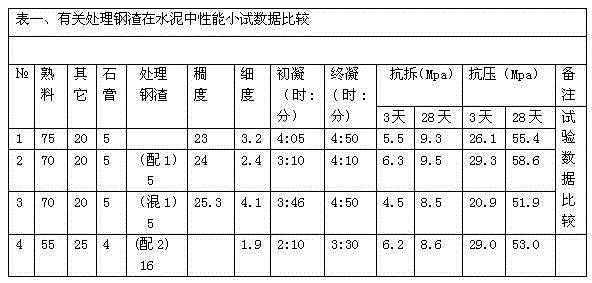

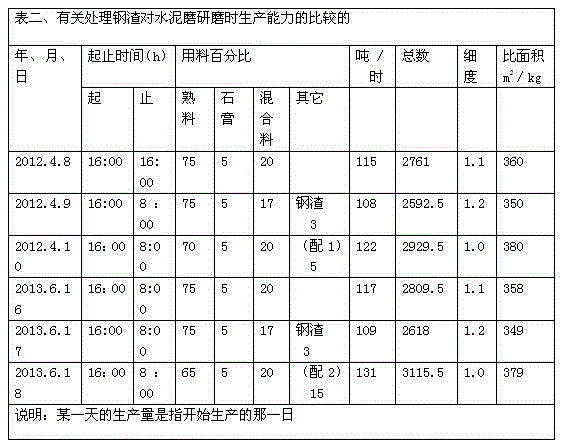

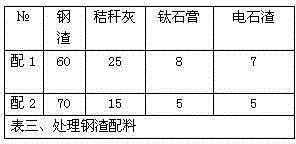

[0028] For the comparison of relevant data, see the proportion of materials in Table 1, Table 2 and Table 3. The percentages in the table refer to percentages by weight.

[0029]

[0030]

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for stimulating early hydration activity of cement steel slags. The method comprises the following steps: (1) selection and batching of raw materials; (2) stirring and mixing under a wet condition; (3) formation; (4) maintenance; and (5) dehydration. The method has the advantages that (1) the raw materials are all local industrial waste residues; (2) the amount of used steel slags in the batching is above 55%, and the batching of other materials satisfies a condition that the pH value of a slurry body during an early stirring stage is larger than 10, so formation of hydrated minerals can be promoted and the corrosion to steel slags can be enhanced; (3) the hydration period at normal temperature is 2-5 weeks; and (4) chemical refining is combined with mechanical grinding, the steel slags, straw ash, carbide slags and titanium gypsum are mixed and formed together in a wet environment and then dehydrated after two or more weeks, wherein the mixture-dehydrated and treated steel slags can be used for producing cement, are easy to grind, have the function of assisting grinding, are high in hydration speed, can be used for stimulating the hydration of cement clinkers and other materials used in the cement and increasing the hydration intensity of the cement, are environmentally friendly and low in cost.

Description

technical field [0001] The invention relates to a method for stimulating the early hydration activity of steel slag used for cement production, which belongs to the technical field of application in the field of building materials for the combined action of material corrosion and mechanical grinding to refine steel slag and stimulate the hydration activity of steel slag. . Background technique [0002] In the field of building materials, people's attention to the method of material refinement is only focused on the aspect of mechanical refinement. But for steel slag, which is too hard and difficult to grind, it is almost impossible to grind it to a certain fineness purely by machinery. Therefore, in grinding cement, steel slag is often avoided, no! In fact, chemical action has great power to corrode and destroy material particles. Although the binding energy between ions inside steel slag particles is very high, it is not easy to be destroyed. But once in contact with th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B5/00C04B7/38

CPCY02P40/121

Inventor 蒋兆广张会明蒋兆跃华建军谭纪林蒋少奎李海豹陈明吴光炜

Owner JIANGSU BUILDING MATERIALS RES & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com