High-molecular slag grinding aid, and preparation method and application thereof

A polymer and grinding aid technology, which is applied in the field of cement manufacturing, can solve problems such as complex components, unstable grinding aid effect, and general effect of small molecule compound grinding aids, so as to improve the activity index, slag activity index, and The effect of grinding aid efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

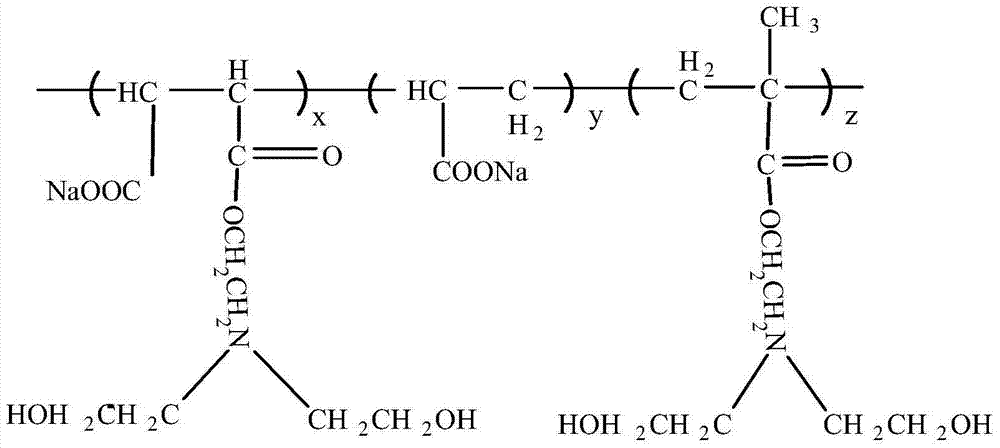

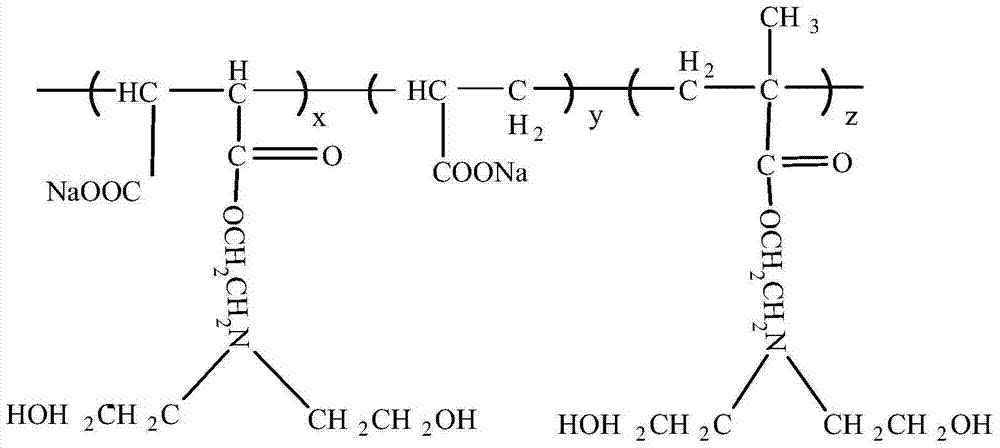

Method used

Image

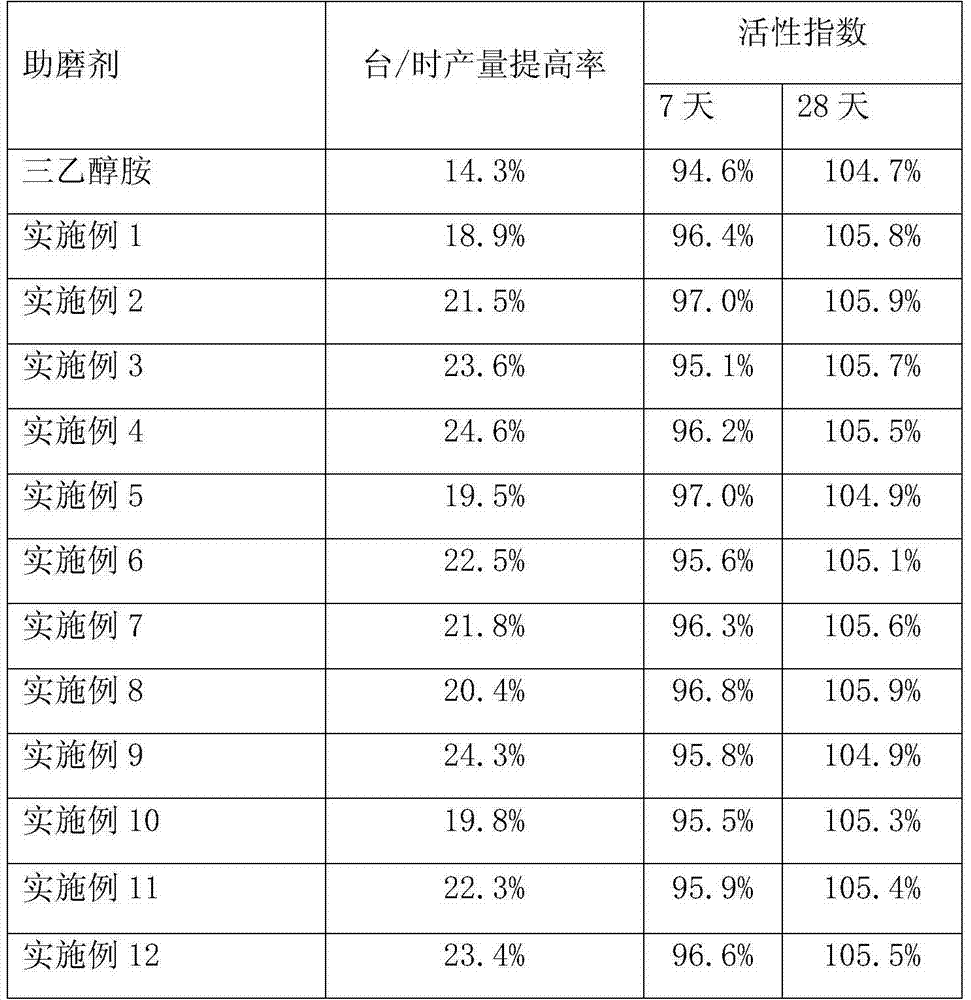

Examples

Embodiment 1

[0024] (1) Put 149.0 g of triethanolamine and 1.5 g of p-toluenesulfonic acid into a three-necked flask, then add 107.8 g of maleic anhydride, keep it at 110°C and reflux for 3 hours to prepare triethanolamine maleate (GA).

[0025] (2) Put 94.6 grams of methacrylic acid, 0.9 grams of phosphorous acid, and 0.02 grams of hydroquinone into a four-necked flask, heat to 120oC and slowly add 149.0 grams of triethanolamine dropwise, and react under reflux for 3 hours to obtain methacrylic acid Triethanolamine ester (GZ).

[0026] (3) Add 247.0 grams of GA, 65.1 grams of GZ, 28.8 grams of acrylic acid, and 247.0 grams of water into a three-necked flask. After the temperature is raised to 70oC, 49.4 grams of ammonium persulfate aqueous solution (concentration 10.0%) is uniformly added dropwise. The addition time is 2 hours. After the addition is completed, keep it at 75°C for 2.5 hours, then lower the temperature to 45°C, add NaOH to neutralize and adjust the pH of the system to about 7-8....

Embodiment 2

[0028] (1) Put 149.0 g of triethanolamine and 1.5 g of p-toluenesulfonic acid into a three-necked flask, then add 117.6 g of maleic anhydride, keep the temperature at 110°C and reflux for 3 hours to prepare triethanolamine maleate.

[0029] (2) Put 103.2 grams of methacrylic acid, 1.0 grams of phosphorous acid, and 0.02 grams of hydroquinone into a four-necked flask. The temperature is raised to 120°C and 149.0 grams of triethanolamine are slowly added dropwise. After refluxing for 4 hours, methacrylic acid is obtained. Triethanolamine ester.

[0030] (3) Add 247.0 grams of GA, 65.1 grams of GZ, 28.8 grams of acrylic acid, and 259.0 grams of water into a three-necked flask. After the temperature is raised to 70oC, 49.4 grams of ammonium persulfate aqueous solution (concentration 10.0%) are uniformly added dropwise for 2 hours. After the addition, keep it at 75oC for 3 hours, then lower the temperature to 45℃, add NaOH to neutralize and adjust the pH of the system to about 7-8.

Embodiment 3

[0032] (1) Put 149.0 grams of triethanolamine and 1.5 grams of p-toluenesulfonic acid into a three-necked flask, then add 107.8 grams of maleic anhydride, keep the temperature at 110°C and reflux for 3 hours to prepare triethanolamine maleate.

[0033] (2) Put 94.6 grams of methacrylic acid, 0.9 grams of phosphorous acid, and 0.02 grams of hydroquinone into a four-necked flask, heat to 120°C and slowly add 149.0 grams of triethanolamine dropwise, and react under reflux for 2 hours to obtain methacrylic acid Triethanolamine ester.

[0034] (3) Add 247.0 grams of GA, 65.1 grams of GZ, 57.6 grams of acrylic acid, and 255.0 grams of water into a three-necked flask. After heating to 60oC, add 50.0 grams of ammonium persulfate aqueous solution (concentration 10.0%) uniformly, and the dripping time is 1.5 hours. After the addition is completed, keep it at 70oC for 4 hours, then lower the temperature to 45°C, add NaOH to neutralize and adjust the pH of the system to about 7-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com