Post-grouting pressure type anchor rod and construction method thereof

A pressure type, anchor rod technology, applied in the engineering field, can solve the problems of high total price, difficult to guarantee construction quality, complicated grouting process and tension locking process, etc., so as to improve the compressive strength, reduce the construction cost and shorten the anchorage Effect of rod length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

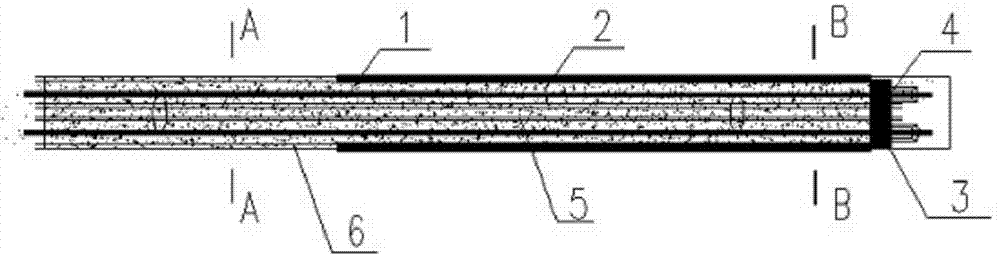

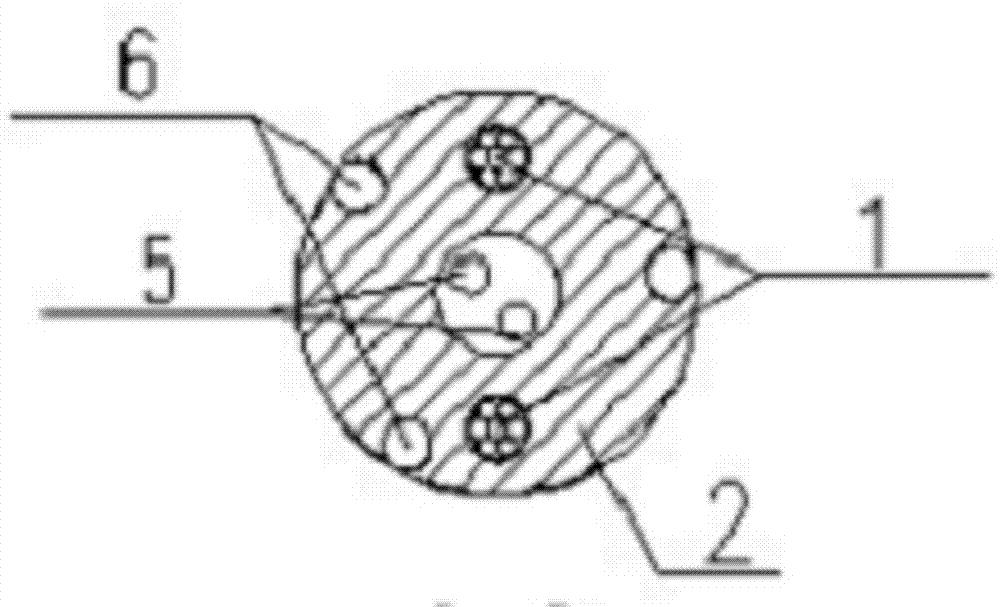

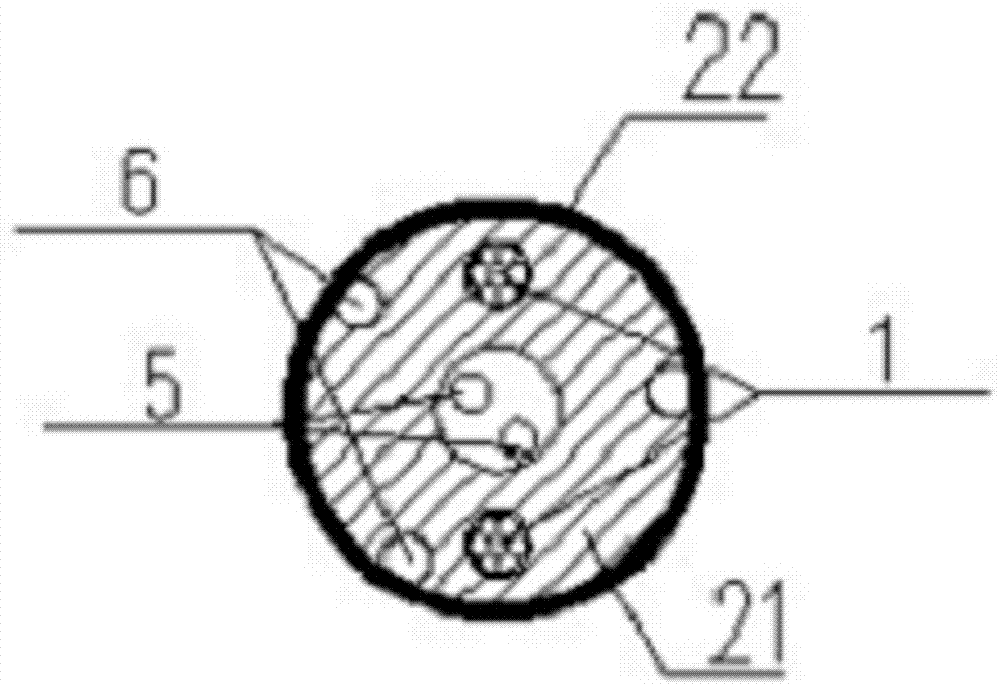

[0036] according to figure 1 , figure 2 , image 3 As shown, a post-grouting pressure anchor rod includes: a tie rod 1, the end of the tie rod 1 is provided with a threaded joint, the threaded joint passes through the tie rod hole on the bearing plate 3, and is fixed by a threaded sleeve 4, the lower part of the tie rod 1 A grouting body 2 is provided;

[0037] The tie rod 1 is a strip-shaped tensionable part, generally a steel bar or a steel strand;

[0038] Described grouting body 2 is made up of common grouting body 21 and post-pressing grouting body 22 of different materials, and common grouting body 21 is conventional concrete mortar, and post-pressing grouting body 22 is high molecular polymer mixed mortar, and grouting body 21 grouting through the grouting pipe 5, and the back grouting body 22 is grouted through the back grouting pipe 6;

[0039] The post-press grout 22 includes: epoxy emulsion, curing agent, cement, filler;

[0040] The bearing plate 3 is fixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com