Multistation hydraulic group control energy-saving technology

A hydraulic and technical technology, applied in the field of group control energy-saving transformation, can solve the problems of large space occupied by the central hydraulic station, low energy-saving efficiency, high energy consumption of large horse-drawn carts, etc., to reduce system internal leakage loss, reduce system pressure, Effect of reducing no-load power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

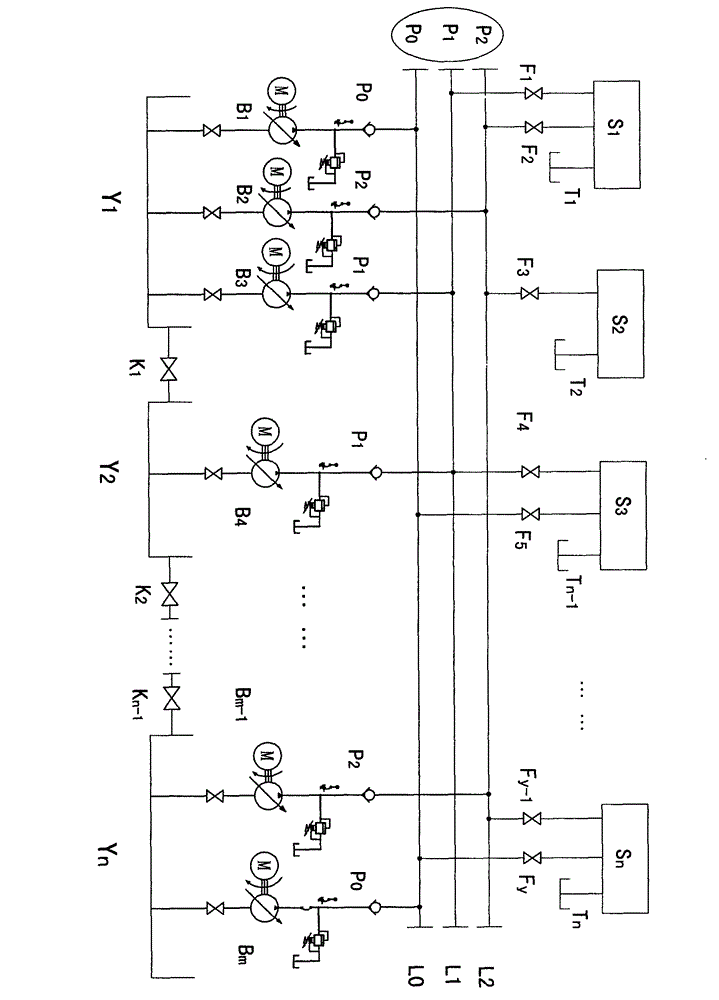

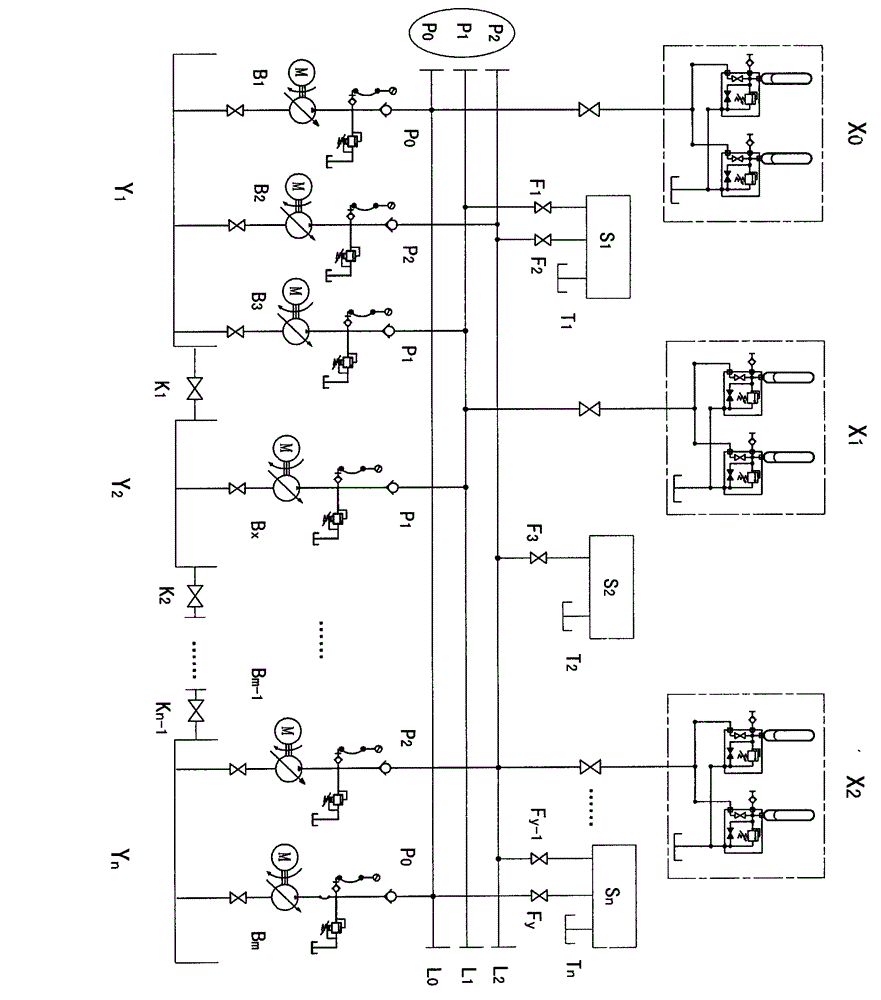

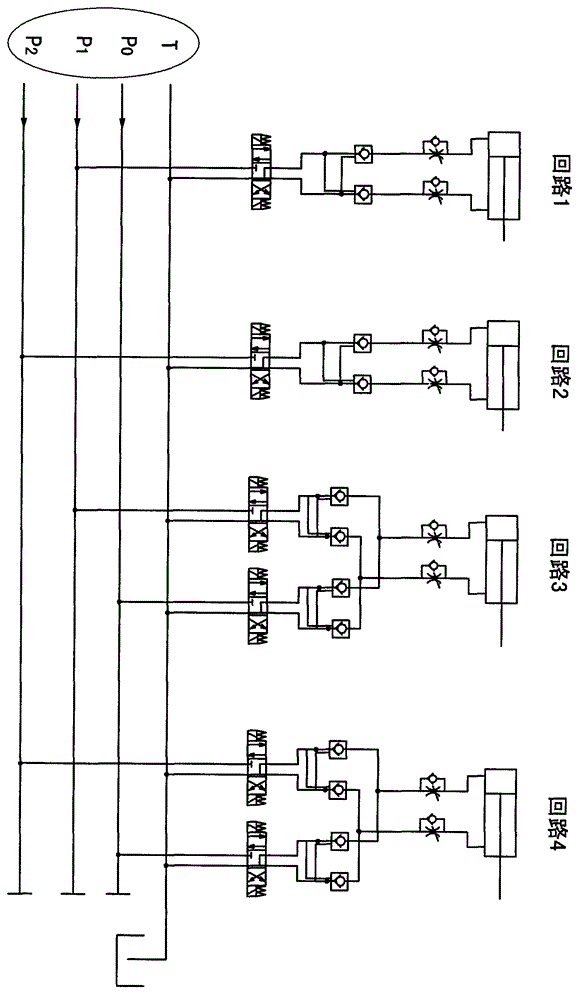

[0020] 1. Single equipment multi-hydraulic station networking mode

[0021] In a certain area, all or part of the group equipment is connected to the hydraulic system for energy-saving transformation. The function and structure of these group equipment can be the same or different.

[0022] 1.1. Networking mode of fuel tanks in hydraulic stations

[0023] Connect the oil tanks of all single equipment hydraulic stations that need to be transformed. Generally, the bottom or upper part of the oil tanks is connected with pipelines, so that the hydraulic oil in each oil tank can flow freely with each other. It should be noted that the highest position of each oil tank The allowable liquid level should be roughly in one plane, and the minimum allowable liquid level at the bottom of the fuel tank should not be too different to prevent the high-level fuel tank from being sucked or the low-level fuel tank from being filled with overflow. Each fuel tank is filled with the same hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com