Sewage sludge and household garbage mixed incinerating device based on grate furnace

A technology for domestic waste and incineration equipment, which is applied in the direction of incinerators, combustion methods, and combustion types, etc., can solve the problems of high construction and operation costs, and achieve the effects of reduced construction and operation costs, stable and complete combustion, and promotion of disturbance and combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

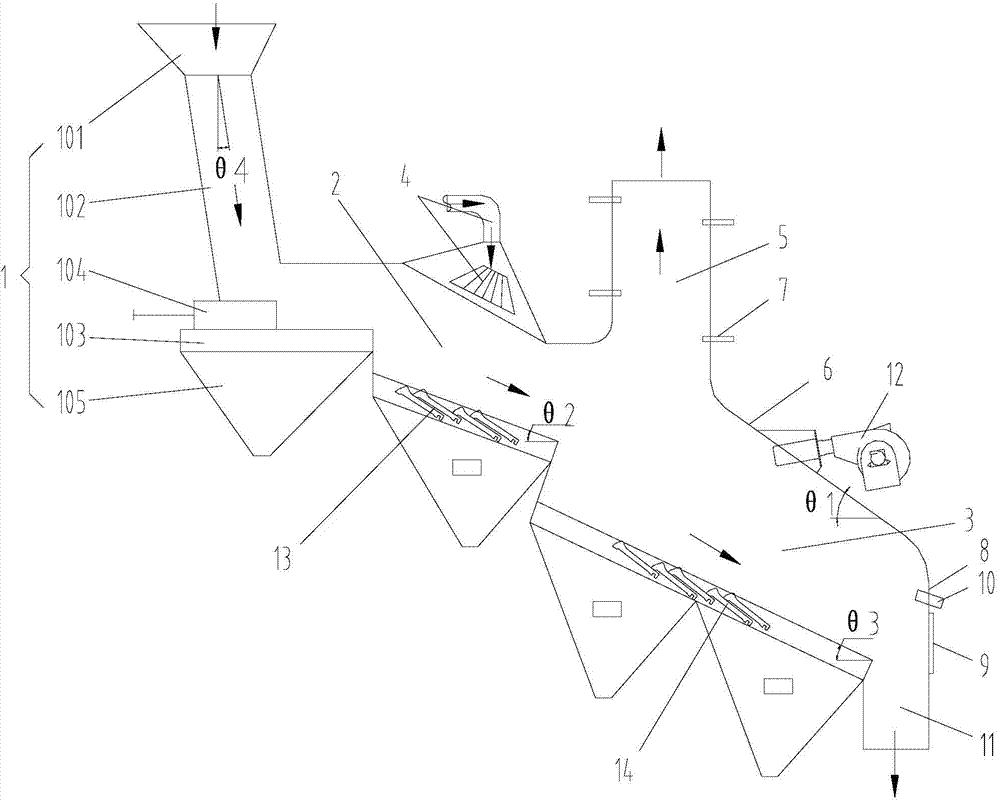

[0023] As shown in the figure, this embodiment is based on the sludge and domestic waste mixed incineration device of the grate furnace, which includes a feeding device 1 and a double-hearth grate furnace. The double-hearth grate furnace includes a drying section grate 13, a drying section Furnace 2, combustion section fire grate 14 and combustion section fire hearth 3, the feed port of described drying section fire grate 13 is connected with the discharge port of feeding device 1, the discharge port of described drying section fire grate 13 and combustion section The feed port of the grate 14 is connected, and the top of the furnace 2 of the drying section is provided with a sludge spraying device 4 .

[0024] When working, the garbage enters the grate 13 of the drying section through the feeding device 1, and the sludge is sprayed on the garbage throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com