Side-by-side side-pump coupler and preparation method thereof

A coupler and side pumping technology, applied in the field of optical fiber devices, can solve the problems of difficult post-processing stripping, large pump coupling loss, cumbersome manufacturing process, etc., and achieve outstanding substantive features, small coupling loss, and power expansion. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

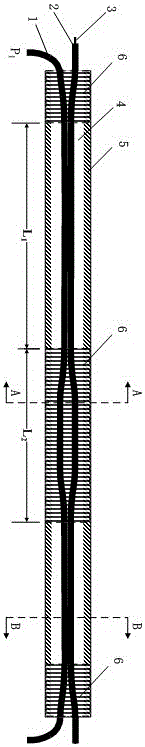

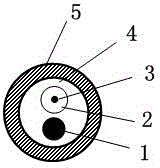

[0033] exist figure 1 Among them, the side-by-side pumping coupler of the present invention includes a pumping fiber 1 , a gain fiber inner cladding 2 , a gain fiber core 3 , an inner cladding 4 , a protective coating 5 and a strippable marker 6 . Wherein, the gain fiber core 3 is arranged in the inner cladding 2 of the gain fiber, the pumping fiber 1 and the inner cladding 2 of the gain fiber are arranged side by side in parallel, and the outer cladding 4 covers the periphery of the pumping fiber 1 and the inner cladding 2 of the gain fiber, The protective coating 5 is covered on the periphery of the outer cladding 4, and the strippable mark 6 is arranged on the top of the protective coating 5 in the strippable region of the pump coupler, as a strippable mark for the pumping fiber 1 and the inner cladding 2 of the gain fiber; The area where the optical fiber inner cladding 2 and the pumping optical fiber 1 contact each other forms a coupling area. During operation, the pumpi...

Embodiment 2

[0045] Such as Figure 7 As shown, the basic structure and preparation method of the shoulder-by-shoulder side-pump coupler in this embodiment are the same as those in Example 1. There are 3 special optical fibers with 3 strippable marks 6 at both ends and the middle, and the outer protective coating 5 and outer cladding 4 at the two ends and the middle section of the special optical fiber in the strippable area are removed, and the two ends and the middle section of the special optical fiber are The bare pump fiber 1 in the strippable area is stripped from the gain fiber inner cladding 2, and the pump fiber 1 in the middle section is cut from the middle position, and then the pump fiber 1 and the gain fiber inner cladding 2 after stripping are separated. A layer of outer cladding coating is evenly coated on the outside, which constitutes a side-by-side pump coupler with a length of about 30m, a pump fiber arranged side by side with the inner cladding of the gain fiber, and 4 ...

Embodiment 3

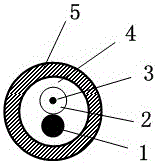

[0047] Such as Figure 8 As shown, the basic structure and preparation method of the side-by-side pump coupler in this embodiment are the same as those in Example 1, the difference is that the side-by-side pump coupler is prefabricated with two pump fibers The number of pump fibers 1 arranged side by side with the gain fiber inner cladding 2 in the side-by-side pump coupler obtained after preparation is two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com