Overhead transmission line cleaning robot

A technology for overhead transmission lines and cleaning robots, which is applied to overhead line/cable equipment, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as inability to walk, heavy load on mechanical arms, and no protection devices, to prevent accidents The effect of polluting the environment, safe sealing, fast and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment is carried out under the premise of technical scheme of the present invention, has provided detailed embodiment and concrete operation process, but protection scope of the present invention is not limited to following the described embodiment.

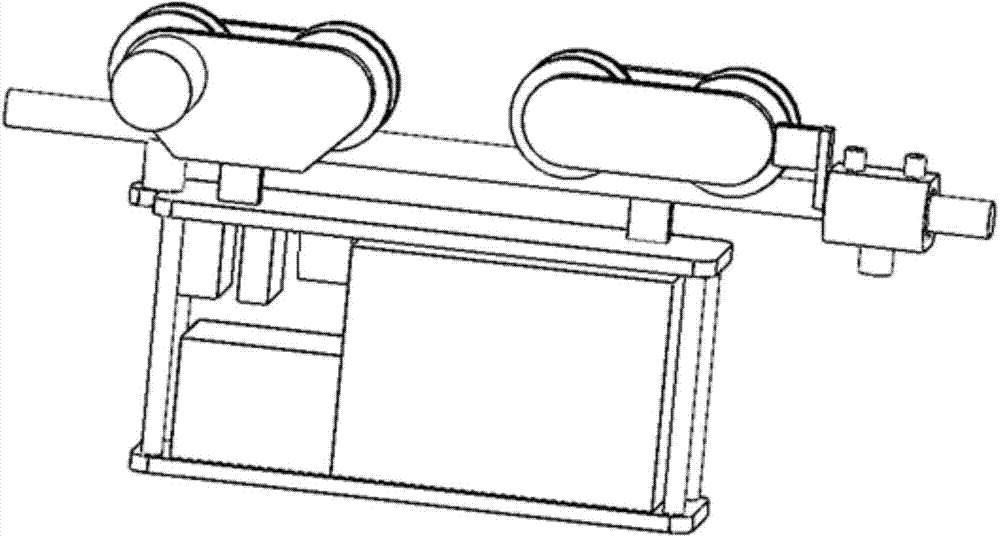

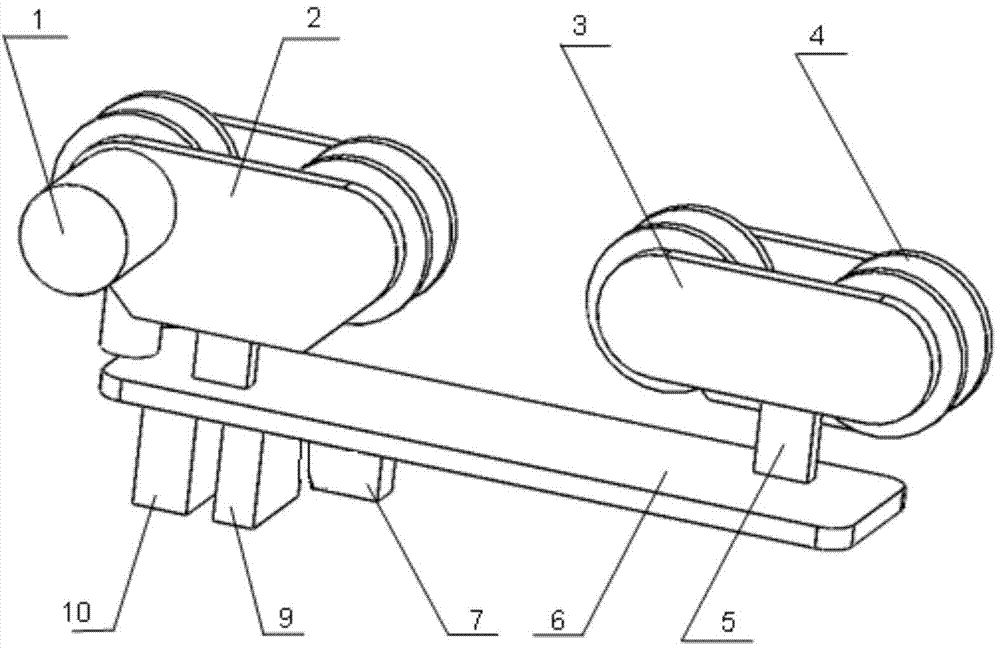

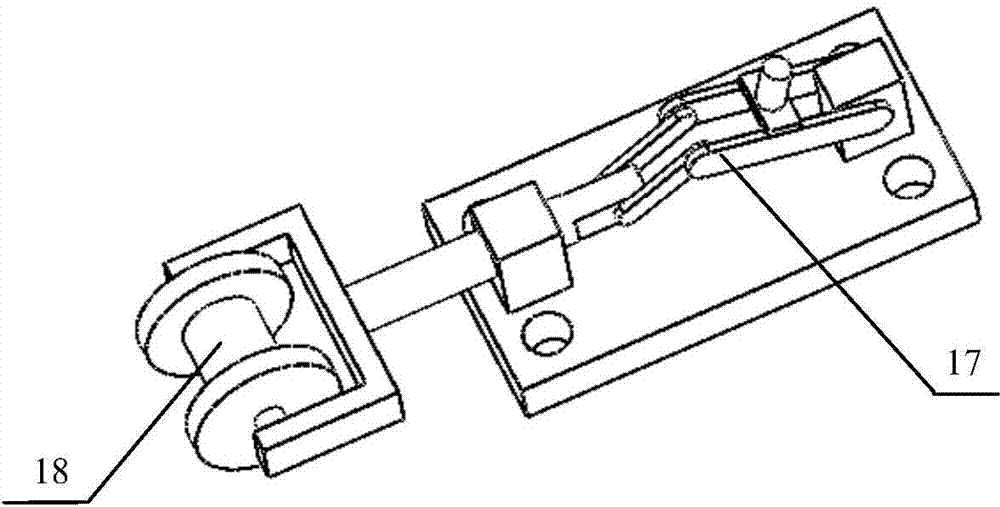

[0026] Such as figure 1 As shown, the present embodiment includes: a mobile car body, a power supply module, a cleaning motor, a servo driver, a pressing device and a cleaning device, etc. Among them: the mobile car body is suspended on the overhead power transmission line, and moves back and forth along the overhead power transmission line, the power module, cleaning motor, servo driver and pressing device are installed on the upper cover, and the upper cover and the lower cover are connected by a bracket. The recovery bucket and the cleaning agent bucket are installed on the lower cover.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com