Method of extracting, purifying and inhibiting alpha-glucosaccharase active ingredient from chestnut shell

A technology of glucosidase, active ingredient, applied in the field of natural product chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) 100g of chestnut shells were washed, dried and crushed, and 75% (v / v) ethanol was added according to the ratio of material to liquid 1:10 (w / v) and boiled and refluxed twice, each time for 2 hours;

[0017] (2) Combine the chestnut shell extracts and concentrate under reduced pressure at 50°C for 2 hours to obtain a concentrated extract;

[0018] (3) The concentrated extract was prepared into a 10 mg / mL solution with water, and then extracted 3 times with 4 times the volume of water-saturated n-butanol, each time for 2 hours;

[0019] (4) Combine the water-saturated n-butanol extracts, concentrate under reduced pressure at 70°C for 2 hours to obtain a concentrated extract, and then freeze-dry at -70°C for 10 hours to obtain 0.5g of powdery extract;

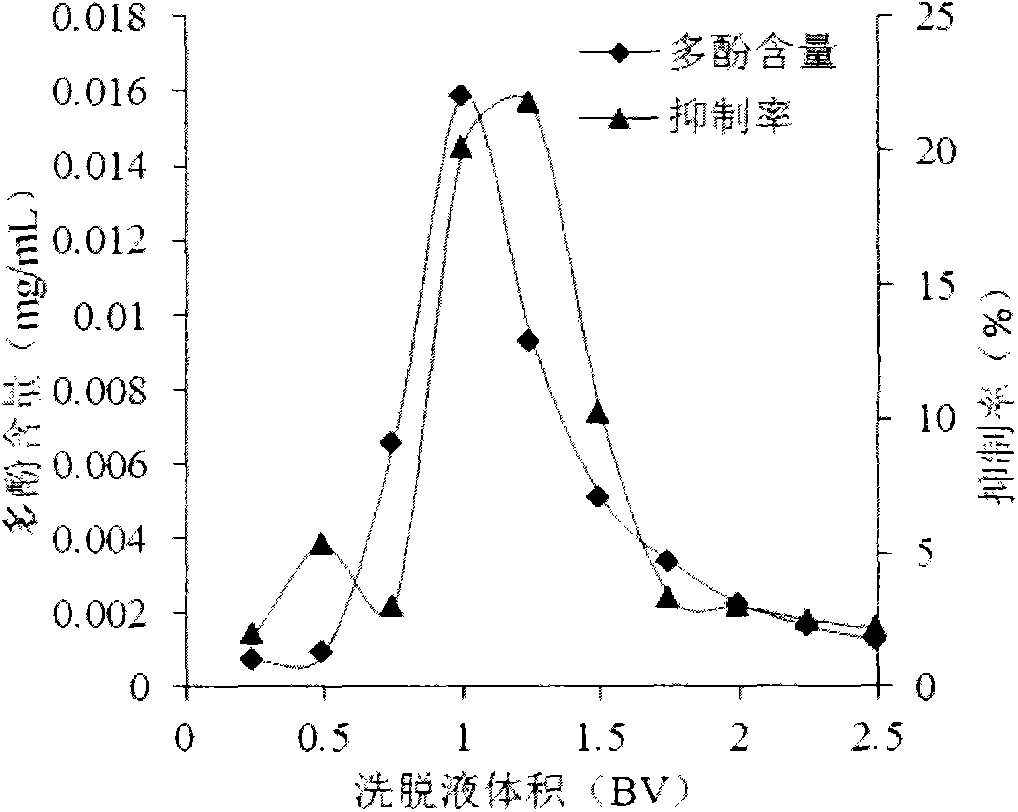

[0020] (5) The powdery extract was made into a 0.5 mg / mL solution with water, adsorbed with macroporous resin AB-8, eluted with 60% (v / v) ethanol at a flow rate of 1 BV / h, and collected the eluate;

[0021] (6) measure...

Embodiment 2

[0023] (1) 10kg of chestnut shells were washed, dried and crushed, and 75% (v / v) ethanol was added according to the ratio of material to liquid 1:10 (w / v) and boiled and refluxed for 3 times, each time for 4 hours;

[0024] (2) Combine the chestnut shell extracts and concentrate under reduced pressure at 50°C for 4 hours to obtain a concentrated extract;

[0025] (3) The concentrated extract was prepared into a 10 mg / mL solution with water, and then extracted 5 times with 4 times the volume of water-saturated n-butanol, each time for 4 hours;

[0026] (4) Combine the water-saturated n-butanol extracts, concentrate under reduced pressure at 80°C for 4 hours to obtain a concentrated extract, and freeze-dry at -90°C for 24 hours to obtain 50 g of powdery extract;

[0027] (5) The powdery extract was made into a 0.5 mg / mL solution with water, adsorbed with macroporous resin AB-8, eluted with 60% (v / v) ethanol at a flow rate of 1 BV / h, and collected the eluate;

[0028] (6) Measur...

Embodiment 3

[0030] (1) 100kg of chestnut shells were washed, dried and crushed, and 75% (v / v) ethanol was added according to the ratio of material to liquid 1:10 (w / v) and boiled and refluxed twice, each time for 3 hours;

[0031] (2) Combine the chestnut shell extracts and concentrate under reduced pressure at 50°C for 3 hours to obtain a concentrated extract;

[0032] (3) The concentrated extract was prepared into a 10 mg / mL solution with water, and then extracted 4 times with 4 times the volume of water-saturated n-butanol, each time for 3 hours;

[0033] (4) Combine the water-saturated n-butanol extracts, concentrate under reduced pressure at 75°C for 3 hours to obtain a concentrated extract, and then freeze-dry at -80°C for 12 hours to obtain 450g of powdery extract;

[0034] (5) The powdery extract was made into a 0.5 mg / mL solution with water, adsorbed with macroporous resin AB-8, eluted with 60% (v / v) ethanol at a flow rate of 1 BV / h, and collected the eluate;

[0035] (6) Measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com