Instant natural fruit and vegetable powder and making method thereof

A production method and technology of fruit and vegetable powder, applied in the direction of food science, etc., can solve the problems of easy precipitation of fruit and vegetable powder, lack of flavor, etc., and achieve the effects of rich products, good taste, and easy digestion and absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

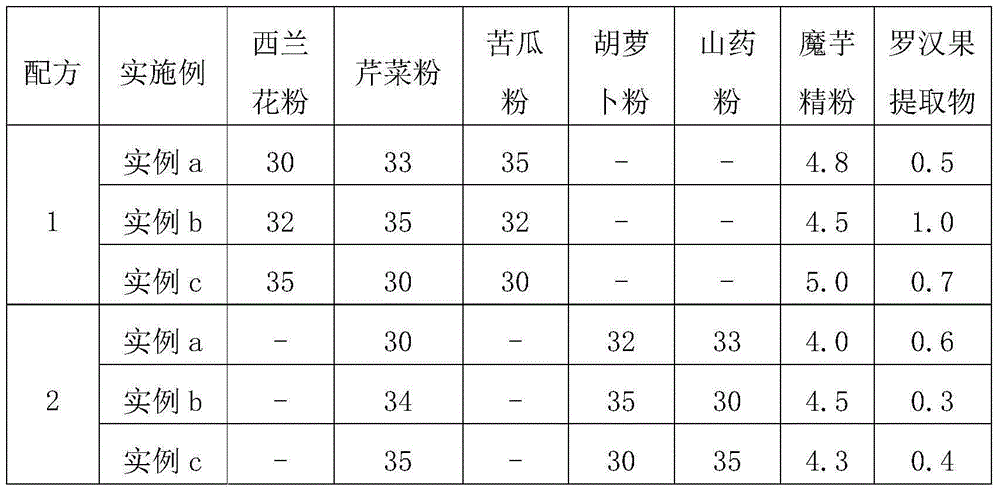

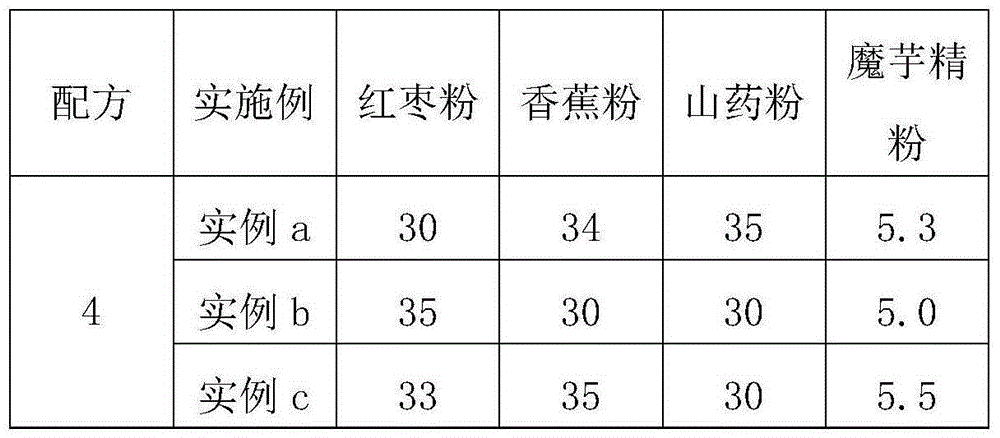

Examples

Embodiment 1

[0034] A manufacturing method of instant natural green vegetable powder, its specific manufacturing steps include:

[0035] (1) Selected raw materials for fruits and vegetables: select fresh broccoli, celery and bitter gourd raw materials with bright green color, no pollution, and fresh;

[0036] (2) Pretreatment: Soak the selected vegetable raw materials in 1-1.5% salt water for 3-5 minutes to remove dust, sand, insects, insect eggs, microorganisms and some residues attached to the raw materials Broccoli is cut into pieces, the size of the flower bulb is 10-12mm, the size of the flower stem is 4-6mm, the bitter gourd is cut and the celery is sliced, the size is 4-6mm; because the raw material contains unpleasant herbaceous substances, the The cut vegetable raw materials were blanched in a solution of sodium bicarbonate containing 0.5%-1% at 80-95℃ for 2-5 minutes, then quickly put into a cooling tank, and cooled to 10 in flowing cold water at 5℃. Below ℃, remove and drain;

[0037...

Embodiment 2

[0045] A manufacturing method of instant natural vitamin C fruit and vegetable powder, its specific manufacturing steps include:

[0046] (1) Selected raw materials for fruits and vegetables: select tomatoes, citrus, mangoes and red dates that are pollution-free, fresh, and mature at over 80%;

[0047] (2) Pretreatment: Use running water to remove the dust, soil, microorganisms and some residual chemical pesticides on the skin of the selected fruit and vegetable raw materials, remove and drain; remove the red dates and mangoes. After peeling and citrus, the raw fruits and vegetables are crushed and pulped separately, and are rapidly heated to 80-85℃ for 15-20 seconds, then filtered, peeled and seeded; homogenize the slurry with a homogenizer at a homogenization pressure of 30- 40MPa;

[0048] (3) Drying: Put the fruit and vegetable raw materials obtained through the pretreatment into the quick-freezing warehouse for quick-freezing. It is required that the center temperature of the r...

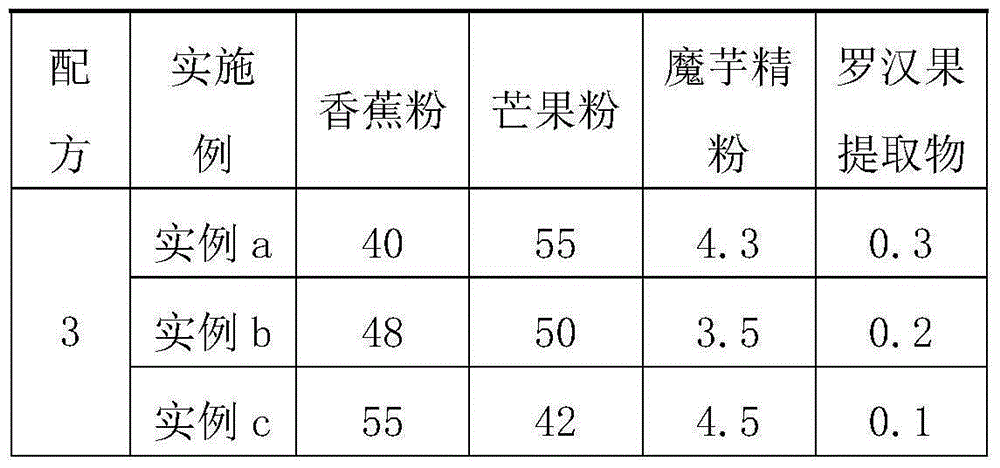

Embodiment 3

[0055] A manufacturing method of instant natural high-fiber fruit and vegetable powder, its specific manufacturing steps include:

[0056] (1) Selected raw materials for fruits and vegetables: select pollution-free, fresh, and high-quality corn, carrots, yams, and bananas; preferably sweet corn;

[0057] (2) Pretreatment: Use running water to remove the dust, soil and microorganisms on the epidermis of the selected fruit and vegetable raw materials, corn core, carrot, yam and banana peel, carrot, banana and yam slice; Blanch it in 1% -1.5% salt water at 95-100℃ for 5-8 minutes, quickly put it in a cooling tank, cool it in flowing cold water at 5℃ to below 10℃, remove and drain; among them, for those containing fibrous tissue When slicing yam, the cut surface should be perpendicular to the fibrous tissue so that water can escape during the freeze-drying process. The size is 3-5mm;

[0058] (3) Drying: Put the fruit and vegetable raw materials obtained through the pretreatment into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Broken particle size | aaaaa | aaaaa |

| Broken particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com