Preparation method of molecularly-imprinted magnetic silica microsphere with hydrophilic external surface

A technology of silica gel microspheres and molecular imprinting, applied in chemical instruments and methods, ion exchange, ion exchange regeneration, etc., can solve problems such as low separation efficiency, high impurity content, and large detection interference, and achieve uniform particle size and selectivity Strong, enriched strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

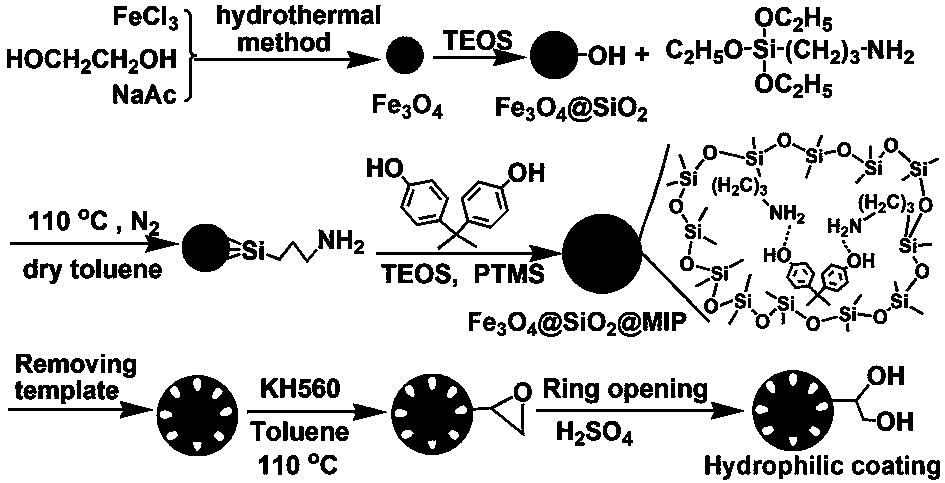

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of magnetic silica gel microspheres: weigh 0.5 g Fe 3 o 4 , add 80 ml ethanol and 20 ml distilled water mixed solvent, then adjust the pH value of the solution with 2.5 ml ammonia water (25-28%, w / w) to keep the pH value of the solution between 8-9, ultrasonically disperse After 5 min, 2 ml of tetraethoxysilane was added dropwise, and mechanically stirred at room temperature for 12 h. The product was collected, washed 3-4 times with distilled water, and dried at 60°C for 12 h to obtain magnetic silica gel microspheres. figure 2 (c) shown. From figure 2 It can be seen from the comparison that figure 2(c) The synthesized magnetic silica gel microspheres have good dispersibility, uniform particle size and beautiful appearance.

[0029] (2) Preparation of aminated magnetic silica gel microspheres: Disperse 0.5 g of magnetic silica gel microspheres into 50 ml of anhydrous toluene, then add 2 ml of silane KH-550, and reflux for 8 h under the protection...

Embodiment 2

[0034] When preparing magnetic silica gel microspheres, 90 ml of ethanol and 10 ml of distilled water were used as the reaction solvent, and the rest of the steps were the same as in Example 1. The scanning electron microscope images of the prepared magnetic silica gel microspheres are as follows: figure 2 (a) shown.

Embodiment 3

[0036] When preparing magnetic silica gel microspheres, 50 ml of ethanol and 50 ml of distilled water were used as the reaction solvent, and the rest of the steps were the same as in Example 1. The scanning electron microscope images of the prepared magnetic silica gel microspheres are as follows: figure 2 (b) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com