Inorganic waterproof material with high impervious performance

A waterproof material, inorganic technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of waterproof material can not meet the impermeability performance, etc., to shorten the setting time, increase the density, improve the resistance The effect of osmotic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

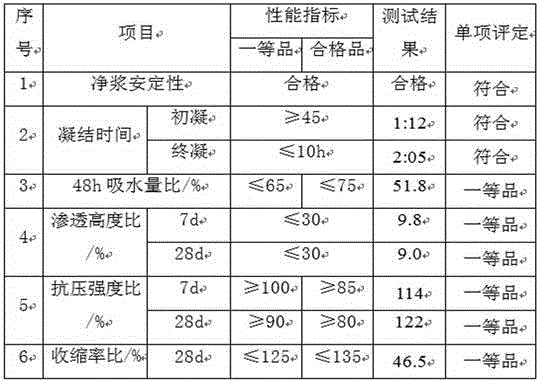

[0018] The inorganic waterproof material with high impermeability of the present invention is composed of raw material No. 42.5 ordinary Portland cement, fine river sand with a fineness modulus of 2.00-2.10, and particles with a particle size of less than 45 μm accounting for more than 88% Grade I fly ash, silicon powder with an average particle size of less than 0.1μm, FEA expansion agent or UEA expansion agent or MgO expansion agent, FDN water reducing agent or UNF water reducing agent or ZF water reducing agent and ferric chloride according to the following Parts by weight: 71~75 parts of Portland cement, 144~152 parts of fine river sand, 11~13 parts of grade I fly ash, 2~4 parts of silica fume, 11~13 parts of expansion agent Parts, 3 parts of ferric chloride and 1 part of water reducing agent.

[0019] When in use, various raw materials are weighed according to the amount used in the project, and the weight ratio of the raw materials is slightly adjusted according to the diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com