A kind of chemical preparation method of bi4lati3feo15 multiferroic film

A multiferroic thin film and chemical technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of ferroelectric performance deterioration, leakage current increase, and inability to obtain ferroelectric loops, etc., to achieve ferroelectricity Improved performance, excellent ferroelectric properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of precursor sol: with analytically pure bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), lanthanum oxide (La 2 o 3 ), iron acetylacetonate (C 15 h 21 FeO 6 ) and butyl titanate (Ti(C 4 h 9 O) 4 ) etc. as the main raw materials; according to Bi 4 LaTi 3 FeO 15 Weigh various raw materials that meet the stoichiometric ratio and configure them; in order to compensate for the volatilization of Bi elements in the subsequent heat treatment process, Bi(NO 3 ) 3 ·5H 2 O excess 4mo1%, specific steps are:

[0026] (1) Mole ratio La: HNO 3 =1:20 measure concentrated HNO 3 , and then La 2 o 3 Add to concentrated HNO 3 , placed on a magnetic stirrer and stirred until the solution was clear;

[0027] (2) Molar ratio Bi:CH 3 COOH=1:20 measure CH 3 COOH, then Bi(NO 3 ) 3 ·5H 2 O joins CH 3 COOH, placed on a constant temperature magnetic stirrer at 55°C and heated and stirred for 1.5h to remove Bi(NO 3 ) 3 ·5H 2 water of crystallization in O, to which C...

Embodiment 2

[0035] The rest is the same as in Example 1, step 1 (3) adding ethylene glycol methyl ether to make the solution volume 0.1mol / L.

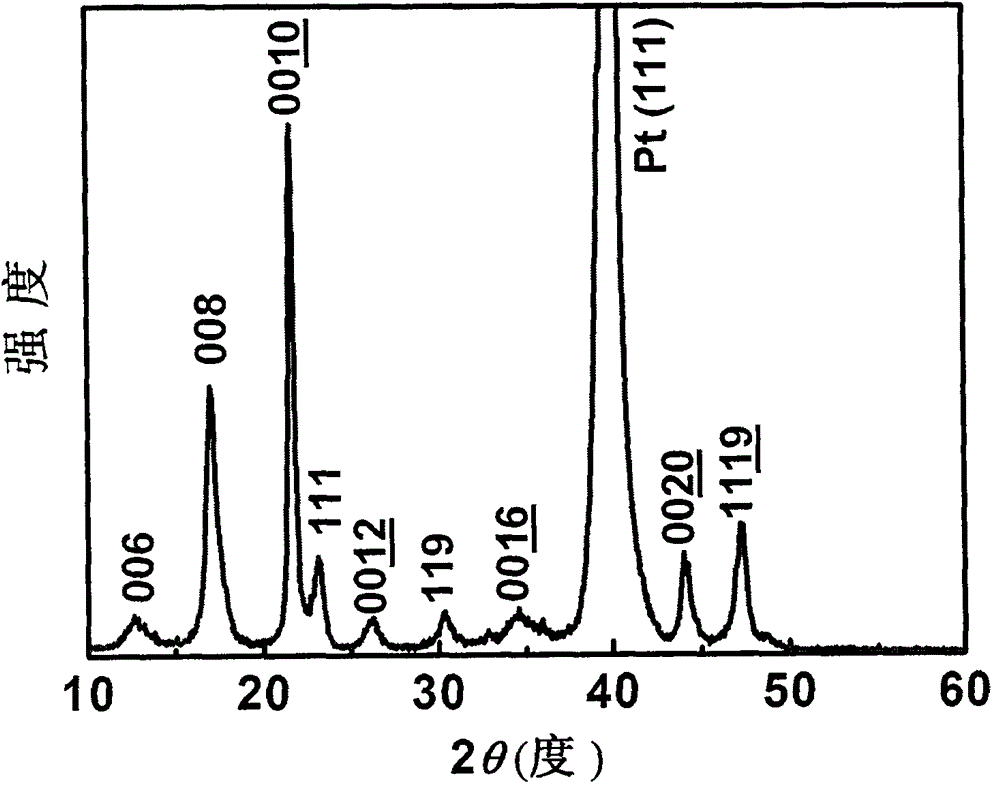

[0036] The Bi prepared in this example 4 LaTi 3 FeO 15 The film phase is pure, and the grains are c-axis oriented (by the attached figure 2 shown); the remnant polarization of the film is 1.4 μC cm -2 , the squareness of the ferroelectric loop is 0.59 (by the attached Figure 5 shown); at 80V, the leakage current is 1.2×10 -4 A / cm 2 (by attached Figure 7 shown).

Embodiment 3

[0038] The rest is the same as in Example 1, step 3 is rapidly raised to 700°C at a rate of 60°C / s.

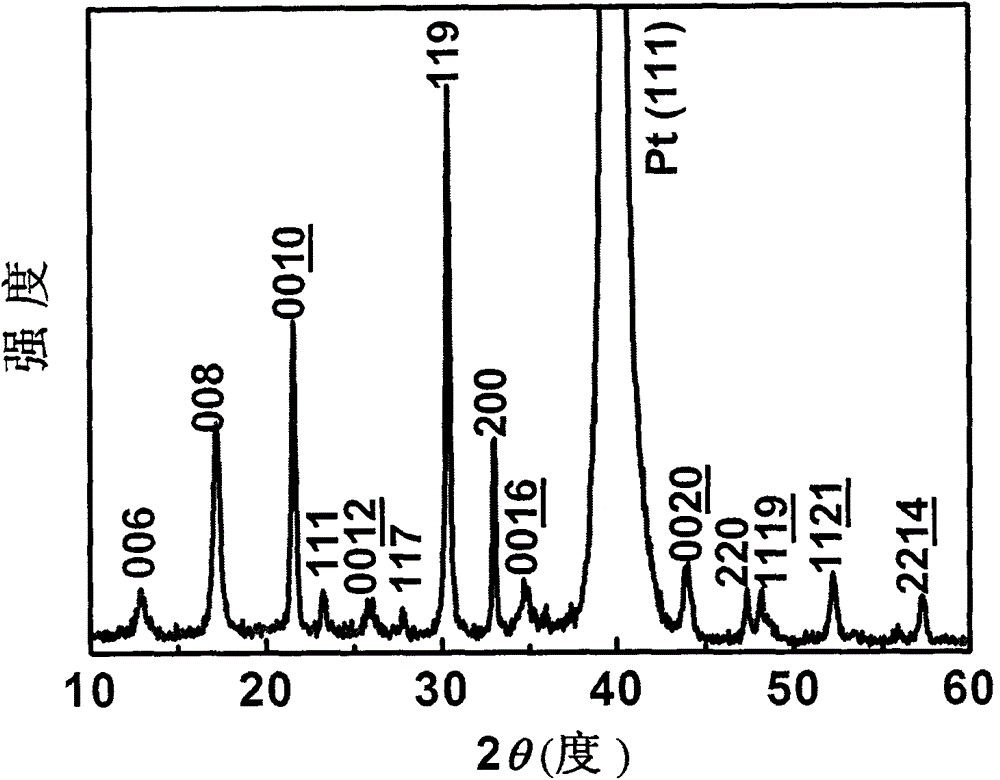

[0039] The Bi prepared in this example 4 LaTi 3 FeO 15 The film has a small amount of impurity, and the grains are randomly oriented (by the attached figure 1 shown); the remnant polarization of the film is 11.4μC cm -2 , the squareness of the ferroelectric loop is 0.73 (by the attached Image 6 shown); the leakage current at 80V is 1.5×10 -4 A / cm 2 (by attached Figure 7 shown).

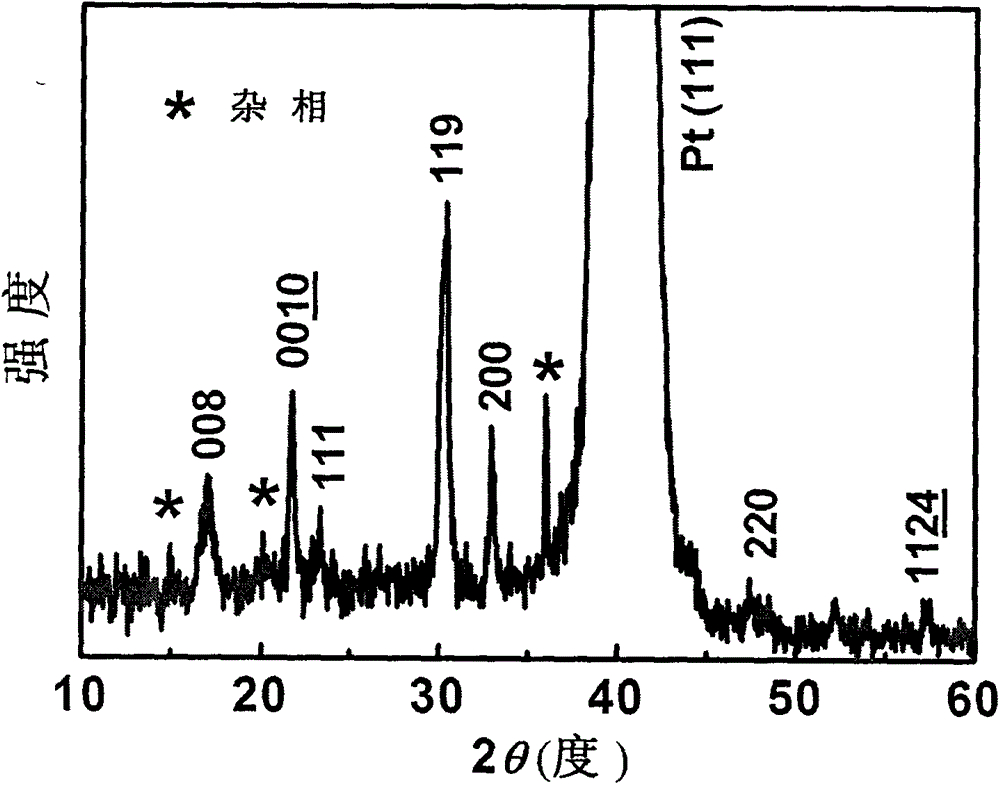

[0040] Bi 4 LaTi 3 FeO 15 Due to the insertion of magnetic groups, the leakage current of multiferroic thin films increases, resulting in the deterioration of their ferroelectric properties, which cannot meet the application requirements. In addition, the chemical composition of the thin film is relatively complex, and the preparation process is prone to generate heterogeneous phases. Therefore, a phase-pure Bi with excellent ferroelectric properties was prepared. 4 LaTi 3 FeO 15 Mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com