Aqueous two-phase method for efficiently extracting phycoerythrin

A phycoerythrin, two-phase technology, which is applied in the preparation method of peptides, algae/moss peptides, chemical instruments and methods, etc., achieves the effects of fast mass transfer, low cost and mild separation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

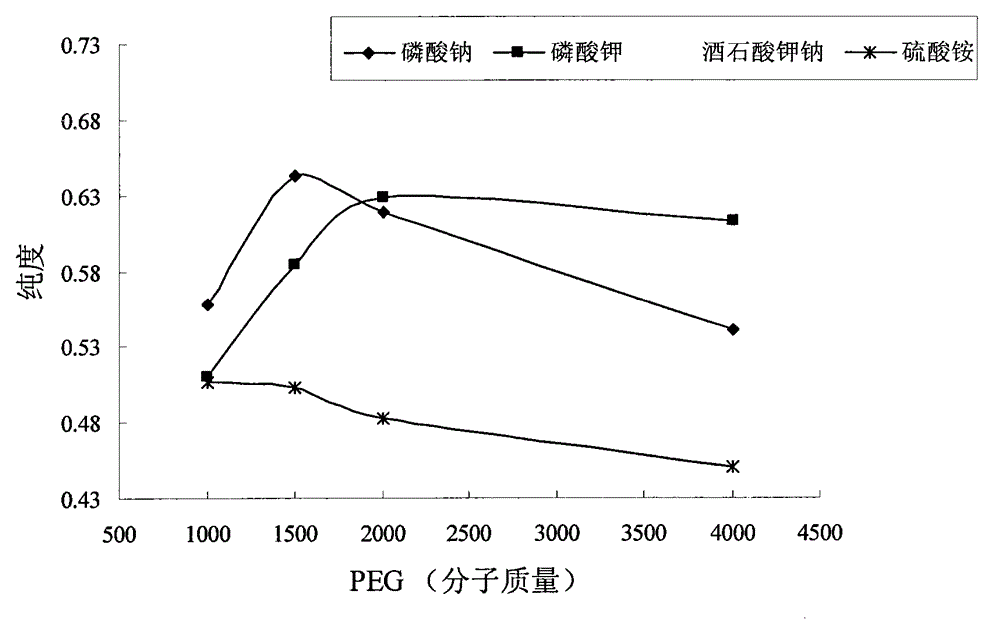

[0020] figure 1 Four different salts are compared in : sodium phosphate, potassium phosphate, potassium sodium tartrate, ammonium sulfate. In the comparison of different PEG molecular weights, potassium sodium tartrate has the highest purity.

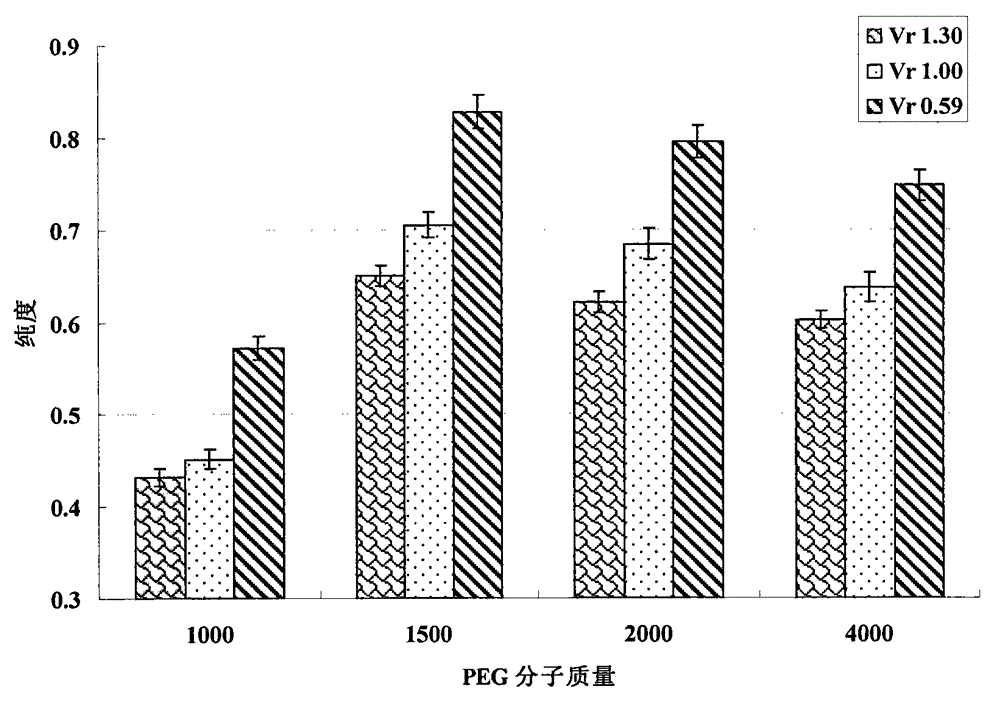

[0021] figure 2 Four different PEG molecular weights were compared: 1000, 1500, 2000, 4000. PEG2000 has the highest purity.

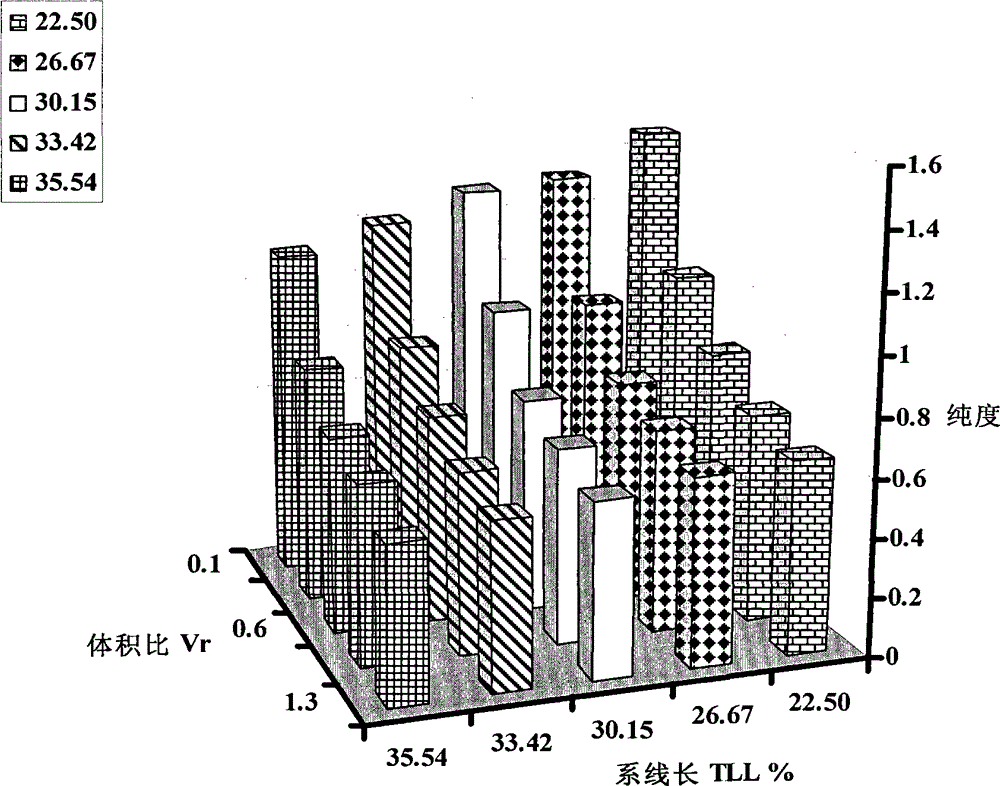

[0022] image 3 Four different tether lengths and different volume ratios were compared: the tether length was 22.5%, and the purity of the volume ratio was 0.33.

[0023] Obtain optimal parameters and establish an efficient two-phase aqueous system. Extract phycoerythrin. The characteristics of simple operation, short extraction time, no selectivity and no secondary pollution make it possible to become a common method for protein separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com