Separation and purification method of sugammadex

A technology for separation and purification of sugammadex, applied in the field of separation and purification of sugammadex, can solve the problems of large amount of solvent, cumbersome recrystallization and purification steps, many structural analogs, etc., and achieves good universality and versatility. , Good market application prospects, mild separation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

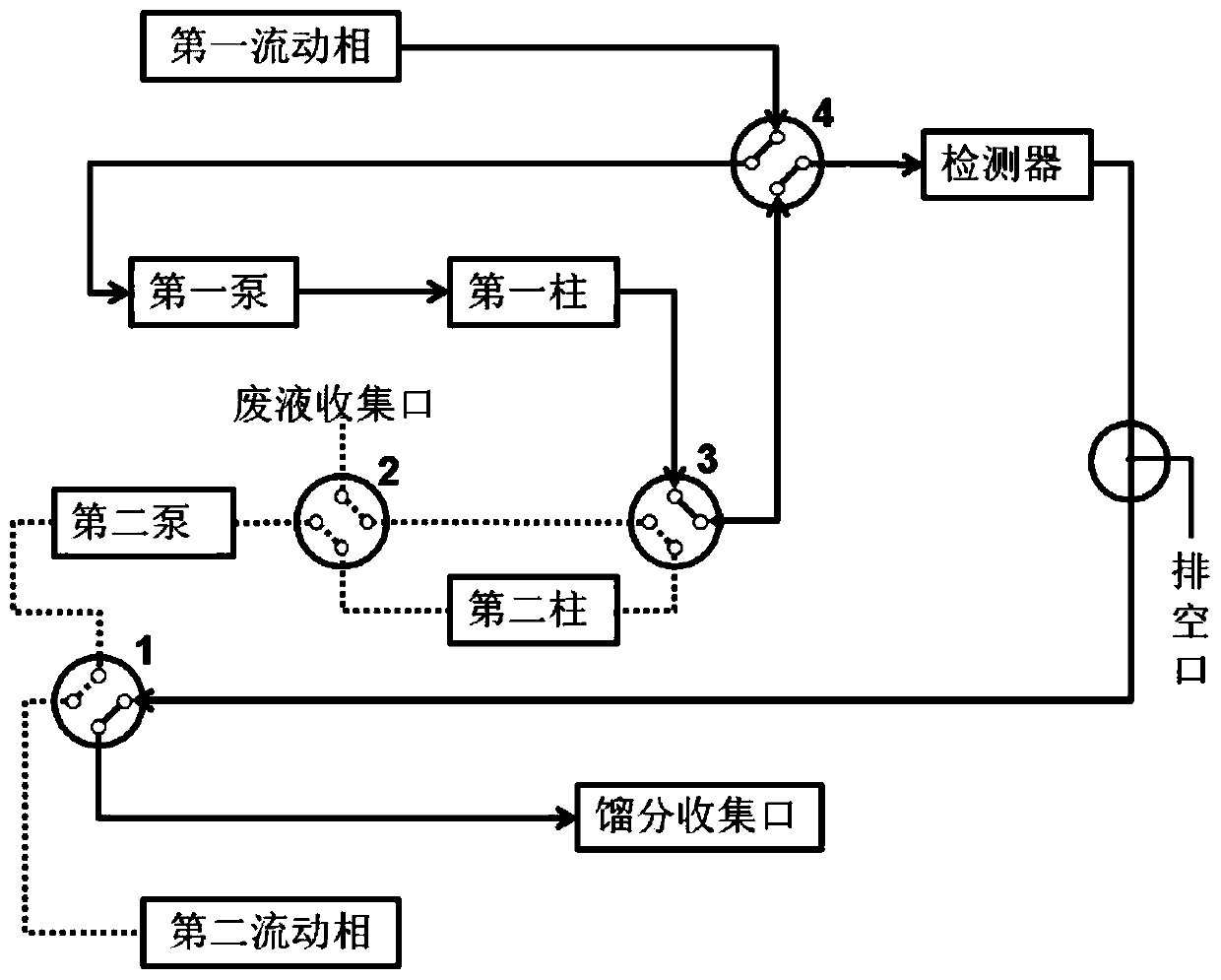

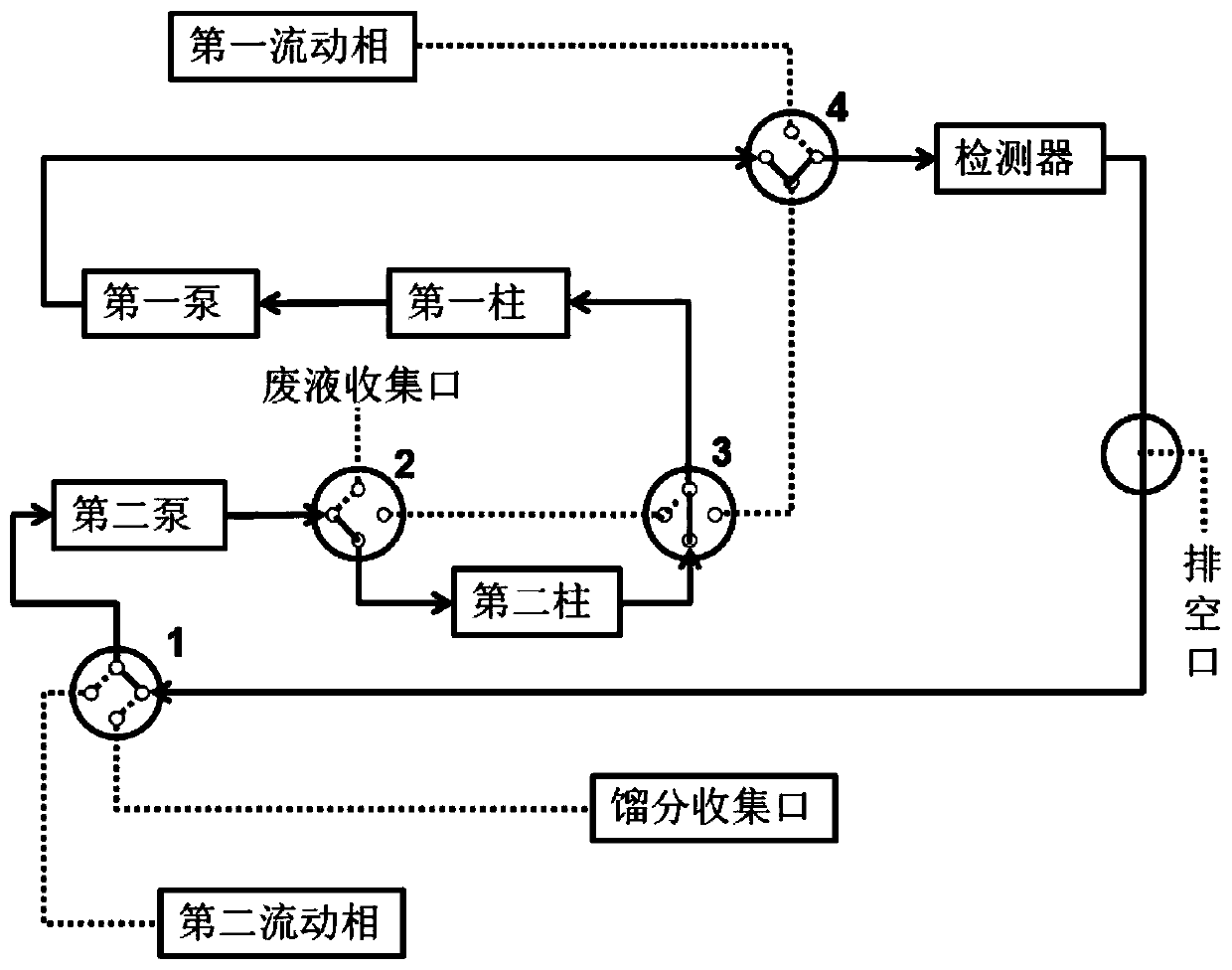

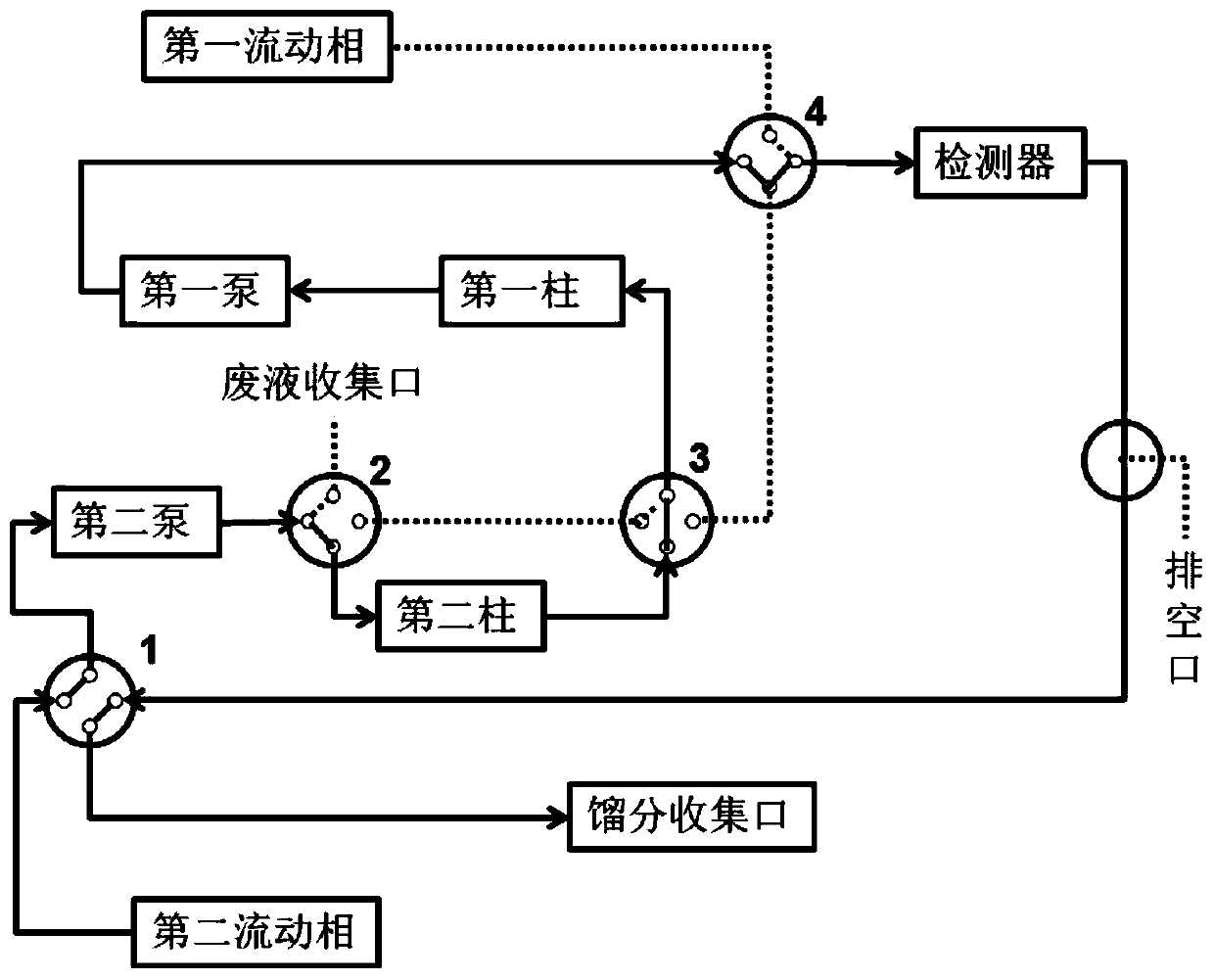

[0076] Separation and purification of sugammadex: Take sugammadex and acetonitrile / water (v / v, 1 / 1) to prepare a solution with a concentration of 50g / 100mL. After the solution was clarified, it was filtered through a filter membrane with a pore size of 0.45 μm, and the filtrate was collected for later use. A self-assembled column is used, and the column packing model is SiliaSphere series ODS, with a particle size of 50 μm and a pore size of 0.1% trifluoroacetic acid aqueous solution was used as mobile phase A, acetonitrile was used as mobile phase B, and the flow rate was 80 mL / min. Such as figure 1 As shown, the equilibration time of the first column and the second column is about 15min, and the crude product loading is carried out by the first pump ( figure 1 ), 45min (the detector detects the target peak), sequentially switch valve 1, valve 2, valve 3 and valve 4 into figure 2 Shown (marked by solid line) is double-column internal circulation mode C. At 75min, turn ...

Embodiment 2

[0080] Separation and purification of sugammadex: Take sugammadex and acetonitrile / water (v / v, 1 / 1) to prepare a solution with a concentration of 50g / 100mL. After the solution was clarified, it was filtered through a filter membrane with a pore size of 0.45 μm, and the filtrate was collected for later use. A self-assembled column is used, and the column packing model is SiliaSphere series ODS, with a particle size of 50 μm and a pore size of 0.1% trifluoroacetic acid aqueous solution was used as mobile phase A, acetonitrile was used as mobile phase B, and the flow rate was 80 mL / min. Such as figure 1 As shown, the equilibration time of the first column and the second column is about 15min, and the crude product loading is carried out by the first pump ( figure 1 ), 35min (the detector detects the target peak) when entering into figure 2 Shown (marked by solid line) is double-column internal circulation mode C. At 55min, turn on the second pump to enter image 3 The two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com