A method for extracting soybean protein and purifying and recovering surfactant

A surfactant and soybean protein technology, applied in chemical instruments and methods, protein composition of vegetable seeds, protein food ingredients, etc., can solve the problem of surfactant residues, hinder the pace of industrialization of reverse micelles, and affect protein safety and other problems, achieving the effect of mild separation conditions, simple and easy method, and reduced influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

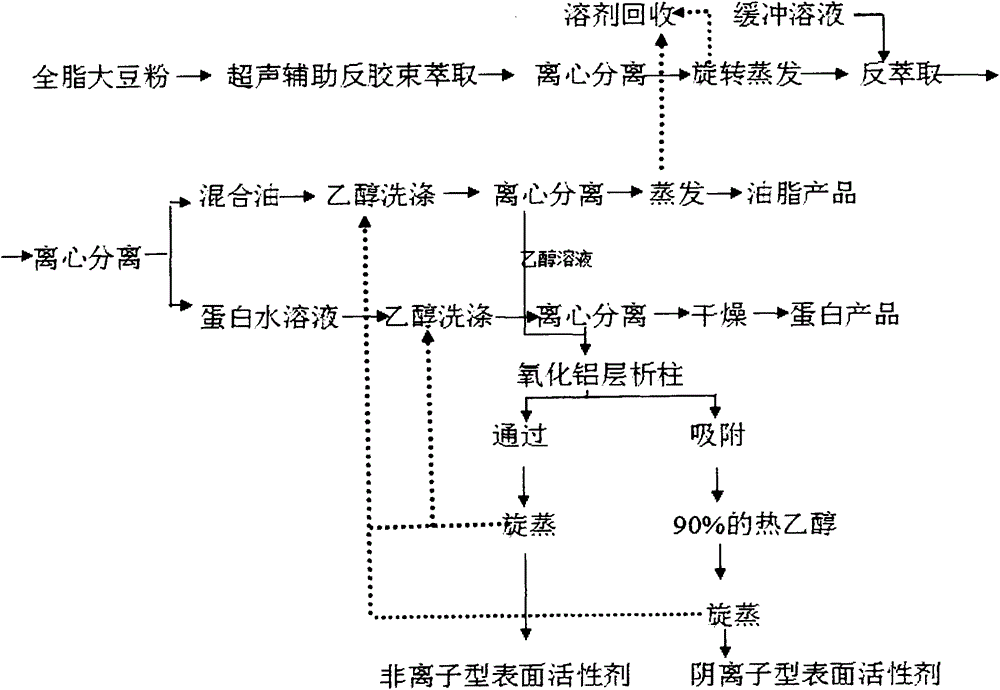

Image

Examples

Embodiment 1

[0039] Add 100g of pretreated full-fat soybean flour to 4L of AOT-Tween60 reverse micellar solution with a concentration of 80g / L and a mass ratio of 7:3. In the reverse micellar solution, the buffer solution is pH 7.0 and KCl concentration 0.10 mol / L KCl-phosphate buffer solution, ultrasonic-assisted extraction, extraction at a temperature of 45°C and a power of 180w for 30min, followed by centrifugation for 10min, the pre-extraction rate of the protein was 85.83%.

[0040] 3.8 L of the protein pre-extract was obtained, and the concentrated solution was obtained by rotary evaporation at 45°C for 2 hours to obtain 1.1 L, and an equal volume of 1.0 mol / L KCl-phosphate buffer solution with an ethanol concentration of 15% was added to adjust the pH value to 8.0, and ultrasonic-assisted extraction was performed. Extract under the conditions of temperature 40°C and power 210w for 30min, then centrifuge for 10min, the upper layer solution is mixed oil, and the lower layer solution is...

Embodiment 2

[0042] Add 15g of pretreated full-fat soybean flour to 500mL of SDS-Tween60 reverse micellar solution with a concentration of 50g / L and a mass ratio of 1:1, and extract with ultrasonic assistance for 30min at a temperature of 35°C and a power of 240w , and then centrifuged for 10 minutes, the pre-extraction rate of protein was 83.62%. 470 mL of the protein pre-extract was obtained, which was rotary evaporated at 45°C for 30 min to obtain 100 mL of the concentrated solution, and an equal volume of 1.2 mol / L KCl-phosphate buffer solution with an ethanol concentration of 15% was added, ultrasonically assisted extraction, and then centrifuged for 10 min. Add 67% ethanol aqueous solution to the mixed oil, vibrate on the shaker for 20 minutes, let it stand for 30 minutes to separate, the oil extraction rate is 90.22%, add 120ml of ethanol with a concentration of 95% to the protein solution, shake on the shaker After 20 minutes, the slurry was freeze-dried after centrifugation to obt...

Embodiment 3

[0044] Add 150g of pretreated full-fat soybean flour to 5L of SDS-Tween85 reverse micellar solution with a concentration of 90g / L and a mass ratio of 6:4, and extract with ultrasonic assistance for 30min at a temperature of 40°C and a power of 210w , and then centrifuged for 10 min, the pre-extraction rate of protein was 89.37%. Obtain 4.8L of protein pre-extract, at 50. Rotary evaporation at C for 3 hours to obtain 1.2 L of concentrated solution, added an equal volume of 1.1 mol / L KCl-phosphate buffer solution with an ethanol concentration of 15%, extracted with ultrasonic assistance, and centrifuged for 10 minutes. Add 67% ethanol aqueous solution to the mixed oil, vibrate on the shaker for 20 minutes, let it stand for 30 minutes to separate, the oil extraction rate is 93.16%, add 1.3L of 95% ethanol to the protein solution, and shake it on the shaker Shake for 20 minutes and centrifuge for 10 minutes. The post-extraction rate of protein was 90.33%, and the total protein e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com