Phosphorus-silicon polymer-containing flame-retardant room-temperature vulcanized silicone rubber composition and preparation method thereof

A silicone rubber composition and room temperature vulcanization technology are applied in the field of materials to achieve the effects of good flame retardant effect, less additive amount, flame retardant effect, halogen-free and environmental protection.

Active Publication Date: 2014-07-30

INST OF CHEM CHINESE ACAD OF SCI

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In actual production and application, a single flame retardant will always have defects of one kind or another, and it is difficult to meet higher and higher requirements with a single flame retardant. Combining two or more flame retardants can be combined The advantages of the above flame retardants can achieve the purpose of reducing the amount of flame retardants, improving the flame retardant performance, processing performance and physical and mechanical properties of materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

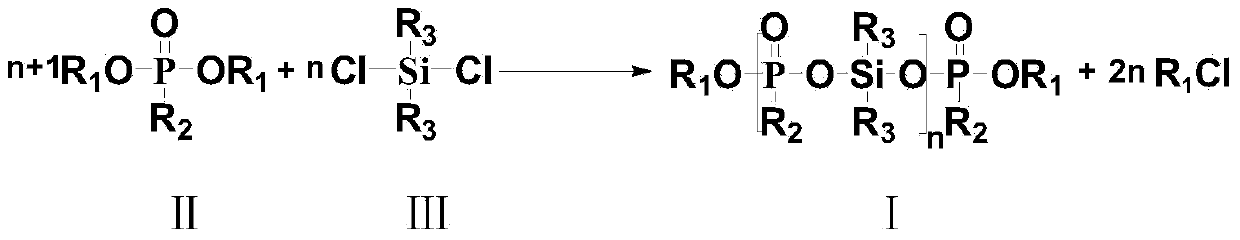

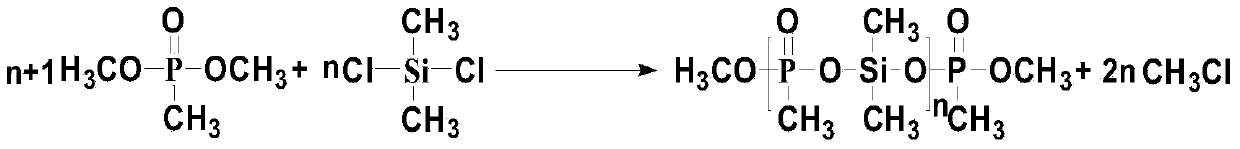

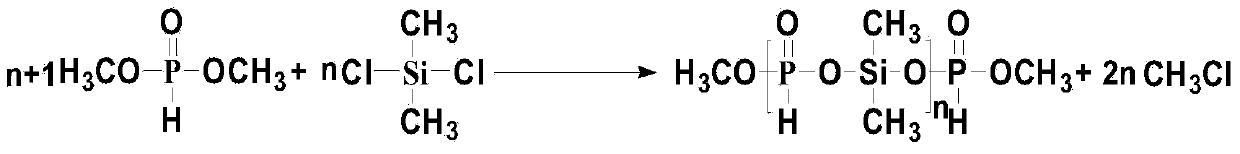

The invention discloses a phosphorus-silicon polymer-containing flame-retardant room-temperature vulcanized silicone rubber composition and a preparation method thereof. The composition is prepared from the following raw materials in parts by mass: 100 parts of polysiloxane, 0.1-20 parts of cross-linking agent, 10-40 parts of inorganic packing, 10-100 parts of reinforcing agent and 0.1-20 parts of phosphorus-silicon polymer, wherein the structural formula of the phosphorus-silicon polymer is as shown in the formula I. When being used together, the phosphorus-silicon polymer and the inorganic packing are good in flame retardance effect, halogen-free and environment-friendly, the use amount of the inorganic packing can be reduced under the condition that an equal flame retardance grade is achieved, the phosphorus-silicon polymer self has a catalysis function in curing the system, no extra catalyst is needed, the addition amount of the phosphorus-silicon polymer is small, and the mechanical property is slightly affected. The formula I is as shown in the specification.

Description

technical field The invention belongs to the field of materials, and in particular relates to a phosphorus-silicon polymer-containing flame-retardant room temperature vulcanized silicone rubber composition and a preparation method thereof. Background technique Due to its special structure, silicone rubber has both the properties of inorganic and organic materials. Compared with ordinary rubber, it has the advantages of non-toxic, odorless, high and low temperature resistance, weather resistance, ozone resistance, and good electrical insulation. It is widely used in aviation, Aerospace, electronics, electrical appliances, construction, automobiles, chemicals and other fields. However, the silicone rubber molecular chain contains a large amount of C and H, and its limiting oxygen index is less than 21%. It is flammable and will continue to burn when exposed to an open flame, which greatly limits its application in fire prevention and leakage prevention. Traditionally, the fl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L83/06C08L83/08C08L85/02C08K3/22C08K3/36C08J3/24

Inventor 张志杰郭胜立谭永霞费华峰高希银谢江谢择民

Owner INST OF CHEM CHINESE ACAD OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com