Welded high-matrix diamond core bit and manufacturing method thereof

A production method and high matrix technology, applied in the direction of drill bits, welding equipment, laser welding equipment, etc., can solve the problems of high tripping frequency of the drill bit, low overall drilling efficiency, low drilling efficiency of the drill bit, etc., and achieve drilling efficiency High, improve the efficiency of drilling engineering and the effect of improving the monthly efficiency of drilling platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

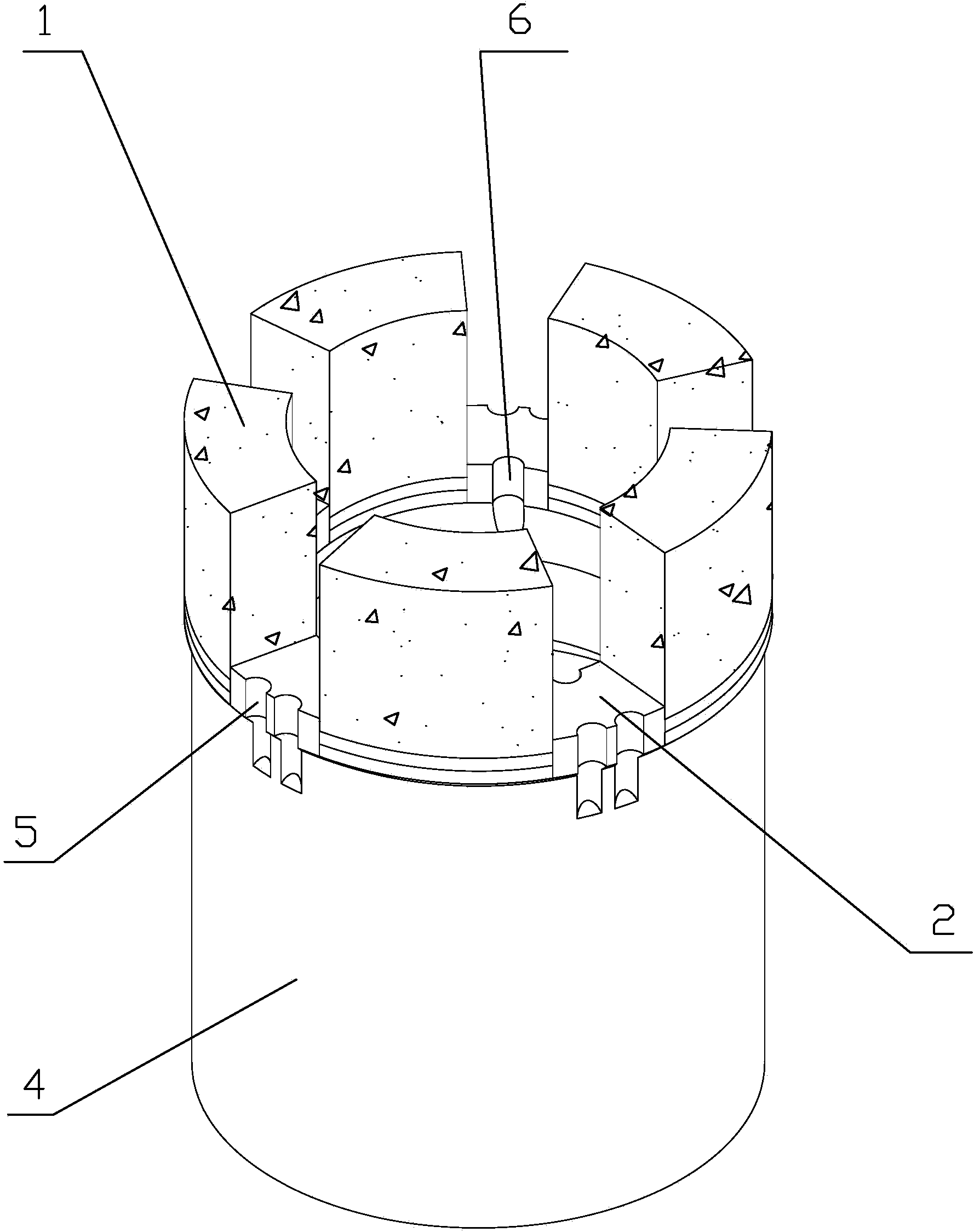

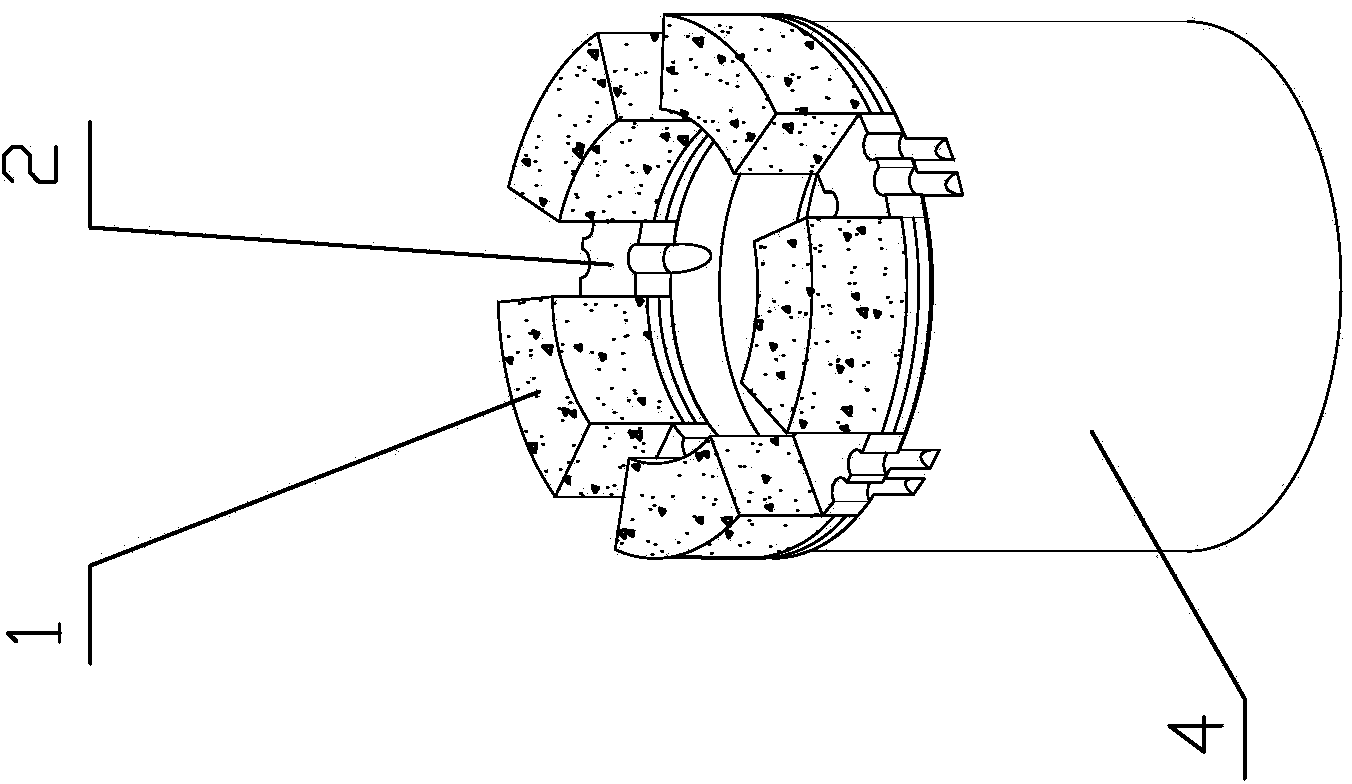

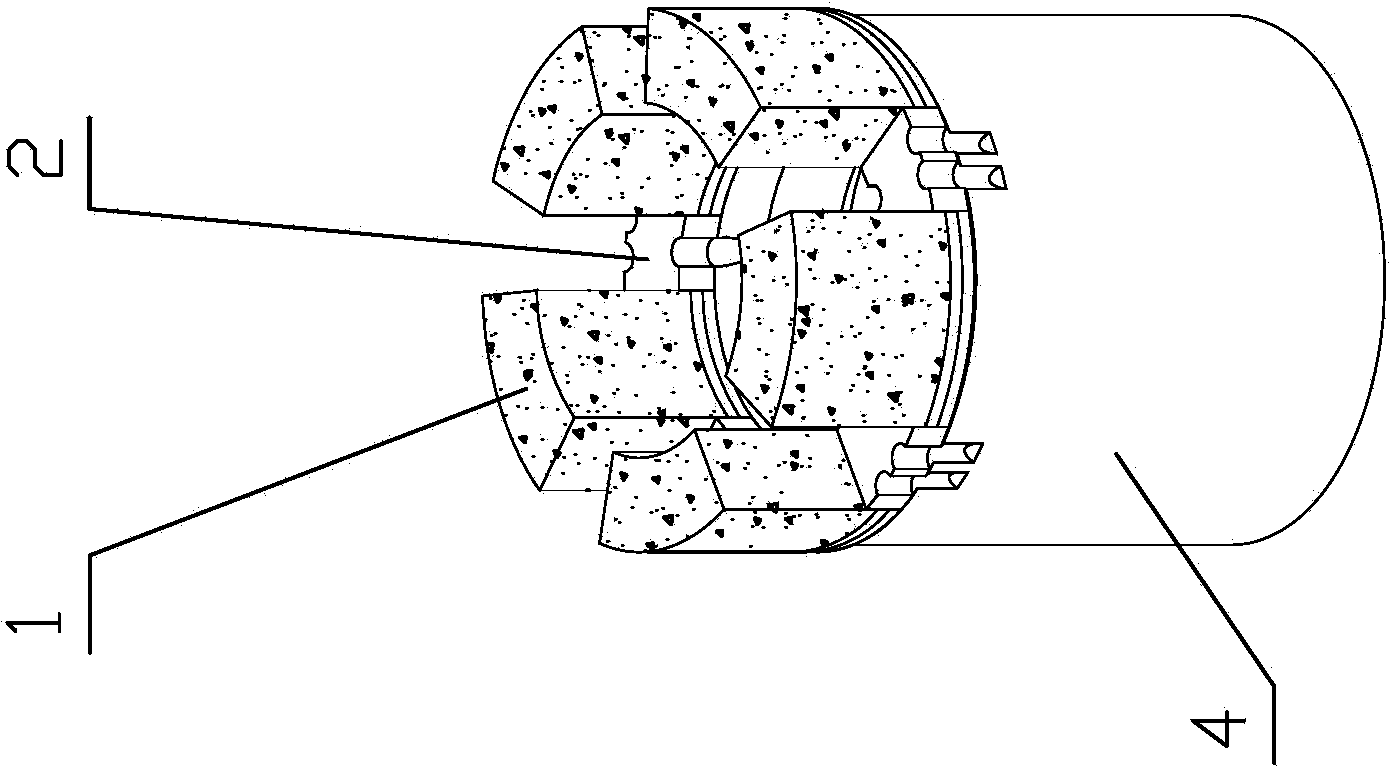

[0033] The technical solution of the present invention will be further described below in conjunction with the embodiments shown in the drawings.

[0034] The welded high matrix geological drill bit of the present invention includes an upper drill tooth crown 3 and a lower steel body 4 that are connected. The drill tooth crown 3 includes a high matrix drill tooth 1 and a nozzle block 2. The high matrix drill The teeth 1 are uniformly distributed on the circumference of the steel body 4, and the nozzle blocks 2 are arranged on the steel body 4 between the adjacent high carcass drill teeth 1 at intervals; the high carcass drill teeth 1 include upper, middle and lower three The parts are working tooth layer 1-1 with rock breaking abrasive particles in the upper part, transition tooth layer 1-2 without abrasive particles in the middle part, welded tooth layer 1-3 without abrasive particles in the lower part, and high matrix drill tooth 1. The total height is 15mm~35mm. According to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com