Method for preparing six-core MgB2 superconducting wire by magnesium diffusion method

A technology of superconducting wire and diffusion method is applied in the field of preparation of 6-core MgB2 superconducting wire, which can solve the problems of incapable of industrialized production, complicated process and high equipment requirements, and achieves enhanced mechanical properties, increased area, and increased densification degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

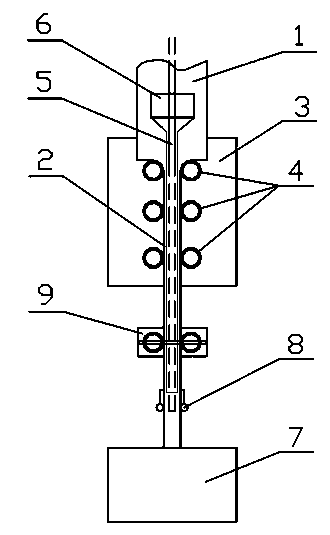

[0029]Step 1: Install a fixed-core magnesium rod 5 with a diameter of 4mm and a purity greater than 99.8% between the pressure rollers 4 on the left and right sides of the coiler 3, and install the upper end of the fixed-core magnesium rod 5 on the discharge of the special long-necked hopper 6 Below the mouth, the lower end of the special long-necked hopper is located 10cm below the welding machine, and the niobium strip 1 with a width of 35mm and a thickness of 1.5mm is sent to the coiler 3 to be rolled into a niobium tube 2, and the lower end of the niobium tube 2 is shaped by a mold Fix the fixed-core magnesium rod at the center of the niobium tube 2, and then fill the hopper 6 with amorphous boron powder with a purity of not less than (greater than or equal to) 99% and nano-SiC powder with a purity of not less than (greater than or equal to) 99.8% Composed of mixed powder, the mixed powder flows into the niobium tube 2, wherein the mixed powder composed of amorphous boron p...

Embodiment 2

[0035] Step 1: Install a fixed-core magnesium rod 5 with a diameter of 5mm and a purity greater than 99.8% between the pressure rollers 4 on the left and right sides of the coiler 3, and install the upper end of the fixed-core magnesium rod 5 on the discharge of the special long-necked hopper 6 Below the mouth, the lower end of the special long-necked hopper is located 15cm below the welding machine, and the niobium strip 1 with a width of 40mm and a thickness of 2mm is sent to the tube coiler 3 to be rolled into a niobium tube 2, and the lower end of the niobium tube 2 is rolled by a shaping abrasive The fixed core magnesium rod is fixed in the center of the niobium tube 2, and then the mixed powder composed of amorphous boron powder with a purity of not less than 99% and nano-SiC powder with a purity of not less than 99.8% is loaded into the hopper 6, and the mixed powder flows into the niobium tube 2 Among them, the mixed powder composed of amorphous boron powder and nano-Si...

Embodiment 3

[0041] Step 1: Install a fixed-core magnesium rod 5 with a diameter of 4.5mm and a purity greater than 99.8% between the pressure rollers 4 on the left and right sides of the coiler 3, and install the upper end of the fixed-core magnesium rod 5 on the outlet of the special long-necked hopper 6 Below the feed port, the lower end of the special long-necked hopper is located 12cm below the welding machine, and the niobium strip 1 with a width of 38mm and a thickness of 1.8mm is sent to the coiler 3 to be rolled into a niobium tube 2, and the lower end of the niobium tube 2 is shaped by grinding Fix the fixed core magnesium rod in the center of the niobium tube 2, and then fill the hopper 6 with a mixed powder composed of amorphous boron powder with a purity of not less than 99% and nano-SiC powder with a purity of not less than 99.8%, and the mixed powder flows into the niobium In the tube 2, the mixed powder composed of amorphous boron powder and nano-SiC powder is configured acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com