Quantum dot, method for manufacturing quantum dot and quantum dot LED device

A technology of LED devices and quantum dots, applied in electrical components, nanotechnology, circuits, etc., can solve the problems of reducing the optical performance and structural defects of quantum dots with core-shell structure, and achieve high electroluminescence efficiency, high spectral purity, and high light Effect of Luminescent Quantum Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

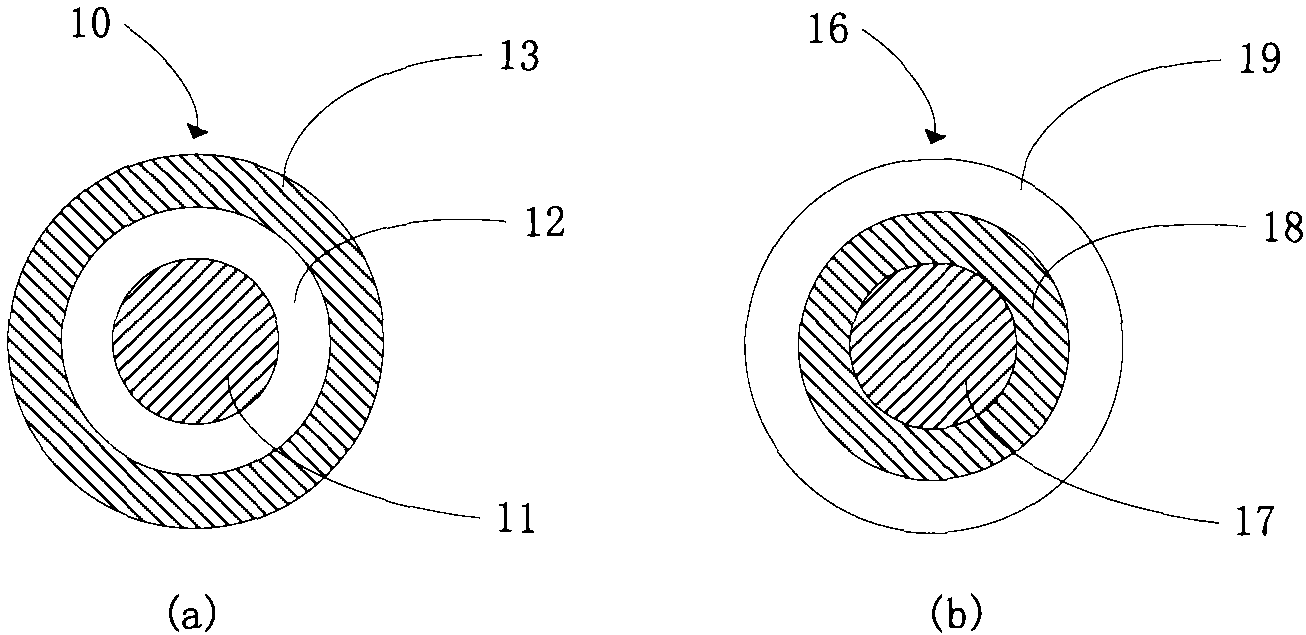

[0049] figure 2 Shown is a schematic diagram of the structure of the quantum dots in this embodiment. like figure 2 As shown in (a), the quantum dot 10 in this embodiment includes: a CdSe core 11, the CdSe core 11 is covered with a first shell 12, and the first shell 12 is covered with a second shell 13 , the first shell layer 12 is an exciton confinement layer, and the second shell layer 13 is a stress compensation layer. Wherein, the stress compensation layer 13 is a ZnCdS layer, and the exciton confinement layer 12 is a ZnS layer.

[0050] like figure 2 Shown in (b), the comparative example quantum dot 16 in the present embodiment comprises: CdSe core 17, and CdSe core 17 is covered with shell layer, and described shell layer is by inside and outside including: ZnS layer 18 and ZnCdS layer 19.

[0051] Image 6 It is the X-ray diffraction pattern of the quantum dot crystal structure in this embodiment. The crystal structure of quantum dots was measured by Bruker D...

Embodiment 2

[0061] Figure 5 It is a flowchart of the quantum dot preparation method in the embodiment of the present invention. as the picture shows:

[0062] Step S1: making CdSe core 11 with Cd precursor and Se precursor, and the CdSe core 11 is formed in the first solution.

[0063] Specifically, the stearylamine-coated quantum dot CdSe core 11 is prepared by using a general hot injection method from CdO and Se as precursors. The CdSe nuclear quantum dot has a first exciton absorption peak of 528nm, which is precipitated by adding methanol, separated and then Centrifuge to remove by-products and unreacted precursors. Quantum dot CdSe cores are dispersed in hexane to form a first solution for further synthesis.

[0064] Step S2: growing a first shell 12 outside the CdSe core 11, and the first shell 11 is formed in the second solution.

[0065] Specifically, CdSe / ZnS and CdSe / ZnS were synthesized by the successive ion layer adsorption and reaction (Successiveion Layer Adsorption and...

Embodiment 3

[0069] Figure 4 It is a schematic diagram of the structure of QD-LED in this embodiment (please supplement the accompanying drawings). As shown, the LEDs in this embodiment include:

[0070] Substrate 41, such as glass 43 with ITO film layer 42, ITO is used as anode;

[0071] The hole injection layer 44 on the substrate is, for example, PEDOT:PSS with a thickness of 40 nm;

[0072] The hole transport layer 45 above the hole injection layer 44 is, for example, poly-TPD with a thickness of 40 nm;

[0073] The quantum dot luminescent layer 46 on the 45 of the hole transport layer, the quantum dot luminescent layer 46 includes: a CdSe core, a first shell layer covering the CdSe core, and a second shell layer covering the first shell layer , wherein, the first shell layer is an exciton confinement layer, and the second shell layer is a stress compensation layer; in this embodiment, preferably, the stress compensation layer of the quantum dots is a ZnCdS layer, and the quantum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com