Star-shaped ground body of nanometer conductive anticorrosion coating

A nano-conductive and anti-corrosion coating technology, applied in the direction of connecting contact materials, etc., can solve the problems of patent application of star-shaped grounding body without nano anti-corrosion coating, and achieve good electrical conductivity and anti-corrosion ability, long service time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples illustrate the present invention, but these examples should not be construed as limiting the present invention.

[0025] Take the star-shaped steel grounding body with nano-carbon conductive coating as an example:

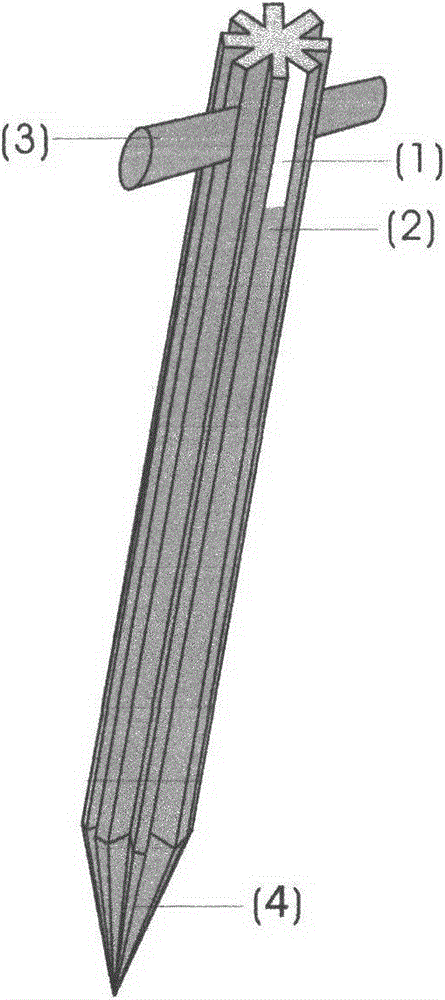

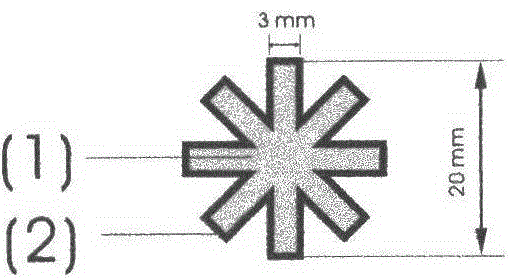

[0026] 1. Preparation of the star-shaped steel grounding body: Open the mold at one time, and use the casting method to form a star-shaped steel grounding rod with a diameter of 2 cm and a length of 200 cm. One end of the steel rod is tapered, which is convenient for hitting and inserting into the ground.

[0027] 2. Preparation of nano-conductive anti-corrosion coating: nano-conductive anti-corrosion coating mainly consists of nano-carbon (5-60%), epoxy urushiol resin (5-60%) and organic solvent (xylene and ethyl acetate 1: 1 , 5-60%) composition. Nano carbon powder is used as coating raw material by purchasing conductive carbon black powder on the market. Mix nano-carbon powder with organic solvents and other ball mills, and form n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com