Automatic heating device for special polyethylene wax for marking of road

A polyethylene wax, automatic heating technology, applied in mixers with rotary stirring devices, heat treatment, mixers, etc., can solve the problems of lack of solutions, inability to form temperature gradients, etc., saving manpower, energy, and easy heating effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

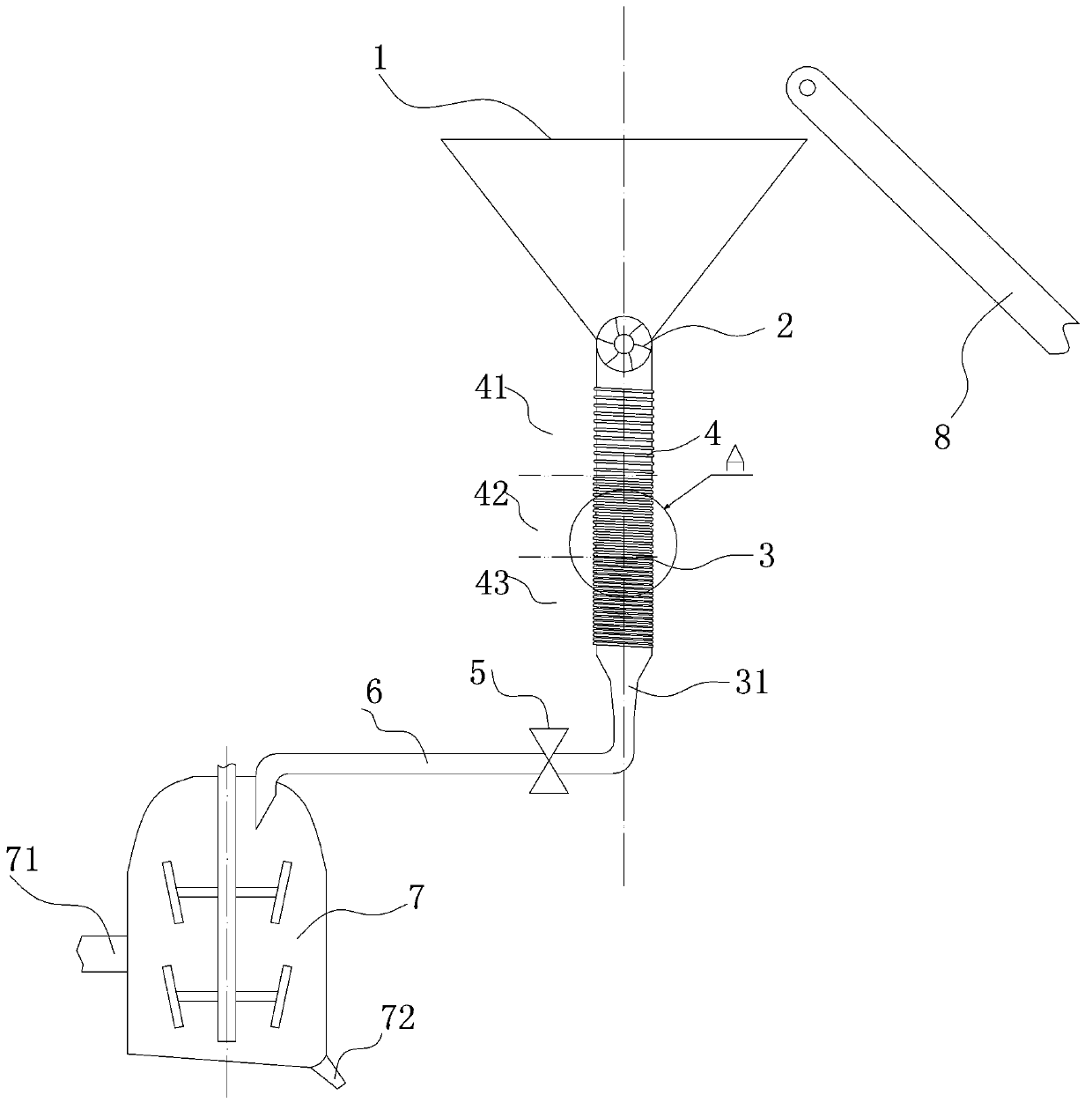

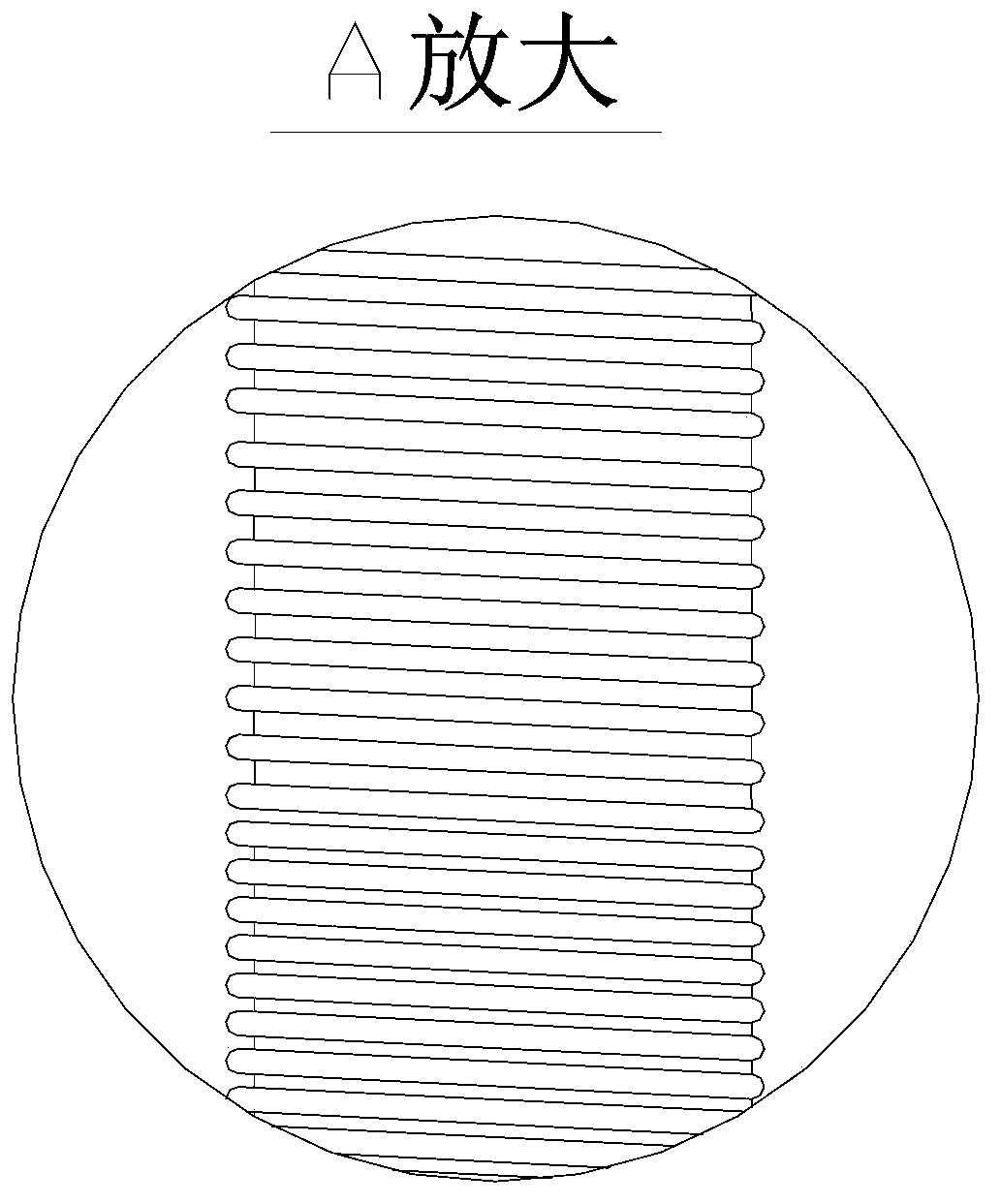

[0017] Embodiment one: if figure 1 As shown, an automatic heating device for polyethylene wax dedicated to road markings, including a conveyor belt 8, a feeding hopper 1, a feeder 2, an iron heating pipeline 3, an electromagnetic coil 4 and a fluid delivery pipe 6; The outlet of the conveyor belt 8 is connected to the upper mouth of the feeding hopper 1, and the lower mouth of the feeding hopper 1 is connected to the feed inlet of the heating pipeline 3, and the feeder 2 can be a star feeding The device is arranged at the feed inlet of the heating pipeline 1; the electromagnetic coil 4 is wound on the outer surface of the heating pipeline 3; the electromagnetic coil 4 is provided with at least two sets of coil groups with increasing temperature. For example: the electromagnetic coil 4 is provided with three sets of coil groups with increasing temperature from top to bottom, which are respectively coil group one 41, coil group two 42 and coil group three 43, and they are respec...

Embodiment 2

[0018] Embodiment 2: The difference from Embodiment 1 is that the heating pipeline is divided into four sections, which are respectively the second heating section 1, the second heating section 2, the second heating section 3 and the second heating section 4; The electromagnetic coil 4 is provided with four sets of coil groups with increasing temperature from top to bottom, which are respectively the second coil group one, the second coil group two, the second coil group three and the second coil group four, and they are respectively wound on the On the second heating section one, the second heating section two, the second heating section three and the second heating section four of the iron heating pipeline 3; the second heating section one, the second heating section two, the second heating section The temperatures of section three and second heating section four are respectively controlled at 80-90 degrees, 90-100 degrees, 120-130 degrees and 130-150 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidification point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com