Mixed-flowair-flotationwater purification method

A floating water purification and air flow technology, which is applied in the field of mixed flow air flotation water purification to achieve the effect of improving water purification effect, increasing effective adhesion efficiency, and improving the ability to resist the risk of water quality changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

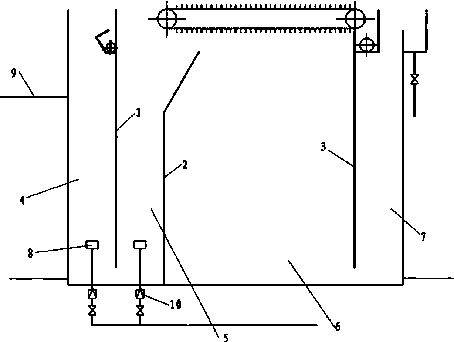

Image

Examples

Embodiment 1

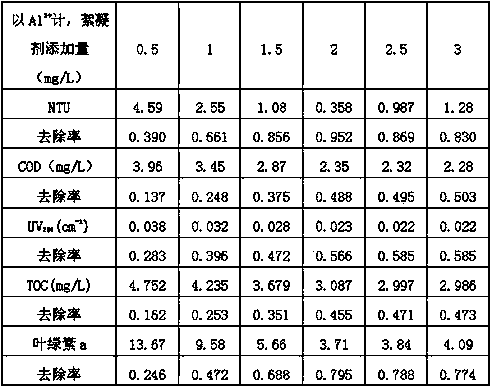

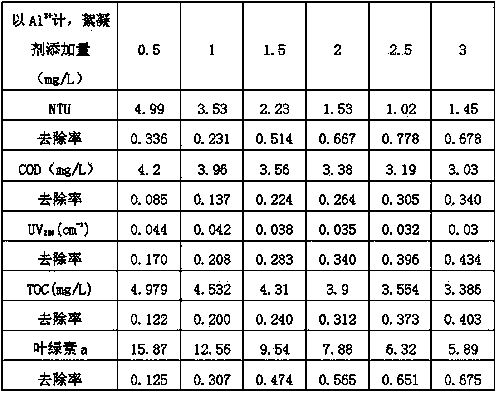

[0053] Take the Yellow River Diversion Water in a certain area as an example, the turbidity of raw water is 7.52NTU, COD Mn , UV 254 , TOC were 4.59mg / L, 0.053, 5.668mg / L, chlorophyll a was 18.13mg / L, algae count was pH 7.93~8.44, water temperature was 10.8~11.6℃.

[0054] The flocculant used in the flocculation stage is PAFC (polyaluminum ferric chloride), and the G value of the primary flocculation stage is 65S -1 , the G value of the second flocculation stage is 40S -1 , and stirred for 10 min to obtain water to be purified.

[0055] (1) After the flocculation stage, the water to be purified with flocculant added enters the collision contact chamber, and the flow rate of the incoming water is 15mm / s, and the microbubbles released by the dissolved air releaser installed at the bottom of the collision contact chamber flow countercurrently with the water to be purified , the dissolved air pressure is 0.35Mpa, the distribution ratio of dissolved air and water in the collisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com