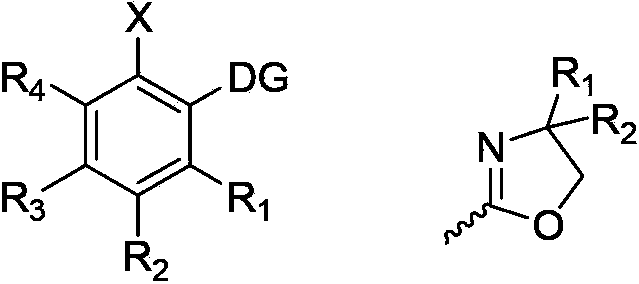

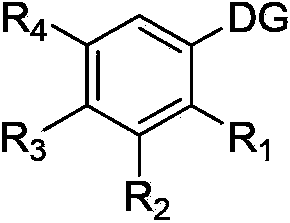

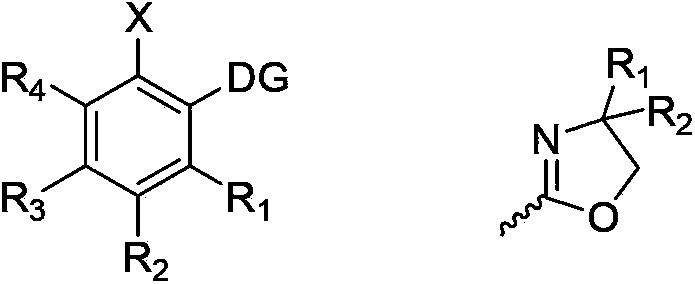

Halogenated aromatic ring compound and preparation method thereof

A technology of halogenated aromatic rings and compounds, which is applied in the preparation of carbon-based compounds, organic compounds, halogenated hydrocarbons, etc., to achieve the effects of simplifying the synthesis reaction route, simplifying the synthesis steps, and improving drug compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, preparation formula 1 compound

[0033]

[0034] Formula 1

[0035] 90mg of ethyl benzoate, 40mg of N-chlorosuccinimide, 3.4mg of Pd(OAc) 2 Add 160mg of selective fluorine reagent to a sealed tube, add 1,2-dichloroethane to dissolve; add 53uL trifluoromethanesulfonic acid under stirring, seal it, and stir at 90°C for 3h. In this reaction system, ethyl benzoate, N-chlorosuccinimide, Pd(OAc) 2 , The molar ratio of trifluoromethanesulfonic acid and selective fluorine reagent is 2:1:0.05:2.0:1.5. After the reaction was completed, 1,2-dichloroethane was added to quench the reaction, and the remaining acid and salt were washed away with saturated aqueous sodium bicarbonate solution, and extracted twice with 1,2-dichloromethane. The extracts were combined, dried with anhydrous sodium sulfate, and the solvent was removed by rotary evaporation. The residue was separated and purified by silica gel chromatography (n-hexane:ether (volume ratio 200:1)) to obtain ...

Embodiment 2

[0039] Embodiment 2, preparation formula 2 compound

[0040]

[0041] Formula 2

[0042] 60mg of ethyl benzoate, 36mg of N-bromosuccinimide, 2.3mg of Pd(OAc) 2 Add 106mg of selective fluorine reagent to a sealed tube, add 1,2-dichloroethane, dissolve; add 35uL trifluoromethanesulfonic acid while stirring, seal, and stir at 90°C for 4h. In this reaction system, ethyl benzoate, N-chlorosuccinimide, Pd(OAc) 2 , The molar ratio of trifluoromethanesulfonic acid and selective fluorine reagent is 2:1:0.05:2.0:1.5. After the reaction was completed, 1,2-dichloroethane was added to quench the reaction, and the remaining acid and salt were washed away with saturated aqueous sodium bicarbonate solution, and extracted twice with 1,2-dichloromethane. The extracts were combined, dried over anhydrous sodium sulfate, and the solvent was removed by rotary evaporation. The residue was separated and purified by silica gel chromatography (n-hexane:ether (volume ratio 200:1)) to obtain 35 mg of...

Embodiment 3

[0046] Embodiment 3, preparation formula 3 compound

[0047]

[0048] Formula 3

[0049] 88mg of ethyl p-toluate, 40mg of N-chlorosuccinimide, 3.4mg of Pd(OAc) 2 Add 108mg of sodium persulfate to a sealed tube, add 1,2-dichloroethane to dissolve; add 40uL trifluoromethanesulfonic acid while stirring, seal it, and stir at 70°C for 4h. In this reaction system, ethyl p-toluate, N-chlorosuccinimide, Pd(OAc) 2 , The molar ratio of trifluoromethanesulfonic acid and sodium persulfate is 2:1:0.05:1.5:1.5. After the reaction was completed, 1,2-dichloroethane was added to quench the reaction, and the remaining acid and salt were washed away with saturated aqueous sodium bicarbonate solution, and extracted twice with 1,2-dichloromethane. The extracts were combined, dried with anhydrous sodium sulfate, and the solvent was removed by rotary evaporation. The residue was separated and purified by silica gel chromatography (n-hexane:ether (volume ratio 200:1)) to obtain 40 mg of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com