Preparation technology for natural vitamin E

A natural vitamin and preparation technology, applied in the direction of organic chemistry, can solve the problems of low yield, excessive use of organic solvents, and many purification steps, and achieve high yield, qualified optical rotation, and more transparent color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

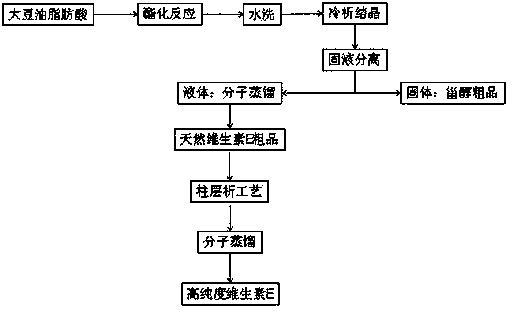

Image

Examples

Embodiment 1

[0024] Soybean oil fatty acid 1Kg is put into three-necked flask, 95 oC After vacuum degassing in a water bath, the material was cooled to 65 oC Thereafter, concentrated sulfuric acid (20 ml) was added with stirring, and methanol (340 ml) was added. The water bath was added and the temperature was raised to 65 oC , control the temperature in the kettle at 64-78 degrees and stir and reflux for 60min. After reflux, add the material to 90 oC The above hot water 150ml, wash with water, discard the water layer, put the oil layer in 5 oC Cold analysis in the environment, crystallization of phytosterols. Put the material into the filter press tank for press filtration to obtain oily liquid. oily liquid at 120 oC , Distilled at a pressure of 1pa. The residual component after distillation is natural vitamin E crude product with a purity of 48%.

[0025] The above natural vitamin E crude product is carried out column chromatography using a macroporous nonpolar resin, at a f...

Embodiment 2

[0027] Soybean oil fatty acid 1Kg is put into three-necked flask, 95 oC After vacuum degassing in a water bath, the material was cooled to 65 oC Thereafter, concentrated sulfuric acid (20 ml) was added with stirring, and methanol (240 ml) was added. The water bath was added and the temperature was raised to 65 oC , control the temperature in the kettle to 64-78 oC Stir and reflux for 60min. After reflux, add the material to 90 oC The above hot water 220ml, wash with water, discard the water layer, put the oil layer in 10 oC Cold analysis in the environment, crystallization of phytosterols. Put the material into the filter press tank for press filtration to obtain oily liquid. oily liquid at 130 oC , Distilled at a pressure of 5pa. The residual component after distillation is natural vitamin E crude product with a purity of 40%.

[0028] The above-mentioned natural vitamin E crude product is carried out column chromatography using a macroporous non-polar resin, a...

Embodiment 3

[0030] Soybean oil fatty acid 1Kg is put into three-necked flask, 95 oC After vacuum degassing in a water bath, the material was cooled to 65 oC Next, add concentrated sulfuric acid (20ml) and ethanol (440ml) while stirring. The water bath was added and the temperature was raised to 65 oC , control the temperature in the kettle to 64-78 oC Stir and reflux for 60min. After reflux, add the material to 90 oC Wash with 300ml of the above hot water, discard the water layer, place the oil layer in a 10-degree environment for cold analysis, and crystallize phytosterols. Put the material into the filter press tank for press filtration to obtain oily liquid. oily liquid at 120 oC , Distilled at a pressure of 10pa. The residual component after distillation is the natural vitamin E crude product with a purity of 52%.

[0031] The above-mentioned natural vitamin E crude product is carried out column chromatography using non-polar resin, at a flow rate of 5ml / min, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com