Lignosulfonate modified sulfamic acid series high-efficiency water reducer and preparation method thereof

A technology of lignosulfonate and high-efficiency water reducer, which is applied in the field of concrete admixtures, can solve the problems of small concrete slump, insufficient dispersion of cement particles, and sensitive dosage, so as to solve the phenomenon of segregation bleeding and improve The effect of protecting the collapse and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A preparation method of lignosulfonate modified sulfamic acid series high-efficiency water reducer, which comprises the following steps:

[0013] 1) Dissolution: Add 110g of water into the reactor, then add 75g of sodium sulfanilate and 60g of phenol respectively, heat up the reactor to 70°C, turn on the stirrer and stir for 30 minutes;

[0014] 2) Addition: Slowly add 30% sodium hydroxide solution into the reactor to adjust the pH value to 9;

[0015] 3) Polycondensation: After heating the reactor to 90°C, add 80g of formaldehyde dropwise and keep the temperature constant for 5 hours;

[0016] 4) Copolymerization: The temperature of the reactor is raised to 95°C, 30g of lignosulfonate and 10g of acrylic acid are added, and the reaction is continued at a constant temperature of 95°C for 2 hours;

[0017] 5) Cool down to room temperature and replenish 110g of water to obtain a lignosulfonate-modified sulfamic acid-based high-efficiency water reducer.

Embodiment 2~4

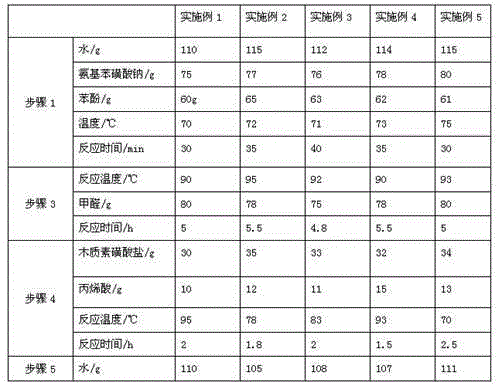

[0019] Adopting the same preparation method as Example 1, the difference is that the addition amount, reaction time, reaction temperature, and pH value of each component different in each step listed in Table 1 are used to replace the corresponding numerical values adopted in Example 1 .

[0020] Table 1

[0021]

[0022] The performance data of the concrete after the concrete modification admixture modification that makes with embodiment 1-5 is as shown in table 2:

[0023] Table 2

[0024]

[0025] As can be seen from the data in Table 2, the concrete modified by the concrete modified admixture obtained in Examples 1-5 is consistent with the test standard of the national standard "Concrete Admixture" and the unmodified sulfamic acid series water reducer In comparison, the water reducing rate is high, the bleeding rate is low, the air content is low, the 28d shrinkage ratio is low, and the concrete strength is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com