Tough nylon and preparation method thereof

A nylon and toughness technology, applied in the field of tough nylon and its preparation, to achieve the effects of high mechanical strength, improved impact resistance and moderate price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

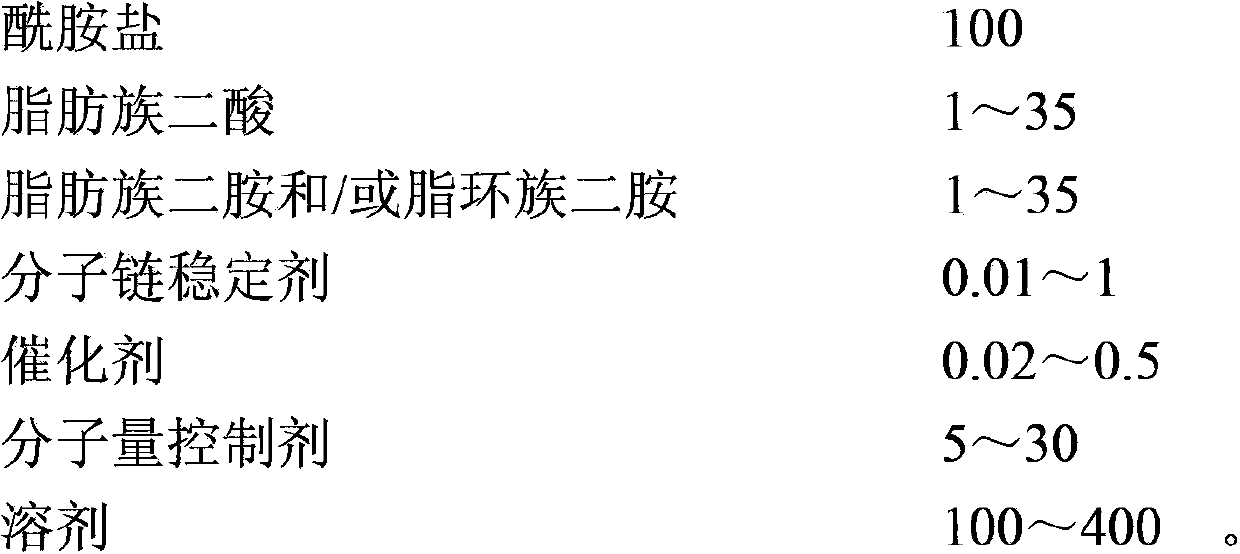

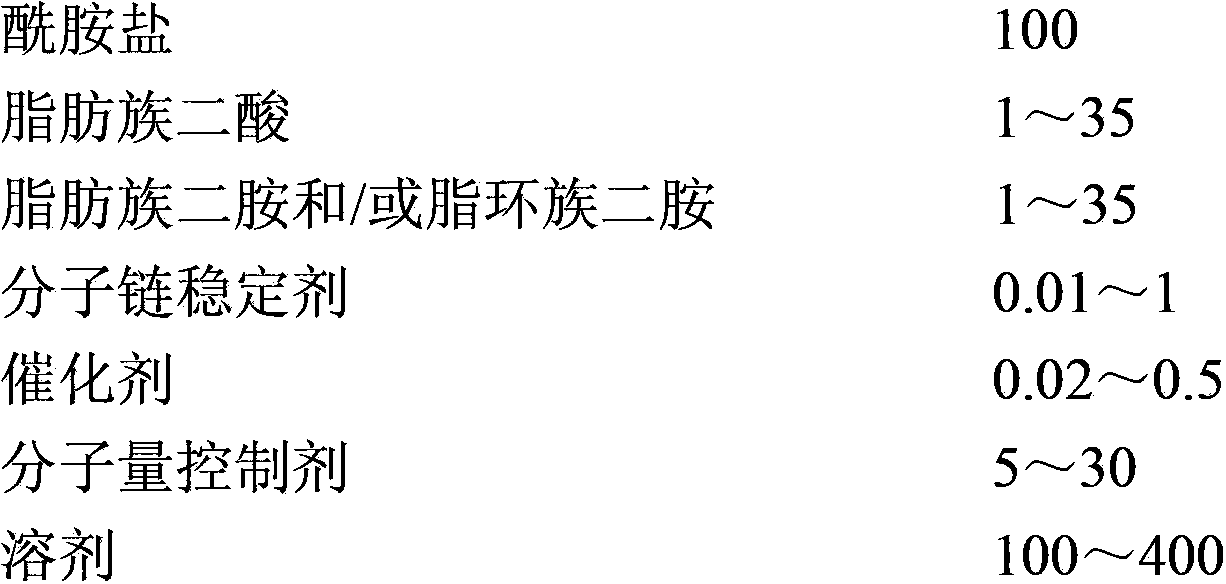

Method used

Image

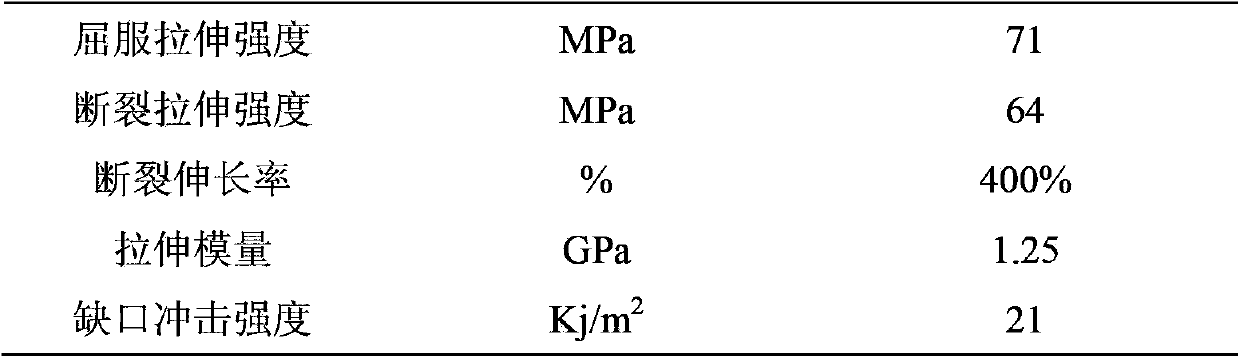

Examples

Embodiment 1

[0029] (1) Add 1000g of deionized water into the reaction kettle, turn on the stirrer, and under the stirring bar, add 300g of nylon 66 salt, 15g of adipic acid as a molecular weight control agent, and 75g of dodecanedipic acid as an aliphatic diacid Add acid and 70g of 4,4'-diamino-dicyclohexylmethane as an alicyclic diamine into deionized water and stir to mix evenly, then add 0.5g of benzoic acid and 0.1g of hypophosphorous acid into the reaction kettle, continue Stir until all the above ingredients are mixed evenly;

[0030] (2) Close the reaction kettle in step (1), fill the reaction kettle with nitrogen and vacuumize 3 to 5 times to discharge the air in the reaction kettle; then fill the reaction kettle with nitrogen to make the initial pressure in the reaction kettle Maintain at 0.2MPa;

[0031] (3) Turn on the heating device, and uniformly raise the temperature of the reactor in step (2) from room temperature to 180°C within 90 minutes, and keep it warm for 30 minutes...

Embodiment 2

[0036] (1) Add 1000g of deionized water into the reaction kettle, turn on the stirrer, and under the stirring bar, add 300g of nylon 66 salt, 20g of adipic acid as a molecular weight control agent, and 18g of dodecane as an aliphatic diacid Add acid and 16g of 4,4'-diamino-dicyclohexylmethane as an alicyclic diamine into deionized water and stir to mix evenly, then add 3g of benzoic acid and 1.5g of hypophosphorous acid into the reaction kettle and continue stirring , until all the above raw materials are mixed evenly;

[0037] (2) Close the reaction kettle in step (1), fill the reaction kettle with nitrogen and vacuumize 3 to 5 times to discharge the air in the reaction kettle; then fill the reaction kettle with nitrogen to make the initial pressure in the reaction kettle Maintain at 0.5MPa;

[0038](3) Turn on the heating device, and uniformly raise the temperature of the reactor in step (2) from room temperature to 220°C within 120 minutes, and keep it warm for 60 minutes,...

Embodiment 3

[0043] (1) Add 1000g of deionized water into the reaction kettle, turn on the stirrer, and under the stirring bar, add 300g of nylon 66 salt, 22g of adipic acid as a molecular weight control agent, and 100g of dodecanedipic acid as an aliphatic diacid acid and 89g of 3,3'-dimethyl-4,4'-diamino-dicyclohexylmethane as an alicyclic diamine were added to deionized water and stirred evenly, then 0.03g of benzene was added to the reaction kettle Formic acid and 0.06g hypophosphorous acid, continue stirring until all the above raw materials are mixed evenly;

[0044] (2) Close the reaction kettle in step (1), fill the reaction kettle with nitrogen and vacuumize 3 to 5 times to discharge the air in the reaction kettle; then fill the reaction kettle with nitrogen to make the initial pressure in the reaction kettle Maintain at 0.5MPa;

[0045] (3) Turn on the heating device, and uniformly raise the temperature of the reactor in step (2) from room temperature to 200°C within 100 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com