A precision metering ceramic plunger injection pump

A ceramic plunger and liquid injection pump technology, applied in the field of liquid injection pumps, can solve the problems of impurity generation and short life, and achieve the effects of prolonging life, reducing requirements, and reducing axial clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

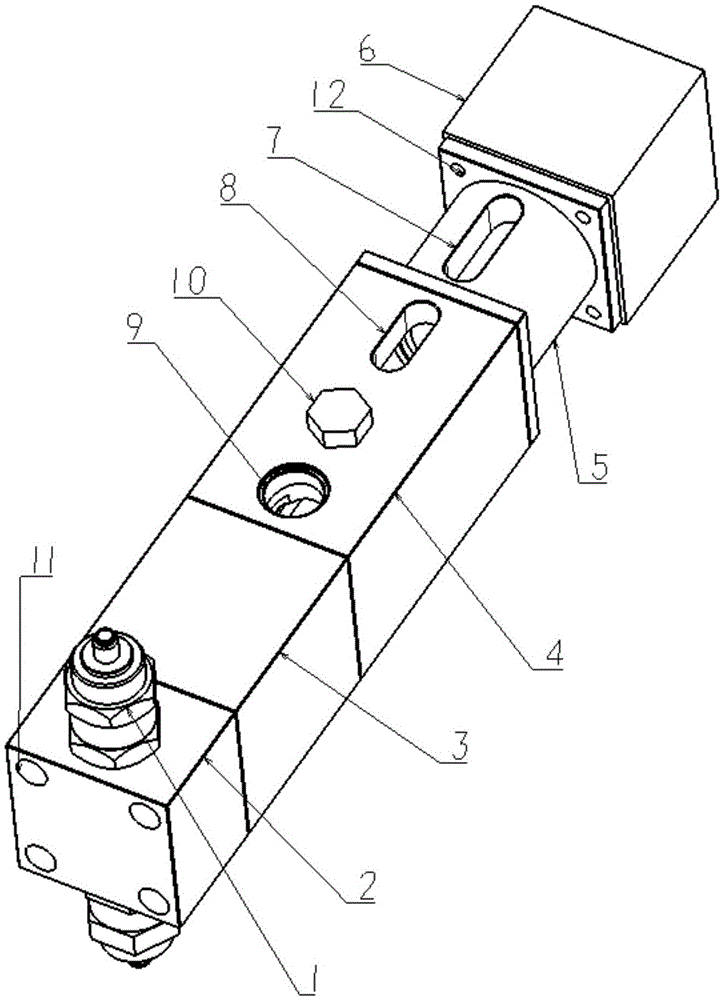

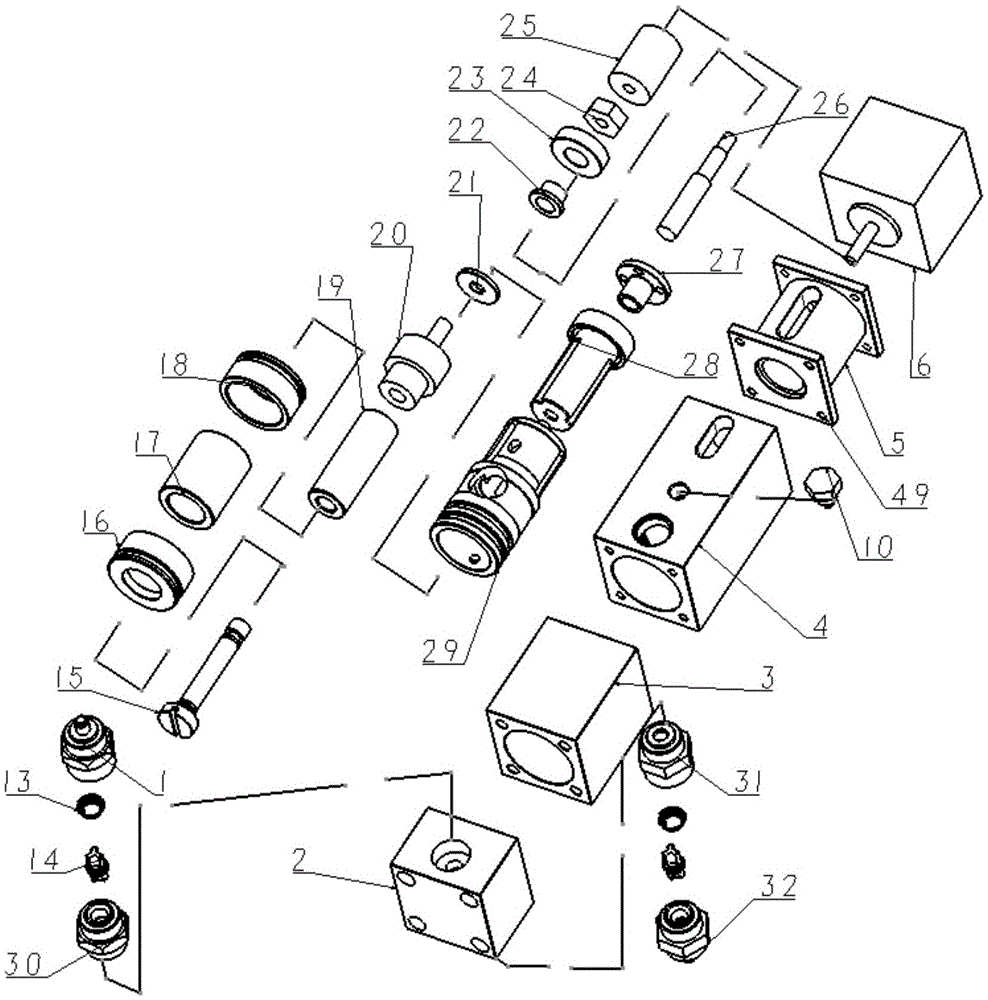

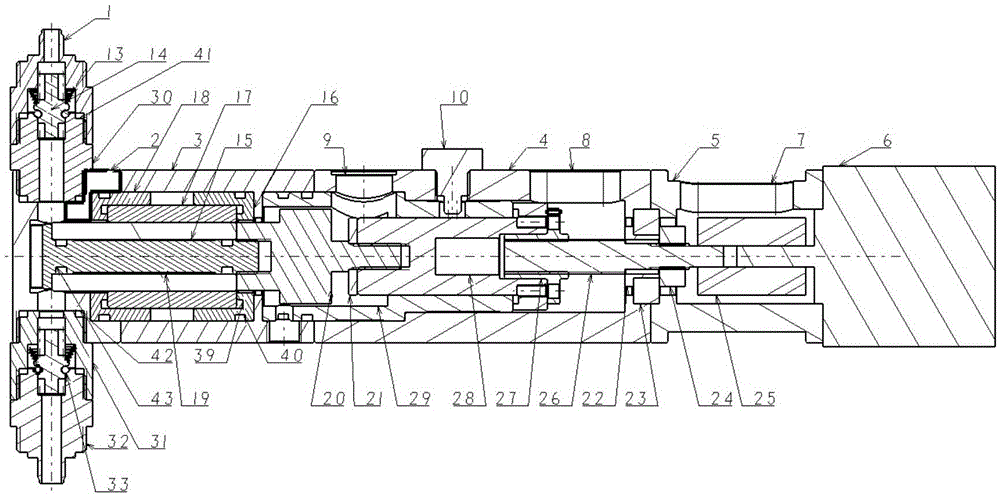

[0028] A precision metering ceramic plunger injection pump of the present invention will be described in detail below with reference to the accompanying drawings.

[0029] Such as figure 1 , figure 2 , image 3 As shown, a precision metering ceramic plunger injection pump of the present invention includes a pump head 2, two one-way valves, a pump body, a driving mechanism and a control drive unit. The one-way valve passes through the upper valve seat and the lower valve seat. The thread on the valve cover is connected to the threaded hole in the pump head 2, and the pump head 2 is fastened to the drive shell 4 through the four through holes and the pump casing 3 through the inner hexagonal bolt; the motor base 5 is passed through the inner hexagonal bolt Fasten to the drive housing 4 through four through holes, and the drive motor 6 is fastened to the motor base 5 through four through holes through hexagon socket bolts; one end of the plunger core 15 in the pump body is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com