Novel optical fiber touch sensor array and manufacturing method thereof

An array sensor, tactile sensor technology, applied in instruments, force measurement, force/torque/work measuring instrument by measuring the change of optical properties of materials under stress, etc., can solve the problem of unreliable contact, decreased sensitivity, non- Large sensitive area and other problems, to achieve the effect of improving sensitivity, accurate positioning, and realizing multiplexing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in detail below in conjunction with accompanying drawing:

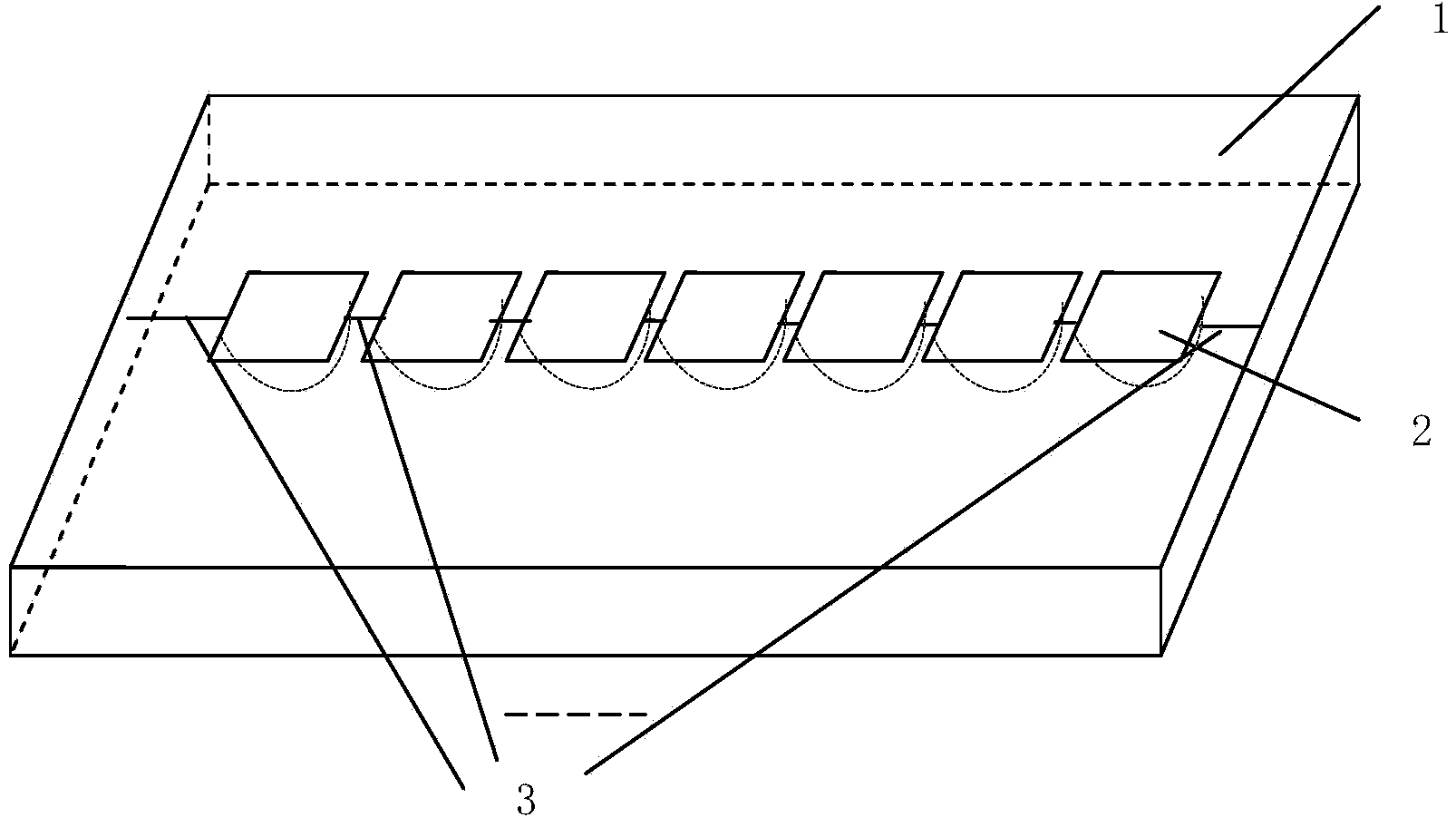

[0050] figure 1 It is a horizontal tandem model mold 1, which includes a polymethyl methacrylate (PMMA) material plate, on which there are a horizontal tandem model mold central groove 2 and an optical fiber grating etching groove 3.

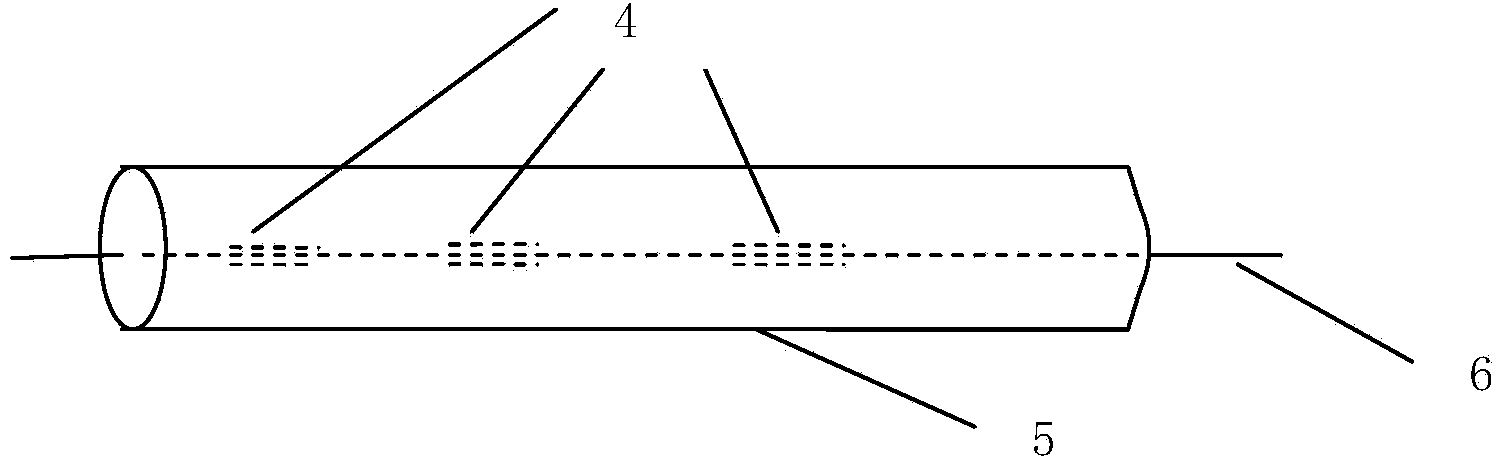

[0051] figure 2 Optical fiber grating diagram, including the fiber core 6 engraved with grating, cladding and coating layer on the outside, fiber grating 4 inside,

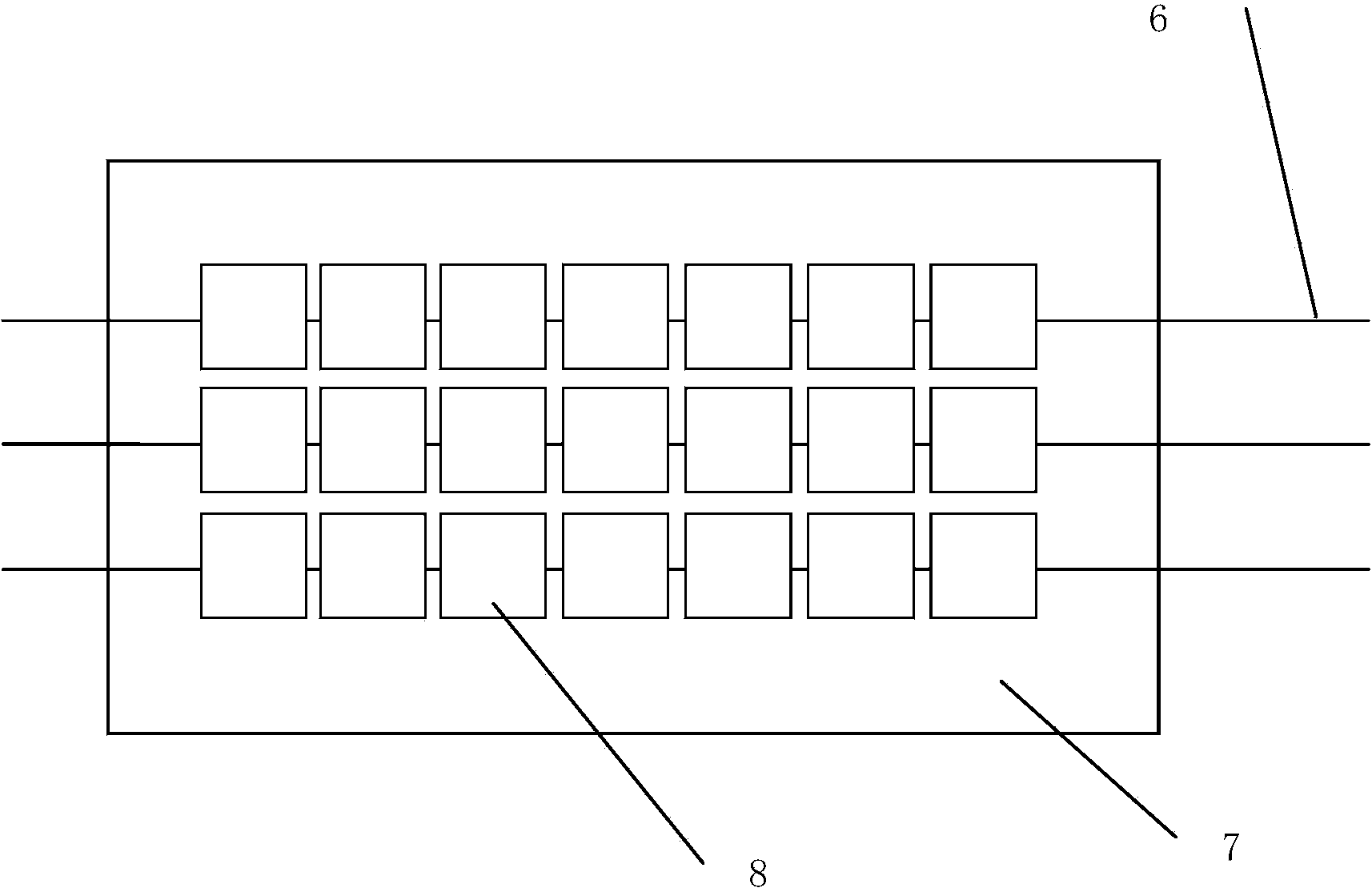

[0052] The overall structure diagram is as follows Figure 3-6 As shown, a film 7 is included, and an array composed of several row sensors is set on the film 7, and the row sensor includes n elastic devices arranged in a row and a fiber grating 4 sensor passing through the elastic device; and a The elastic device and a section of fiber grating form a single fiber optic tactile sensing unit 8; gaps are left between the row sensors, leaving space for the sensors to stretch when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com