Rotation type cavitation erosion and erosive wear synergistic testing apparatus

A technology of synergy and test equipment, which is applied in the direction of testing wear resistance, sustainable manufacturing/processing, climate sustainability, etc. It can solve the problems of long time for testing and setting up equipment, few research reports, and failure to reveal the mechanism of valve damage. , to achieve the effect of easy promotion, simple structure and optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

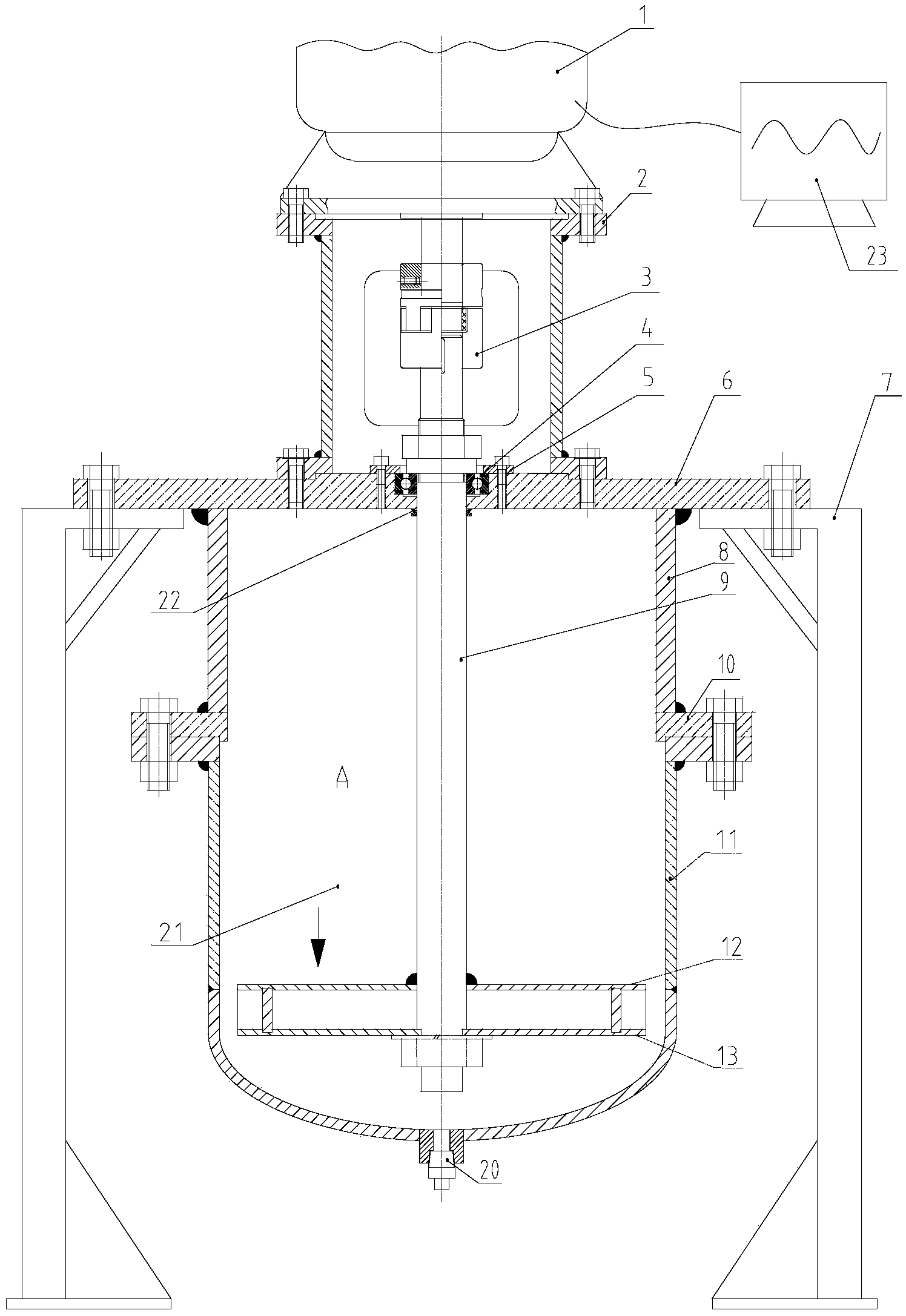

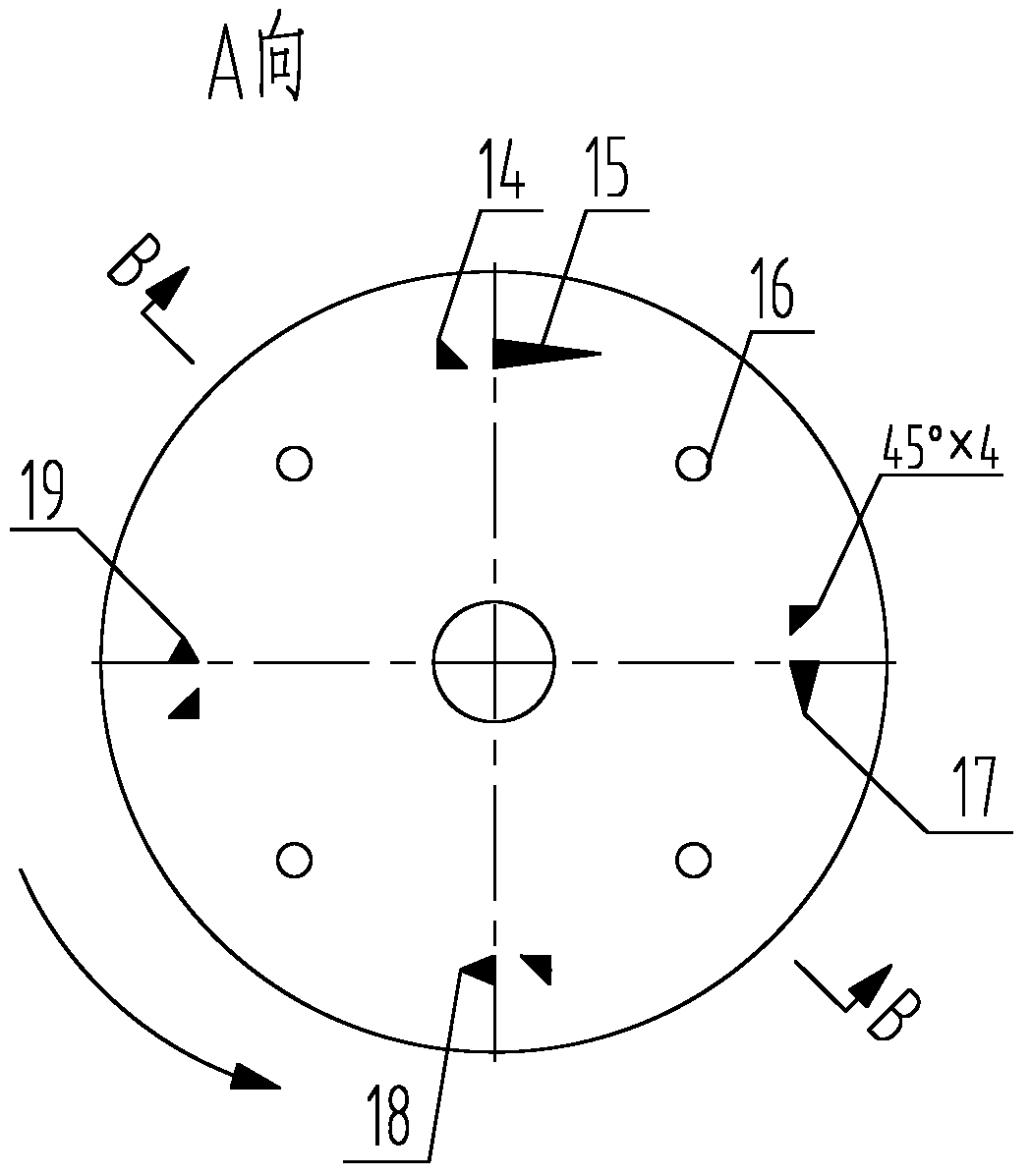

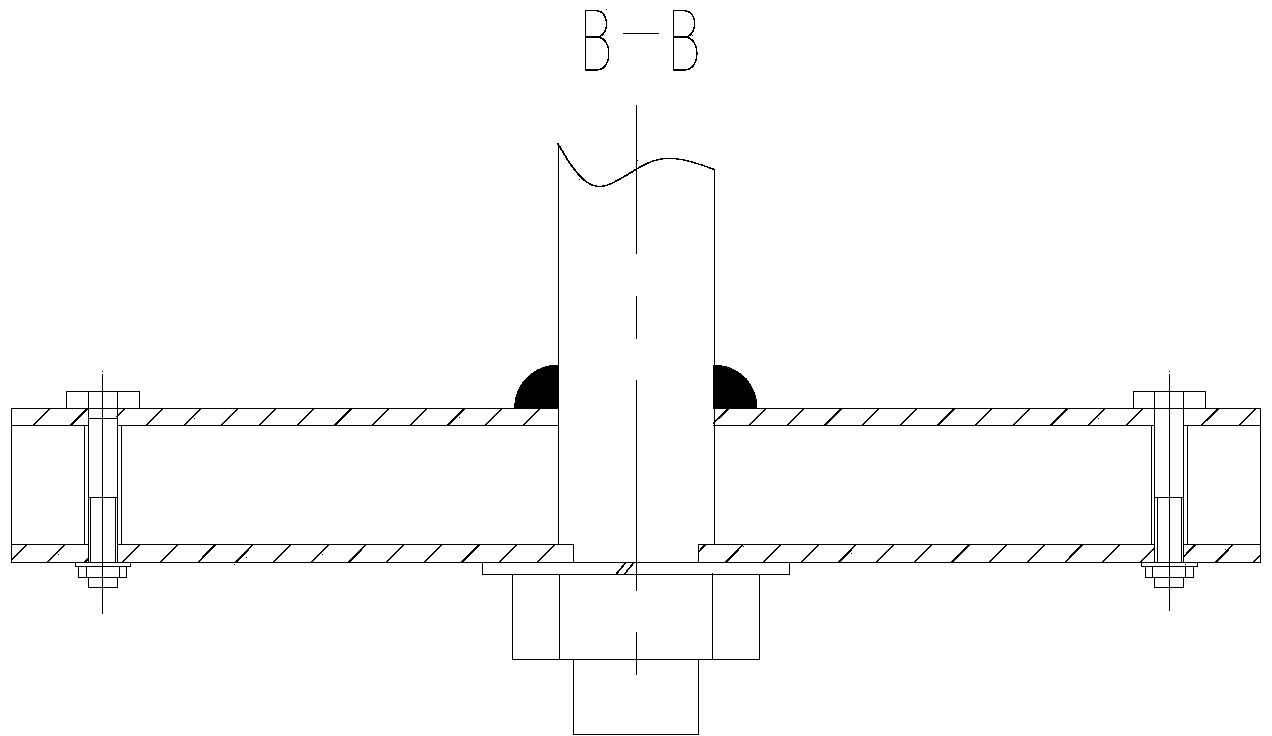

[0025] Such as figure 1 As shown, the liquid-solid two-phase flow wear test device is installed. At the beginning of the experiment, the slurry tank 11 is placed on the forklift, and the prepared fluid medium 21 of a certain concentration, such as coal-water slurry, oil-coal slurry or water mortar etc., pour in the slurry tank 11, and the liquid level has not passed the upper cover plate 12 of the turntable by about 20cm. According to the experimental plan, select four test pieces 14 that have been numbered, wipe the surface clean with alcohol, weigh them five times with an electronic balance, record the original weight, and calculate the average value Insert the test piece 14 and the cavitation inducers 15, 17, 18 and 19 into the grooves of the upper cover plate 12 of the turntable, then install the lower cover plate 13 of the turntable, and fasten the upper cover plate 12 of the turntable with four evenly distributed bolts 16 and the lower cover plate 13 of the turntable; ...

Embodiment 2

[0031] Like Example 1, only the oil-coal slurry, water-coal slurry or water mortar used in the fluid medium 21 in Example 1 is changed to clear water medium, and the cavitation inducers 15, 17, 18 and 19 at different angles can be installed. Cavitation weight loss test.

[0032] When testing in different experimental working conditions, the speed r of the variable frequency motor 1, the angle θ of the specimen 14, the cavitation time t, the density ρ of the liquid, and the cavitation number σ can be changed respectively, so as to realize the cavitation inducer 15, The cavitation weight loss rate test of the fluid medium 21 under the induction of 17, 18 and 19, so as to establish the functional relationship between different influencing factors and the cavitation weight loss rate, that is, the weight loss rate is expressed as:

[0033] ϵ 2 = k · f ( r , ...

Embodiment 3

[0035] Like Example 1, only the cavitation inducers 15, 17, 18 and 19 in Example 1 are removed, and the fluid medium 21 still uses oil-coal slurry, water-coal slurry or water mortar to carry out the erosion of the test piece 14 wear test.

[0036] When testing in different experimental conditions, the speed r of the variable frequency motor 1, the angle θ of the specimen 14 and the wear time t, the concentration w of the fluid medium 21, the density ρ of the liquid, the shape factor δ of solid particles, and the Particle size d. Thus, the functional relationship between different influencing factors and the wear rate is established, that is, the wear rate is expressed as:

[0037] ϵ 3 = k · f ( r , θ , t , w , ρ , δ , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com