Nitride semiconductor structure and semiconductor light-emitting component

A nitride semiconductor, semiconductor technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low light extraction efficiency, complicated process, large resistance value, etc., to achieve optimal luminous efficiency, improve luminous efficiency, and uniform current diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The purpose of the present invention and its structural design and functional advantages will be described according to the following drawings and preferred embodiments, so as to have a more in-depth and specific understanding of the present invention.

[0034] First of all, in the description of the following embodiments, it should be understood that when it is indicated that a layer (or film) or a structure is disposed "on" or "under" another substrate, another layer (or film), or another structure , which can be "directly" located on other substrates, layers (or films), or another structure, or have more than one intermediate layer between them in an "indirect" manner, and the position of each layer can be explained with reference to the drawings .

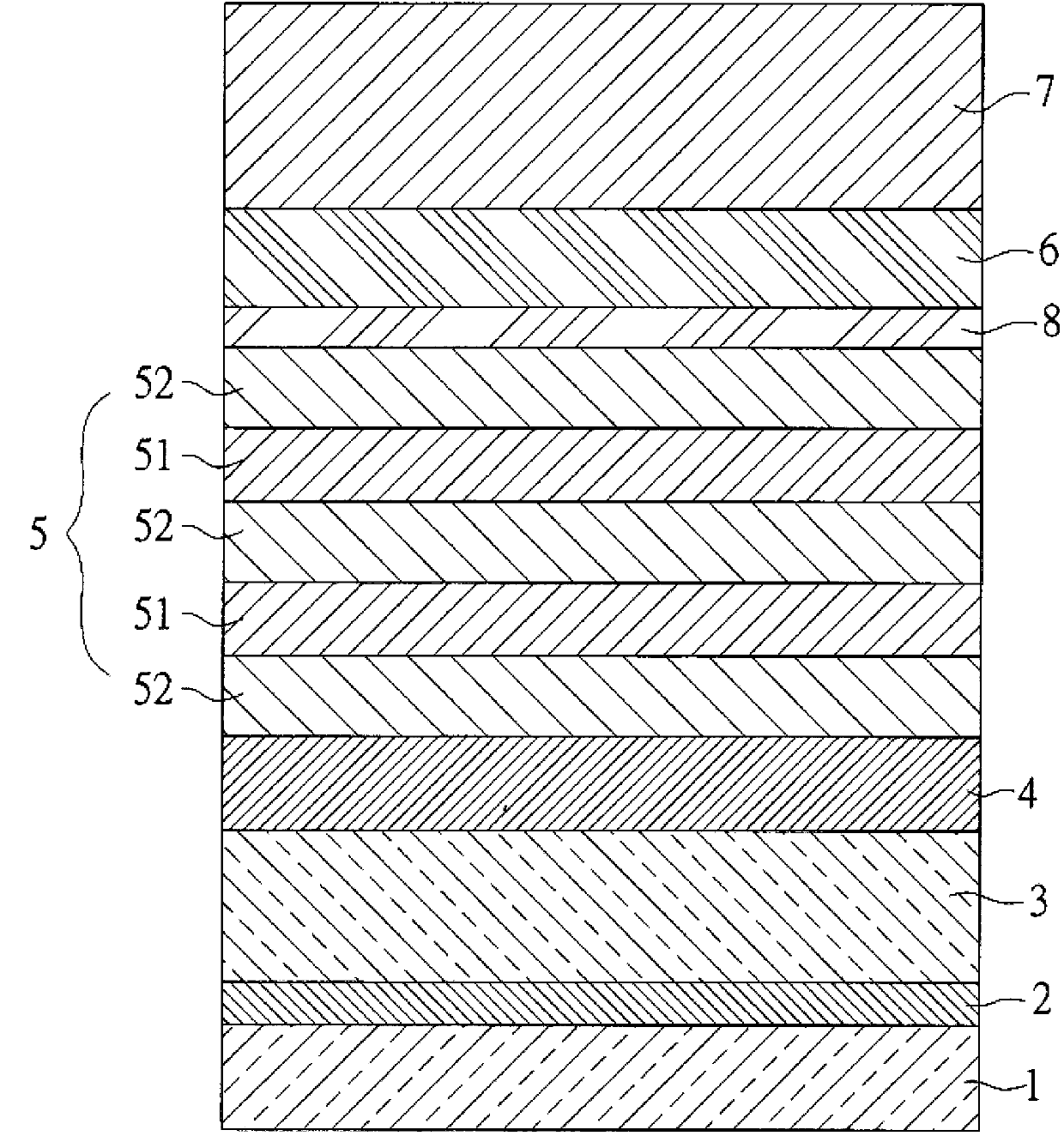

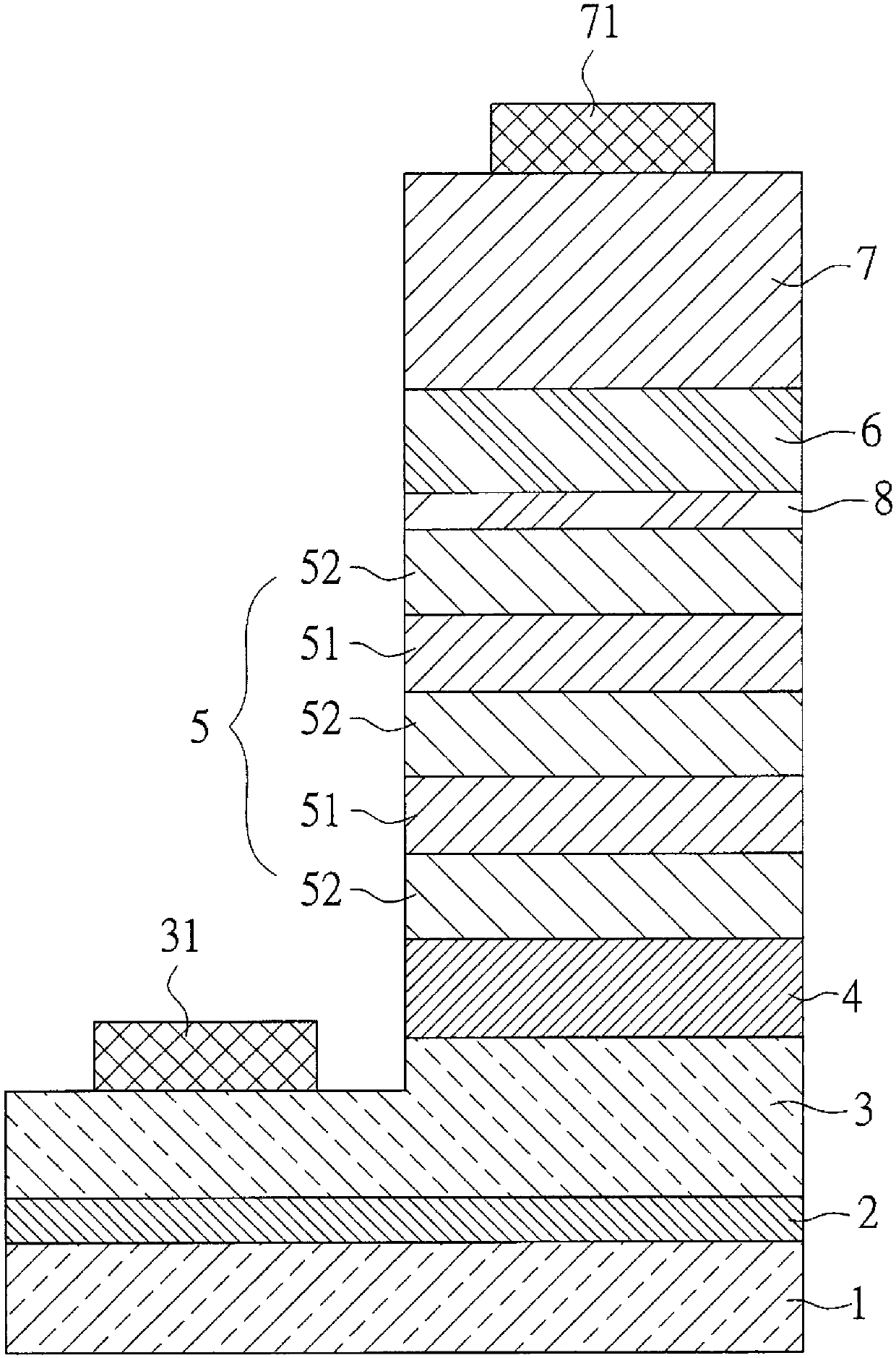

[0035] see figure 1As shown, it is a schematic cross-sectional view of a nitride semiconductor structure provided by a preferred embodiment of the present invention, which includes a first-type doped semiconductor layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com