Chromium slag pyrolysis treatment method with high efficiency, low consumption, and low pollution

A treatment method and low-polluting technology, applied in the direction of solid waste removal, etc., can solve the problems of great harm, waste of energy, reduction of reduction efficiency, etc., and achieve the effects of reducing the discharge of harmful substances, saving energy, and simplifying control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

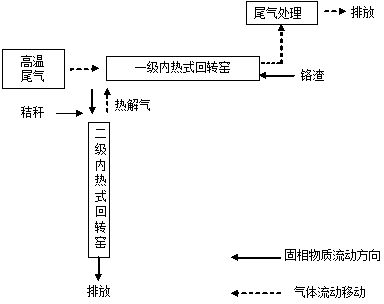

[0028] 1. After the chromium slag is ground to <2mm, it is sent to the tail of the first-stage internal heating rotary kiln, and then the first-stage internal heating rotary kiln is turned to make the chromium slag gradually drive from the kiln tail to the kiln head;

[0029] 2. The chromium slag is mixed with high-temperature exhaust gas at the head of the first-stage rotary kiln to be heated, and the temperature of the head of the first-stage rotary kiln is controlled at 600°C. The heated chromium slag enters the tail of the second-stage internal heating rotary kiln from the kiln head through a chain conveyor belt, and a silo is set at the upper part of the second-stage rotary kiln to add straw to mix the straw with the high-temperature chromium slag at a mixing ratio of straw : High temperature chromium slag=1:10. The mixed straw and chromium slag arrive at the kiln head of the secondary rotary kiln after 10 minutes of operation in the secondary rotary kiln, and are dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com