Novel three-section nickel-based screw-grinding waste plastic modification regeneration energy-saving equipment

An energy-saving equipment and a three-stage technology, applied in the field of plastic machinery, can solve the problems of affecting the quality and performance of plastic products, easy expansion of the screw, and unstable performance, so as to facilitate regeneration and modification, increase silk production efficiency, and realize product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

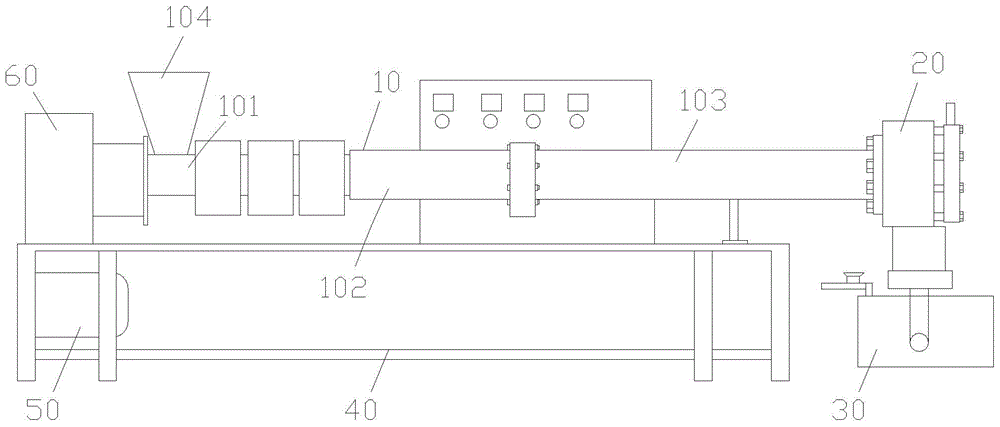

[0031] Such as figure 1 As shown, a new three-stage nickel-based screw grinding waste plastic modification regeneration energy-saving equipment mainly consists of two parts: the working part and the base bracket. There are three sections of grinding mechanism, the right end of the heating melting pipe 10 is connected with a wire outlet mechanism 20, a cooling device 30 is arranged at the lower end of the wire outlet mechanism 20, and the base support part mainly includes a base 40, an engine 50 and a transmission gearbox 60 arranged on the base 40, The engine 50 is connected with the transmission gearbox 60 through the transmission shaft, and the transmission gearbox 60 is connected with the heating fusion pipe 10 . The right end of the transmis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com