Preparation technology of continuous functionalized carbon fiber enhanced thermoplastic resin base prepreg tape

A technology of thermoplastic resin and functionalized carbon, which is applied in the direction of coating, etc., can solve the problems of complex process, difficult to dissolve, high viscosity of thermoplastic resin, etc., and achieve the effect of improving preparation efficiency, simplifying process flow and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

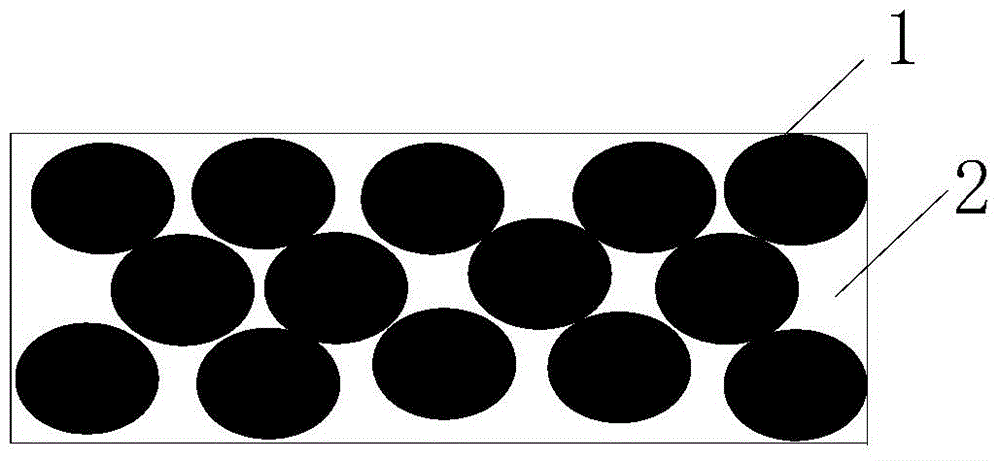

Image

Examples

Embodiment 1

[0032] The continuous functionalized carbon fiber obtained by surface etching is placed on the creel, and its surface energy is 50mJ / m 2 , the contact angle with water is 50°, enter the fiber opening equipment through the guide roller to open the fiber, mainly through the wind perpendicular to the functional carbon fiber to open the fiber, the functionalized carbon fiber tow width obtained after the fiber opening is the function before fiber opening 1 times the width of the carbon fiber tow. Then enter the spraying equipment to spray the thermoplastic resin powder suspension. The diameter of the formed spray droplet is controlled at 1mm, and the distance between the nozzle and the functionalized carbon fiber is 40cm. Wherein the thermoplastic resin powder suspension is selected as nylon 1010 powder with an average diameter of 10 μm, and its mass percentage concentration is 30%, and the surfactant is selected from polyurethane, and its mass percentage concentration is 6%, and t...

Embodiment 2

[0034] Place the continuous functionalized carbon fiber obtained by applying water-soluble slurry on the creel, and its surface energy is 120mJ / m 2 , the contact angle with water is 10°, and it enters the fiber opening equipment through the yarn guide roller to open the fibers, mainly through ultrasonic waves, and the width of the functionalized carbon fiber tow obtained after fiber opening is 100% of the width of the functionalized carbon fiber tow before fiber opening 3 times. Then enter the spraying equipment to spray the thermoplastic resin powder suspension, the diameter of the spray droplets formed is controlled at 100 μm, and the distance between the nozzle and the functionalized carbon fiber is 20cm. Among them, the thermoplastic resin powder suspension is selected from polyetheretherketone powder with an average diameter of 25 μm, and its mass percentage concentration is 3%, and the surfactant is selected from polyether, and its mass percentage concentration is 0.3%, ...

Embodiment 3

[0036] The continuous functionalized carbon fibers obtained by plasma grafting were placed on the creel with a surface energy of 108mJ / m 2 , the contact angle with water is 62°, enter the fiber opening equipment through the guide roller to open the fiber, mainly through the roller vibration to open the fiber, the width of the functionalized carbon fiber tow obtained after fiber opening is the width of the functionalized carbon fiber tow before fiber opening 2.6 times. Then enter the spraying equipment to spray the thermoplastic resin powder suspension, the diameter of the spray droplets formed is controlled at 320 μm, and the distance between the nozzle and the functionalized carbon fiber is 32cm. Wherein the thermoplastic resin powder suspension liquid chooses nylon 12 powder with an average diameter of 100 μm, and its mass percentage concentration is 22%, and the surfactant is selected polyvinylpyrrolidone, and its mass percentage concentration is 3.3%, and the residence tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface energy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com