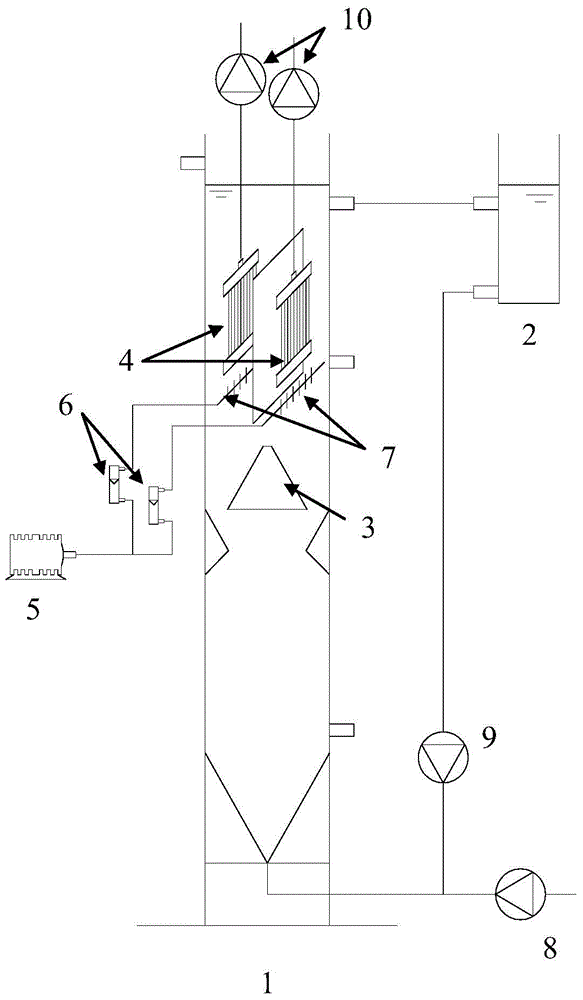

Integrated expanded granular sludge bed-membrane bioreactor whole-course autotrophy denitrification device and process thereof

A whole-process autotrophic denitrification and expanded granular sludge technology, applied in the field of environmental engineering, can solve problems such as insufficient to meet the mitigation of membrane fouling, and achieve the effects of shortening doubling time, alleviating membrane fouling, and effective combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0015] (1) Nitrogen-containing sewage (waste) water is firstly placed in the inlet well, and the temperature and pH of the inlet water are adjusted according to the feedback of the temperature and pH value in the reactor, so that the temperature and pH in the reactor are kept at 15-40°C, respectively. Between 6-9, preferably between 30-35°C, 8.0-8.5;

[0016] (2) Subsequently, the sewage (waste) water in the water inlet well is pumped into the reactor 1 through the water pump 8 through the water inlet provided at the bottom of the reactor. Along with the dissolved oxygen in the return water, part or half of the ammonia nitrogen in the influent water is first converted to nitrite nitrogen by the aerobic ammonia oxidizing bacteria on the surface of the granular sludge. Then the remaining ammonia nitrogen in the influ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com