Shale ceramsite cultured stones, and preparation method and application thereof

A technology of shale ceramsite and cultural stone, which is applied in the field of building materials to achieve the effect of easy cutting, easy pasting, and easy engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

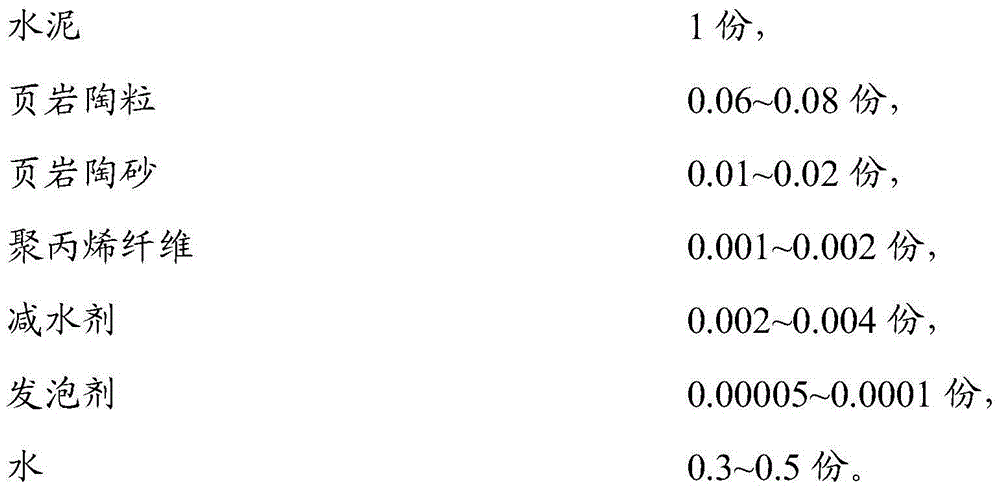

Embodiment 1

[0028] A preparation method of shale ceramsite cultural stone, comprising the following steps:

[0029] (1) Weigh 1 ton of white cement, 60kg of shale ceramsite, 20kg of shale ceramsite, and 1kg of polypropylene fiber and add them to the mixer in turn. After stirring for 1 minute, add 4kg of water reducing agent, 0.1kg of foaming agent and 300kg of foaming agent. The mixture of water was stirred for another 2 minutes to obtain a slurry;

[0030] In step (1), the particle size of shale ceramsite is 5-15mm; the particle size of shale ceramic sand is ≤5mm, and the particle size is divided into three grades according to ≤1mm, 1-3mm and 3-5mm, and The mass ratio between the three grades is 10:35:40.

[0031] (2) Pour the slurry obtained in step (1) into the mold by pumping or manually, after spreading, vibrating, and smoothing, after 30 minutes, carry out the second slurry collection and smearing, and wait for the final setting to cover the plastic film Or non-woven fabric, after...

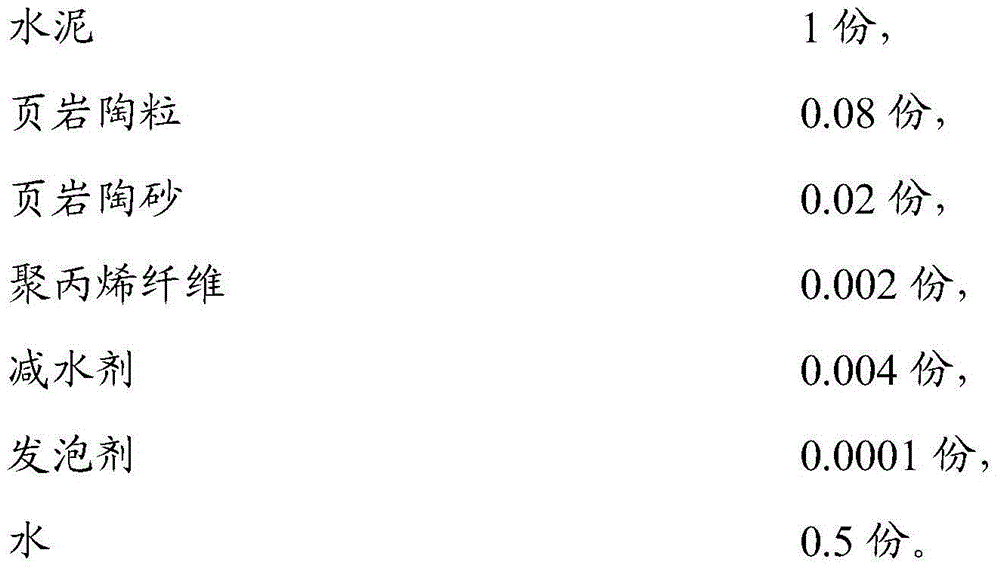

Embodiment 2

[0035] A preparation method of shale ceramsite cultural stone, comprising the following steps:

[0036](1) Weigh 1 ton of cement, 80kg of shale ceramsite, 20kg of shale ceramsite, and 2kg of polypropylene fiber and add them to the mixer in turn. After stirring for 2 minutes, add 4kg of water reducing agent, 0.1kg of foaming agent and 500kg of foaming agent. The mixture of water was stirred for another 5 minutes to obtain a slurry;

[0037] In step (1), the particle size of shale ceramsite is 5-15mm; the particle size of shale ceramic sand is ≤5mm, and the particle size is divided into three grades according to ≤1mm, 1-3mm and 3-5mm, and The mass ratio between the three grades is 15:35:50.

[0038] (2) Pour the slurry obtained in step (1) into the mold by pumping or manually, after spreading, vibrating, and smoothing, after 30 minutes, carry out the second slurry collection and smearing, and wait for the final setting to cover the plastic film Or non-woven fabric, after curin...

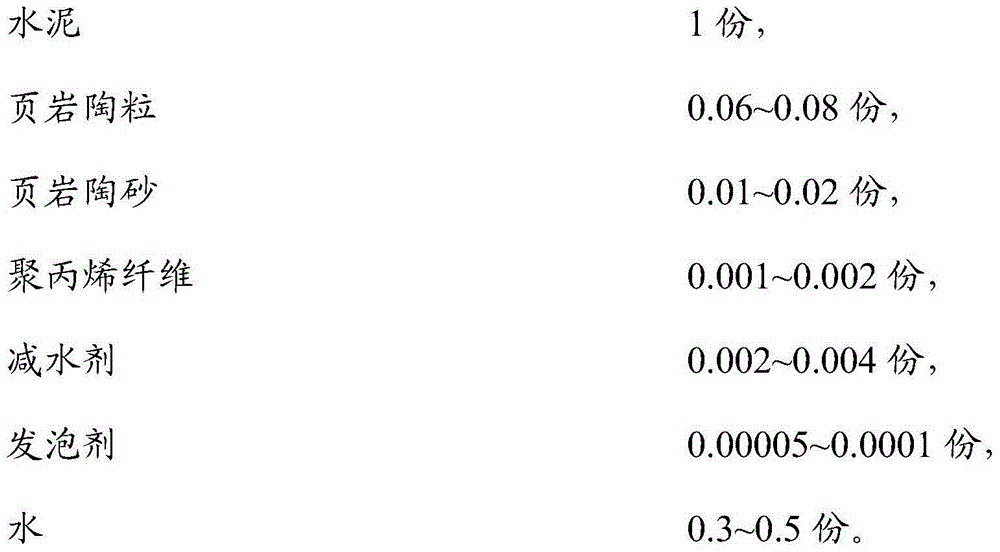

Embodiment 3

[0042] A preparation method of shale ceramsite cultural stone, comprising the following steps:

[0043] (1) Weigh 1 ton of white cement, 80kg of shale ceramsite, 10kg of shale ceramsite, and 2kg of polypropylene fiber, respectively, and add them to the mixer in turn. After stirring for 2 minutes, add 2kg of water reducing agent, 0.05kg of foaming agent and The mixture of 500kg water was stirred for 5min to obtain a slurry;

[0044] In step (1), the particle size of shale ceramsite is 5-15mm; the particle size of shale ceramic sand is ≤5mm, and the particle size is divided into three grades according to ≤1mm, 1-3mm and 3-5mm, and The mass ratio between the three grades is 10:45:40.

[0045] (2) Pour the slurry obtained in step (1) into the mold by pumping or manually, after spreading, vibrating, and smoothing, after 30 minutes, carry out the second slurry collection and smearing, and wait for the final setting to cover the plastic film Or non-woven fabric, after curing for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com