Emulsion-type steel plate cold-rolling lubricating oil composition

A lubricating oil composition, emulsified technology, applied in lubricating compositions, petroleum industry, base materials, etc., can solve the problems of unstable emulsification and poor detergency, and achieve good annealing detergency, good oxidation resistance and high temperature resistance Sexuality and uniform adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

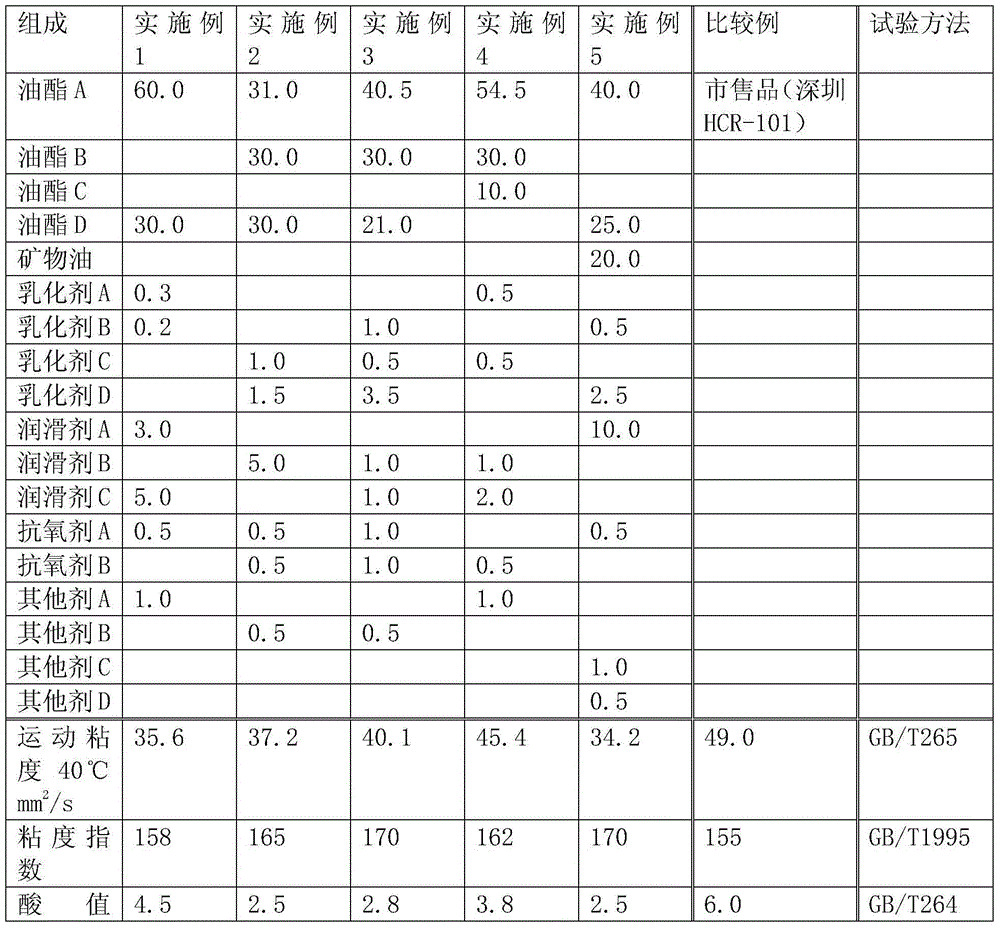

[0028] The specific substances and mass fractions of each component selected in Examples 1 to 5 are as follows in Tables 1 and 2:

[0029] Table 1

[0030]

[0031]

[0032] Table 2 Description of Raw Materials

[0033] Olein A

Special palm oil (melting point 12°C)

Oil B

trimethylolpropane oleate

Oil C

pentaerythritol oleate

Oil D

Trimethylolpropane Coconut Oleate

The viscosity is 10.0mm2 / s at 40°C, and the freezing point is -35°C base oil

Emulsifier A

C 18 Polyoxyethylene ester of fatty acid polymer (number average molecular weight 5000, HLB value 6-8)

Emulsifier B

Fatty acid ester of polyoxyethylene (number average molecular weight 1500, HLB value 6-10)

Emulsifier C

Sorbitan polyoxyethylene oleate (number average molecular weight 3000, HLB value 9-12)

Emulsifier D

C 18 Polyoxyethylene polyoxypropylene fatty acid polymer (number average molecular weight 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com