Preparation method of tungsten-aluminum nitride-hafnium boride composite material

A composite material, a technology of hafnium boride, is applied in the field of preparation of tungsten-aluminum nitride-hafnium boride composite materials, and can solve the problem of internal stress micro-cracks, grain growth of ceramic materials, and influence on the mechanical properties of hafnium boride ceramic materials. and its application, to achieve the effect of excellent performance and avoid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

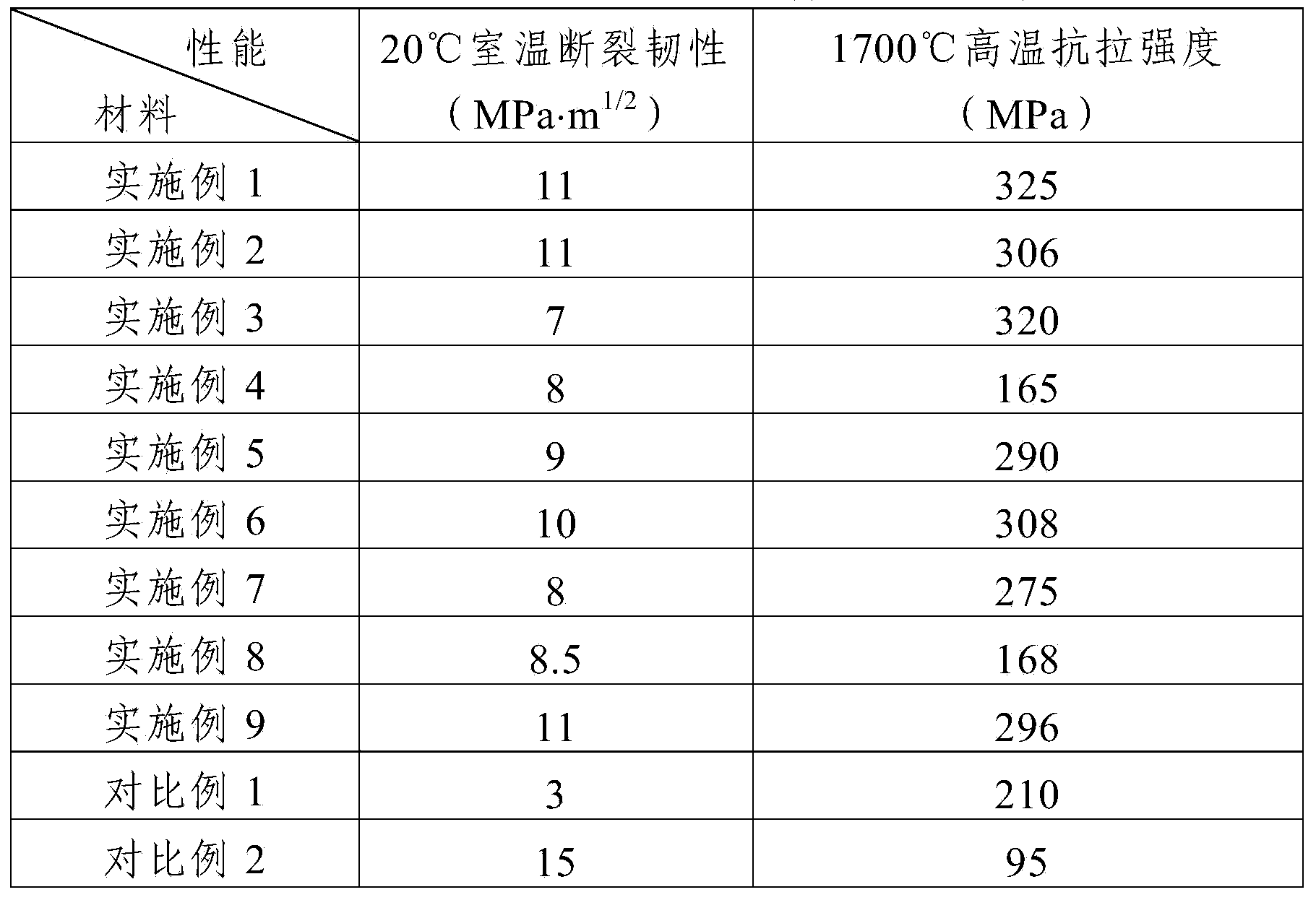

Examples

Embodiment 1

[0021] The preparation method of the tungsten-aluminum nitride-hafnium boride composite material in this embodiment includes the following steps:

[0022] Step 1. Put the mixed powder of tungsten powder, aluminum nitride powder and hafnium boride powder and absolute ethanol in a planetary ball mill at a volume ratio of 1:1. Ball milling and mixing for 20 hours under the same conditions to obtain a slurry; the mass percentages of tungsten powder, aluminum nitride powder and hafnium boride powder in the mixed powder are respectively: 35% of tungsten powder, 5% of aluminum nitride powder, and 60% of hafnium boride powder %; the particle size of the hafnium boride powder and the aluminum nitride powder is not more than 5 μm, the particle size of the tungsten powder is not more than 3 μm, the mass purity of the hafnium boride powder is not less than 98%, the nitride The mass purity of aluminum powder and tungsten powder is not less than 99%;

[0023] Step 2, drying the slurry desc...

Embodiment 2

[0027] The preparation method of the tungsten-aluminum nitride-hafnium boride composite material in this embodiment includes the following steps:

[0028] Step 1. Put the mixed powder of tungsten powder, aluminum nitride powder and hafnium boride powder and absolute ethanol in a planetary ball mill at a volume ratio of 1:1. Ball milling and mixing for 20 hours under the same conditions to obtain a slurry; the mass percentages of tungsten powder, aluminum nitride powder and hafnium boride powder in the mixed powder are respectively: 80% of tungsten powder, 10% of aluminum nitride powder, and 10% of hafnium boride powder %; the particle size of the hafnium boride powder and the aluminum nitride powder is not more than 5 μm, the particle size of the tungsten powder is not more than 3 μm, the mass purity of the hafnium boride powder is not less than 98%, the nitride The mass purity of aluminum powder and tungsten powder is not less than 99%;

[0029] Step 2, drying the slurry des...

Embodiment 3

[0033] The preparation method of the tungsten-aluminum nitride-hafnium boride composite material in this embodiment includes the following steps:

[0034] Step 1. Put the mixed powder of tungsten powder, aluminum nitride powder and hafnium boride powder and absolute ethanol in a planetary ball mill at a volume ratio of 1:1. Ball milling and mixing for 20 hours under the same conditions to obtain a slurry; the mass percentages of tungsten powder, aluminum nitride powder and hafnium boride powder in the mixed powder are respectively: 39% of tungsten powder, 1% of aluminum nitride powder, and 60% of hafnium boride powder %; the particle size of the hafnium boride powder and the aluminum nitride powder is not more than 5 μm, the particle size of the tungsten powder is not more than 3 μm, the mass purity of the hafnium boride powder is not less than 98%, the nitride The mass purity of aluminum powder and tungsten powder is not less than 99%;

[0035] Step 2, drying the slurry desc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com