A kind of nb‑si‑ti‑ta‑b alloy material and preparation method thereof

An alloy material, nb-si-ti-ta-b technology, applied in the field of alloy preparation, can solve the problems of low density, low elastic modulus, high temperature strength, etc., and achieve the effect of improving high temperature strength, improving room temperature tensile strength and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

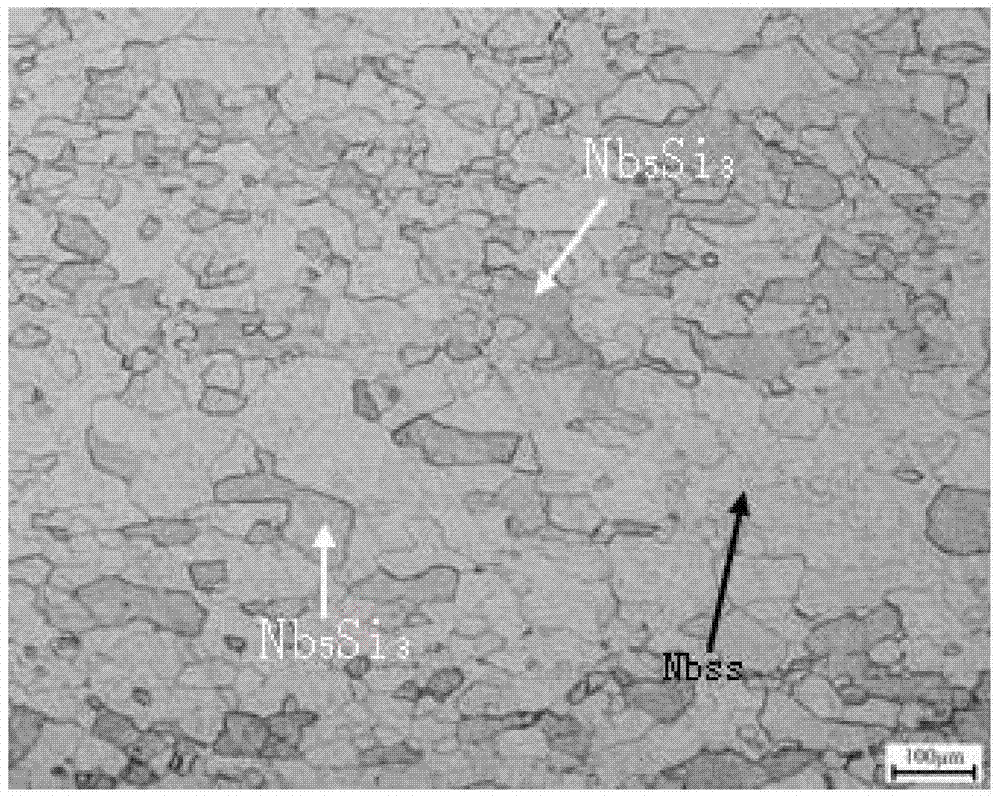

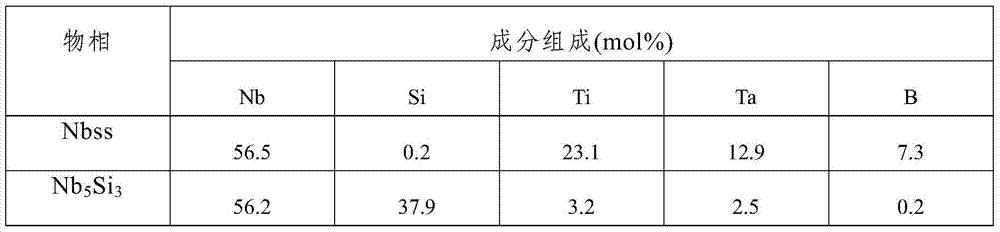

[0020] The Nb-Si-Ti-Ta-B alloy material of this embodiment is characterized in that it is made of the following atomic percentage raw materials: Si 10%, Ti 20%, Ta 10%, B 5%, and the balance is Nb and not Avoid impurities.

[0021] The method for preparing the Nb-Si-Ti-Ta-B alloy material in this embodiment comprises the following steps:

[0022] Step 1. Mix silicon powder, titanium powder, tantalum powder, boron powder and niobium powder evenly and press them into electrodes, then place the electrodes in a vacuum consumable arc melting furnace, and place them in a vacuum degree of less than 1×10 -4 Arc smelting 5 times under the condition of Pa to obtain Nb-Si-Ti-Ta-B alloy ingot; the smelting current of the arc smelting is 6kA, and the smelting voltage is 30V. Preferably, the mass purity of the silicon powder is not less than 99.99%, the mass purity of the titanium powder is not less than 99.99%, the mass purity of the tantalum powder is not less than 99.9%, and the mass pu...

Embodiment 2

[0030] The Nb-Si-Ti-Ta-B alloy material of this embodiment is characterized in that it is made of the following atomic percentage raw materials: Si 6%, Ti 16%, Ta 5%, B 2%, and the balance is Nb and not Avoid impurities.

[0031] The method for preparing the Nb-Si-Ti-Ta-B alloy material in this embodiment comprises the following steps:

[0032] Step 1. Mix silicon powder, titanium powder, tantalum powder, boron powder and niobium powder evenly and press them into electrodes, then place the electrodes in a vacuum consumable arc melting furnace, and place them in a vacuum degree of less than 1×10 -4 Arc smelting 3 times under the condition of Pa to obtain Nb-Si-Ti-Ta-B alloy ingot; the smelting current of the arc smelting is 5kA, the smelting voltage is 20V, preferably, the mass purity of the silicon powder is not less than 99.99%, the mass purity of the titanium powder is not less than 99.99%, the mass purity of the tantalum powder is not less than 99.9%, and the mass purity o...

Embodiment 3

[0036] The Nb-Si-Ti-Ta-B alloy material of this embodiment is characterized in that it is made of the following atomic percentage raw materials: Si 20%, Ti 30%, Ta 15%, B 8%, and the balance is Nb and not Avoid impurities.

[0037] The method for preparing the Nb-Si-Ti-Ta-B alloy material in this embodiment comprises the following steps:

[0038] Step 1. Mix silicon powder, titanium powder, tantalum powder, boron powder and niobium powder evenly and press them into electrodes, then place the electrodes in a vacuum consumable arc melting furnace, and place them in a vacuum degree of less than 1×10 -4 Under the condition of Pa, arc melting is performed 6 times to obtain Nb-Si-Ti-Ta-B alloy ingot; the melting current of the arc melting is 7kA, and the melting voltage is 40V. Preferably, the mass purity of the silicon powder is not less than 99.99%, the mass purity of the titanium powder is not less than 99.99%, the mass purity of the tantalum powder is not less than 99.9%, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com