A method for improving room temperature fracture toughness of nb‑Si based multi-component alloys

A fracture toughness and alloy technology, applied in the field of ultra-high temperature structural materials, can solve problems such as poor fracture toughness, and achieve the effects of high density, uniform phase distribution, and improved fracture toughness at room temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

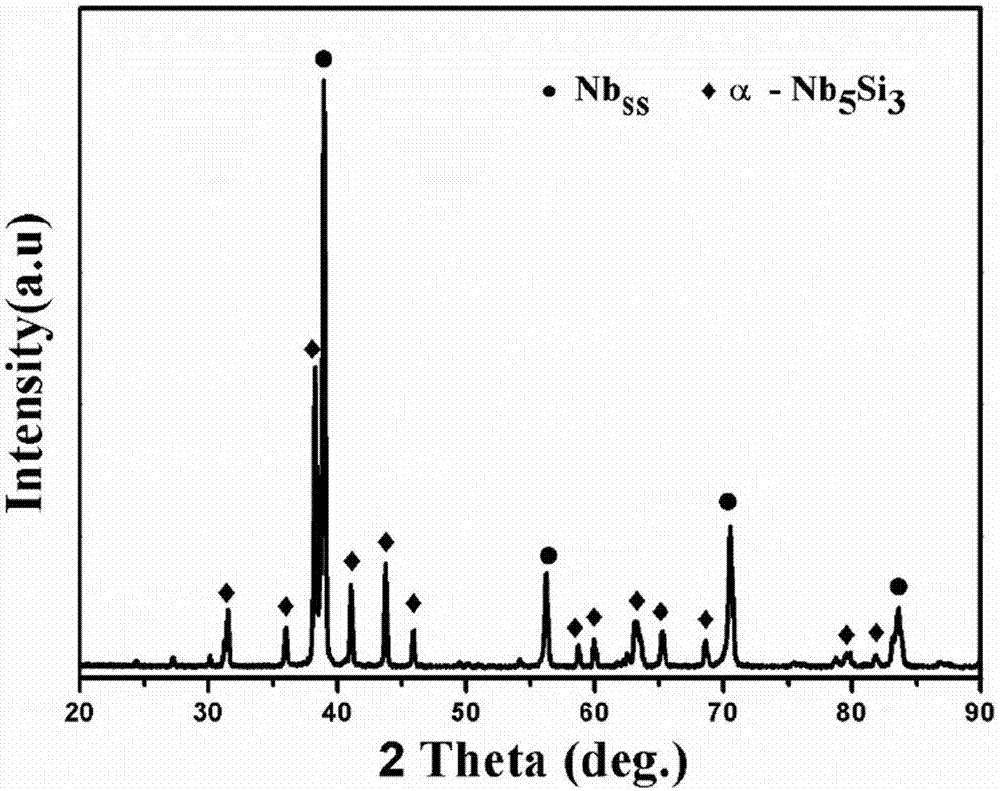

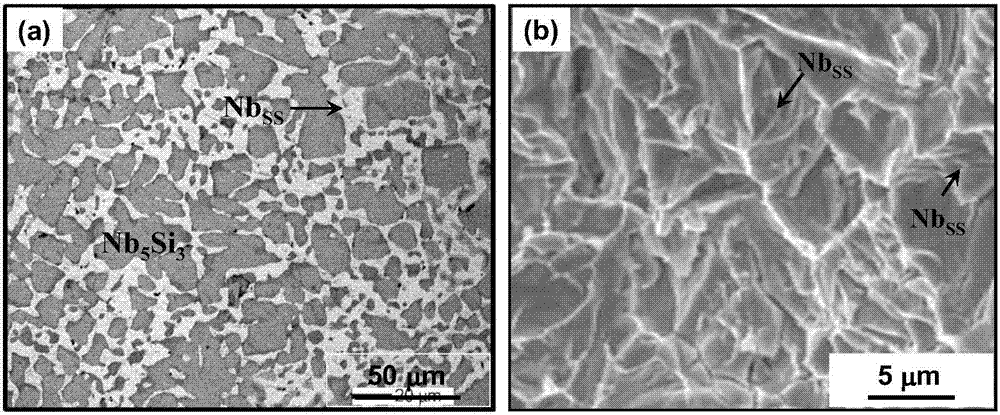

[0033] Using the combination of plasma rotating electrode atomization technology and spark plasma sintering technology to improve room temperature fracture toughness of Nb-Si based multi-component alloys, the steps are as follows:

[0034] 1. Using Nb, Si, Ti, Cr, Al as synthetic raw materials, using vacuum non-consumable arc melting technology and induction melting casting technology to obtain Nb-22Si-24Ti-2Cr-2Al alloy rods, the size is Φ75mm×150mm, the surface is ground light, dry after washing;

[0035] 2. Fix the Nb-22Si-24Ti-2Cr-2Al alloy rod in the sample loading room of the plasma rotary electrode atomization equipment, and fill the sealing device with high-purity argon (99.99%) for atmosphere protection after vacuumizing;

[0036]3. Set the process parameters such as plasma gun power, plasma arc current and electrode rod speed, so that the end of the high-speed rotating Nb-22Si-24Ti-2Cr-2Al alloy rod is melted, and the melted body is atomized into liquid droplets unde...

Embodiment 2

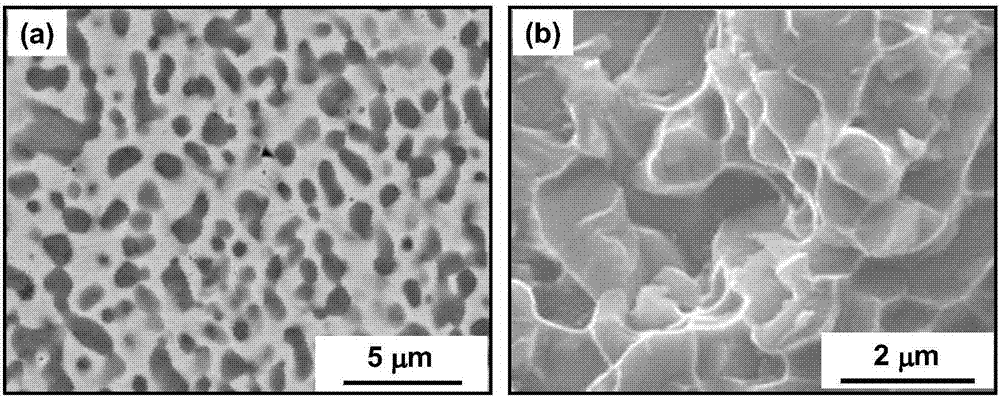

[0043] Using the plasma rotating electrode atomization method + spark plasma sintering method to improve the room temperature fracture toughness of Nb-Si based multi-component alloys, the steps are as follows:

[0044] 1. Using Nb, Si, Ti, Cr, and Al as synthetic raw materials, the Nb-18Si-24Ti-2Cr-2Al alloy rod is obtained by using vacuum non-consumable arc melting technology and induction melting casting technology, and the sample size is Φ75mm×150mm;

[0045] 2. Fix the Nb-18Si-24Ti-2Cr-2Al alloy sample in the sample loading room of the plasma rotating electrode equipment, and fill the sealing device with high-purity argon (99.99%) for atmosphere protection after vacuumizing;

[0046] 3. Set the process parameters such as plasma gun power, plasma arc current and electrode rod speed, so that the end of the high-speed rotating Nb-18Si-24Ti-2Cr-2Al alloy rod is melted, and the melted body is atomized into liquid droplets under the action of centrifugal force. Shot out, while r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com