An electron beam melting device and a method for preparing a niobium-based super high temperature alloy using the device

An electron beam smelting and ultra-high temperature alloy technology is applied in the field of electron beam smelting device and the preparation of niobium-based ultra-high temperature alloy by using the device, which can solve the problems of rapid oxidation and unusability, and achieve the improvement of tensile strength and oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

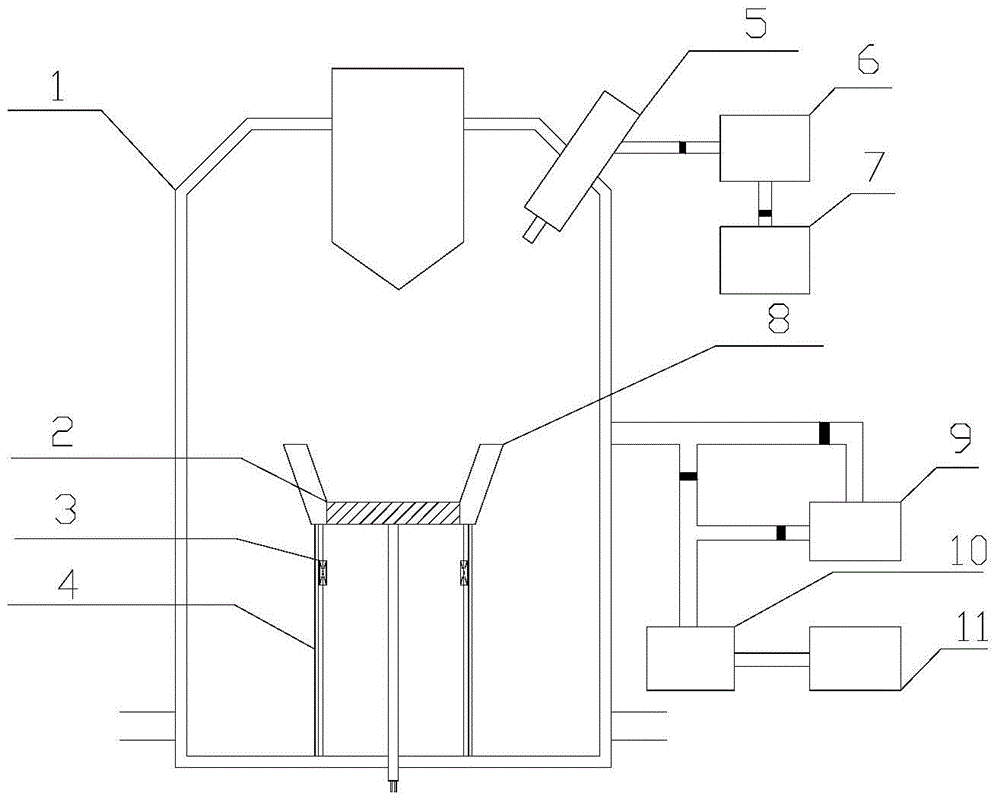

[0029] A method for preparing a niobium-based super high temperature alloy, comprising the following process steps:

[0030] The ratio of Nb-1Zr niobium-based super high temperature alloy in this embodiment is as follows: Zr: 1.0%; Nb: balance.

[0031] ①Material preparation: According to the alloy ratio, add the alloying element metal raw material Zr into the feeding funnel, put the metal raw material Nb in the water-cooled copper crucible 8 of the electron beam melting furnace, and keep the temperature of the water-cooled copper crucible 8 during the whole preparation process is 200°C.

[0032] ② Preheating: Close the door of the electron beam melting furnace, turn on the electron gun mechanical pump 7, electron gun diffusion pump 6, melting chamber mechanical pump 11, melting chamber Roots pump 10, melting chamber diffusion pump 9, so that the electron beam melting furnace melts The vacuum degree of chamber 1 is less than 5×10 -2 Pa, the vacuum degree of the electron gun ...

Embodiment 2

[0038] The proportion of PWC-11 niobium-based super high temperature alloy in this embodiment is as follows: W: 10%; Zr: 1.0%; C: 0.1; Nb: balance.

[0039] ①Material preparation: According to the alloy ratio, add the alloying element metal raw materials W and Zr into the feeding funnel, and place the rest of the elemental metal raw materials in the water-cooled copper crucible 8 of the electron beam melting furnace according to the ratio. During the whole preparation process, keep water-cooled The temperature of the copper crucible 8 was 200°C.

[0040] ② Preheating: Close the door of the electron beam melting furnace, turn on the electron gun mechanical pump 7, electron gun diffusion pump 6, melting chamber mechanical pump 11, melting chamber Roots pump 10, melting chamber diffusion pump 9, so that the electron beam melting furnace melts The vacuum degree of chamber 1 is less than 5×10 -2 Pa, the vacuum degree of the electron gun chamber is less than 5×10 -3 Pa; set the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| process yield | aaaaa | aaaaa |

| process yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com