nb‑ti‑zr‑nb 5 the si 3 Composite material and its preparation method

A technology of nb-ti-zr-nb5si3, composite material, applied in the field of Nb-Ti-Zr-Nb5Si3 composite material and its preparation, can solve the problem that room temperature fracture toughness, high temperature mechanical properties and oxidation resistance have not reached a good balance, The mechanical properties and anti-oxidation properties are reduced, and the mechanical properties at room temperature and high temperature are poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

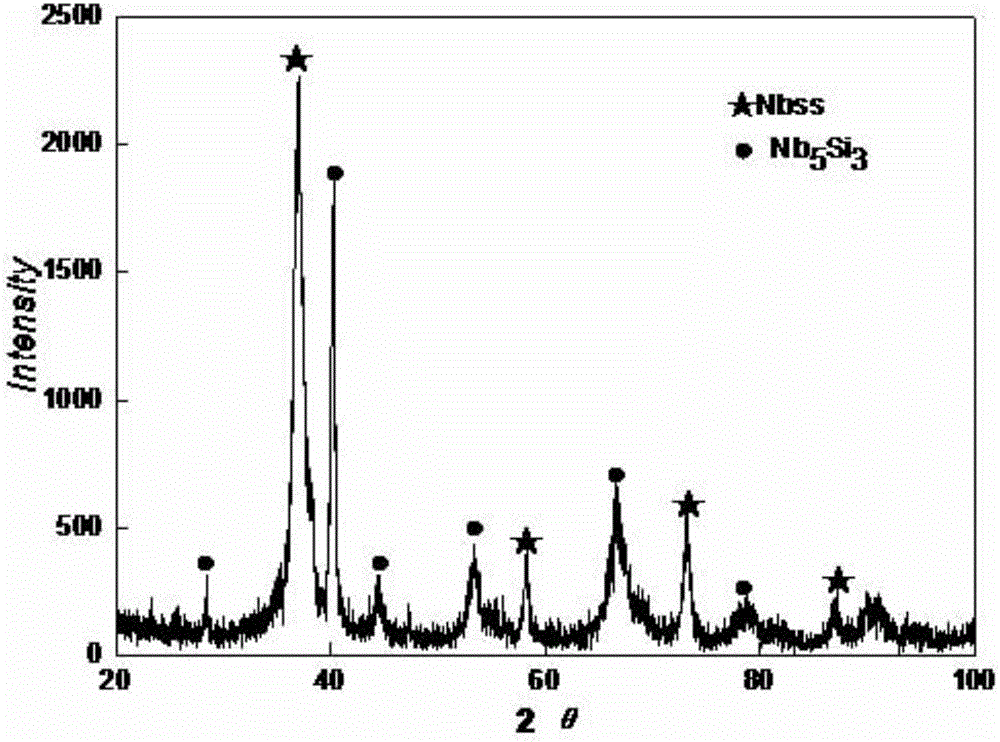

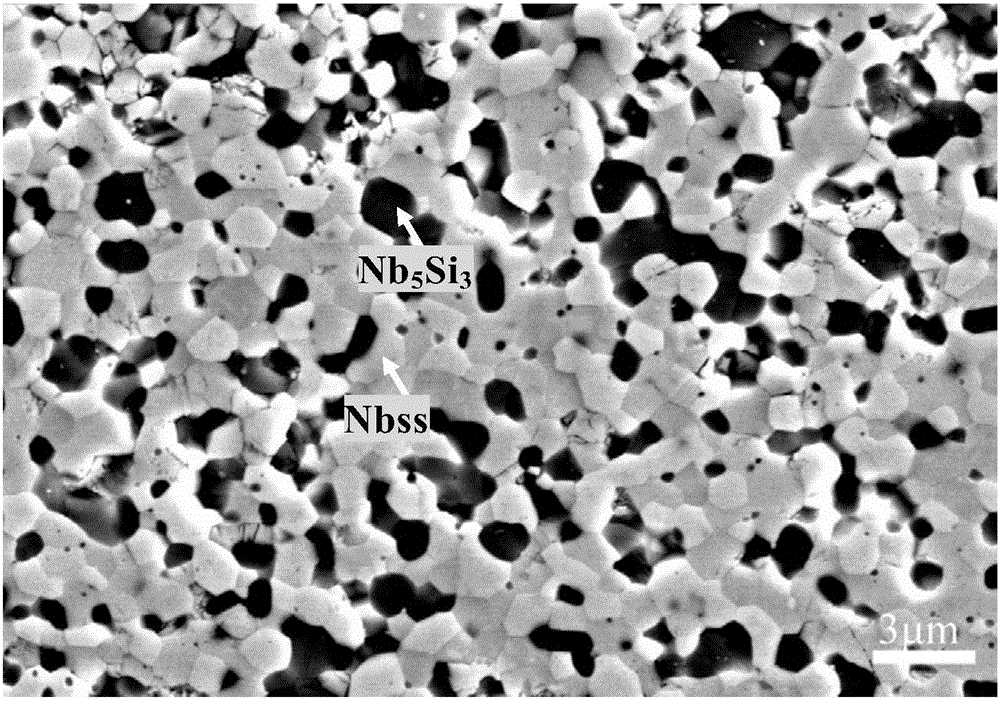

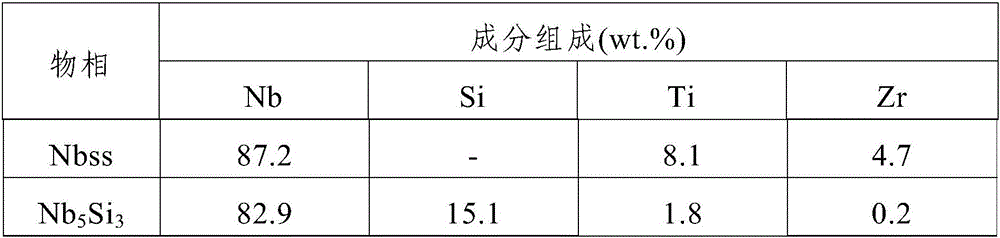

[0027] In this embodiment Nb-Ti-Zr-Nb 5 Si 3 The composite material is made of the following raw materials in mass percentage: Titanium 5%, Zirconium 3%, Nb 5 Si 3 25%, and the balance is niobium; the raw materials are all powdery raw materials, namely: titanium is titanium powder with a particle size not greater than 5 μm, zirconium is zirconium powder with a particle size not greater than 6 μm, Nb 5 Si 3 Nb with a particle size not greater than 5 μm 5 Si 3 Niobium powder, niobium is niobium powder with a particle size not greater than 8 μm, of which titanium powder, zirconium powder and Nb 5 Si 3 The mass purity of the niobium powder is not less than 99%, and the mass purity of the niobium powder is not less than 99.9%.

[0028] In this embodiment Nb-Ti-Zr-Nb 5 Si 3 The preparation method of composite material comprises the following steps:

[0029] Step 1. Weigh each raw material according to the mass percentage, then ball mill the weighed raw materials and mix them...

Embodiment 2

[0035] This embodiment is the same as embodiment 1, wherein the difference is: Nb-Ti-Zr-Nb 5 Si 3 The composite material is made of the following raw materials in mass percentage: titanium 15%, zirconium 8%, Nb 5 Si 3 55%, and the balance is niobium.

[0036] Nb-Ti-Zr-Nb prepared in this embodiment 5 Si 3 The room temperature fracture toughness of the composite material is 15MPa m 1 / 2 ; Compressive strength at 1300°C is 1024MPa; material loss after oxidation in air at 1200°C for 100h is 0.08mg / cm 2 , indicating that the composite material has the characteristics of high strength, high toughness and excellent oxidation resistance, and can be used in high temperature and ultra-high temperature air environments.

Embodiment 3

[0038] This embodiment is the same as embodiment 1, wherein the difference is: Nb-Ti-Zr-Nb 5 Si 3 The composite material is made of the following raw materials in mass percentage: titanium 8%, zirconium 4.5%, Nb 5 Si 3 35%, the balance is niobium.

[0039] Nb-Ti-Zr-Nb prepared in this embodiment 5 Si 3 The room temperature fracture toughness of the composite is 23MPa m 1 / 2 ; Compressive strength at 1300°C is 812MPa; material loss after oxidation in air at 1200°C for 100h is 0.09mg / cm 2 , indicating that the composite material has the characteristics of high strength, high toughness and excellent oxidation resistance, and can be used in high temperature and ultra-high temperature air environments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com