Anti-cold-stress nutritional preparation for quails

A nutritional preparation and cold stress technology, which is applied in application, animal feed, additional food elements, etc., can solve the problems of increasing production costs and carbon emissions, improve production performance and disease resistance, improve bactericidal power, and enhance resistance The effect of cold stress ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

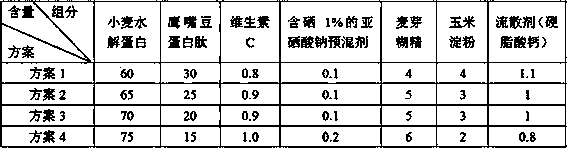

[0025] Example 1 An anti-cold stress nutritional preparation for quail, prepared by the following method:

[0026] (1) Preparation of wheat hydrolyzed protein: put 9~10wt% gluten powder suspension solution in the enzyme reactor, heat to 50°C, adjust the pH to 8.0~8.3 with 1mol / L sodium hydroxide solution, and then press The ratio of enzyme to protein is 1:100 (mass ratio), add alkaline protease, drop sodium hydroxide solution during the reaction to stabilize the pH at 8.0~8.3, react for 2.5~3 hours, add HCl solution to adjust the pH to 7.0, Hydrolyze with 0.2~0.3% (mass percentage) flavor enzyme for 1.5~2 hours, heat the reaction solution to boiling and keep it for 5~10 minutes to inactivate the enzyme, cool to 25~30°C, then centrifuge at 2000 rpm for 10 minutes, and The supernatant is spray-dried to obtain the wheat hydrolyzed protein. Wheat protein hydrolyzate is also commercially available.

[0027] (2) Preparation of chickpea protein peptide: 8~10wt% chickpea protein pow...

Embodiment 2

[0032] Embodiment 2 The following tests further illustrate the present invention's use effect:

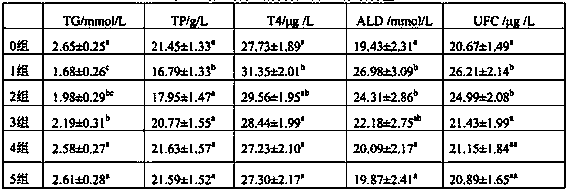

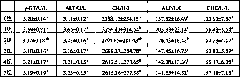

[0033](1) Effect of the preparation of the present invention on physiological and biochemical indicators related to cold stress in quail in a cold environment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com