Medium temperature sintered multilayer ceramic capacitor dielectric material

A capacitor dielectric and multilayer ceramic technology, which is applied in the field of X8R multilayer ceramic capacitor dielectric materials and its preparation, can solve the problems of high sintering temperature and inability to meet the use of Ag-Pd electrodes, and achieve lower sintering temperature and excellent dielectric Performance, the effect of promoting mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

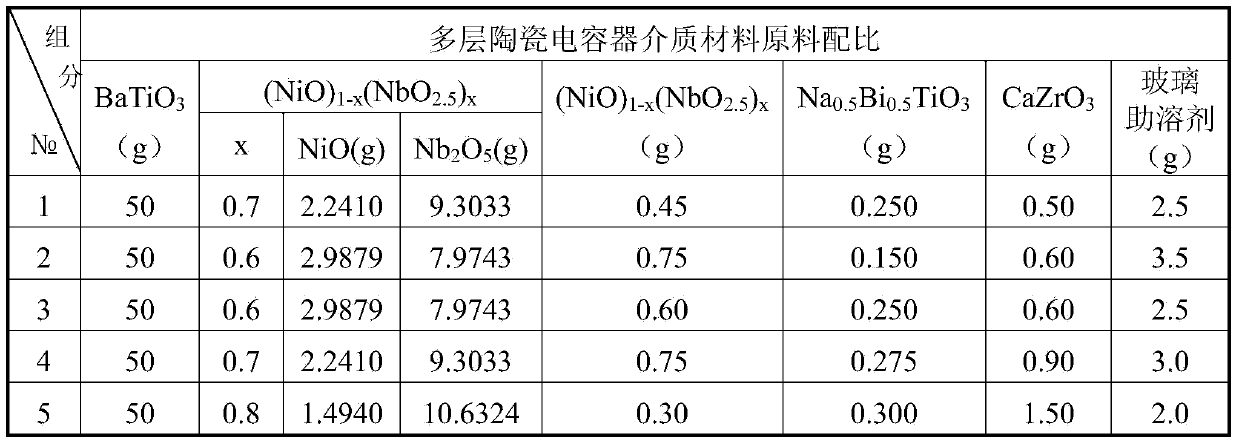

Examples

Embodiment 1

[0031] First, weigh and analyze 2.6497g Na of pure grade (≥99%) with electronic balance 2 CO 3 , 11.6490g Bi 2 o 3 and 7.9898gTiO 2 Mix, use deionized water as the ball milling medium, dry and sieve after ball milling for 4 hours, calcined at 950°C, and keep warm for 4 hours to obtain Na 0.5 Bi 0.5 TiO 3 ;

[0032] 2.2410g NiO and 9.3033g Nb 2 o 5 , mixed, with deionized water as the ball milling medium, after ball milling for 4 hours, dried, sieved, calcined at 1000°C, and kept for 2 hours to obtain (NiO) 0.3 (NbO 2.5 ) 0.7 Compound, ball milled for the second time for 6 hours, dried, passed through 80 mesh sieve for subsequent use;

[0033] Then 22.3291g CaCO 3 and 27.5114 g ZrO 2 Mix, use deionized water as the ball milling medium, dry and sieve after ball milling for 4 hours, calcined at 1000°C, and keep warm for 2 hours to obtain CaZrO3 ;

[0034] 17g TiO 2 , 34g H 3 BO 3 , 26g ZnO and 23g Bi 2 o 3 Fully mixed, melted and quenched, ground and passed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com