Ultra-high-strength polyurethaneurea supermolecular hydrogel and preparation method thereof

A technology of supramolecular hydrogel and polyurethane urea, which is applied in the field of polyurethane urea supramolecular hydrogel and its preparation, can solve the problems of poor mechanical properties of polyurethane hydrogel and the like, and achieve excellent processing performance and excellent tensile performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of ultrahigh-strength polyurethane urea supramolecular hydrogel, comprising the steps of:

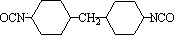

[0034] Step 1) Dissolve polyethylene glycol, polyester diol, and hydrophilic chain extender in a solvent, then add diisocyanate and catalyst, PEG: polyester diol: hydrophilic chain extender: diisocyanate The molar ratio is 2.5: 2.5: 4: X, and the temperature is 70-80°C for 2-4 hours;

[0035] Step 2) According to the molar ratio of PEG: polyester diol: hydrophilic chain extender: diisocyanate: small molecule chain extender = 2.5: 2.5: 4: X: 5, add the small molecule chain extender at a temperature of 50 - 70 ℃, stirring reaction for 1 - 2 hours;

[0036] Step 3) By PEG: Polyester Diol: Hydrophilic Chain Extender: Diisocyanate: Small Molecule Chain Extender: H 2 The molar ratio of O is 2.5: 2.5: 4: X: 5: X-14, adding chain extender water, at a temperature of 50-60 °C, stirring and reacting for 16-72 hours;

[0037] Step 4) After the reaction is over, pour the...

Embodiment 1

[0046] Its synthetic route is:

[0047]

[0048] The specific steps of the synthesis are as follows: before the experiment, the temperature of PEG 2k and PBA 2k was raised to 120°C, vacuum dehydrated for 1 hour, poured into a four-necked flask equipped with a thermometer, reflux condenser and stirring rod, and kept at 60°C; then adding The acetone solution of IPDI and DMBA was chain-extended, stirred at a constant speed for 10 min, and catalyst CT-E229 was added, the temperature was raised to 75°C, and the reaction was continued for 3 h; when the titration and infrared monitoring results reached the theoretical NCO content, BDO was added to extend the chain for 1 h. Also when the theoretical NCO content is reached, add water to extend the chain until the NCO disappears (infrared monitoring). After the reaction, the obtained solution is poured into a mold for molding. After the solvent evaporates, the polymer film is swelled in distilled water until the swelling balance is r...

Embodiment 2

[0057] This example provides a method for synthesizing polyurethaneurea hydrogel with high strength and shape memory function. The specific steps are as follows:

[0058] Add IPDI to the acetone solution of PEG 2k, PCL 4k and DMBA, then add 5 μl catalyst dibutyltin dilaurate, and react at 75 °C for 3 h. Then, ethylenediamine was added to the reaction flask, and the mixture was stirred and reacted at 30°C for 1 h under the protection of nitrogen. Finally, water is added for chain extension until the NCO disappears. After the reaction, the obtained solution is poured into a mold for molding. After the solvent evaporates, the polymer film is swelled in distilled water until the swelling balance is reached, and the polyurethaneurea hydrogel is obtained.

[0059] The characteristic of this embodiment is that the polyurethane prepolymer based on PCL 2k and PEG 4k as the mixed soft segment is synthesized first, and then the chain is extended with the small molecule chain extender et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

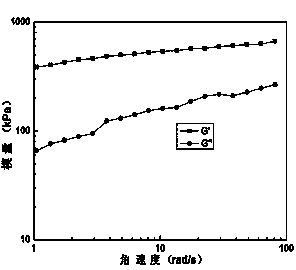

| Loss modulus | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com