Cured directly-coiled adhesive tape and preparation method thereof

A curing type, tape technology, applied in the direction of adhesive, adhesive type, film/sheet adhesive, etc., can solve the problems of strong irritating odor, air environment influence, time-consuming, etc., and achieve excellent bonding performance , reduce production costs, and shorten the aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of this curing type direct collection adhesive tape comprises the following steps:

[0025] Step 1): Weigh acrylic pressure-sensitive adhesive, modified epoxy resin curing agent, azobisisobutyronitrile and ethyl acetate respectively according to the above formula and put them into a reaction vessel and stir for 30 minutes to obtain a cured direct-acting adhesive. Adhesive for tape collection;

[0026] Step 2): Apply the sizing material obtained in the previous step evenly on the PET film;

[0027] Step 3): Baking and shaping in an oven at 110° C. for 2 to 5 minutes to obtain a cured direct-recovery adhesive tape.

[0028] The adhesive tape prepared according to the above method has special stickiness, can be rolled up directly, and does not need to be attached with a release material such as a release film, and the adhesive does not come off or peel off from the substrate.

Embodiment 1

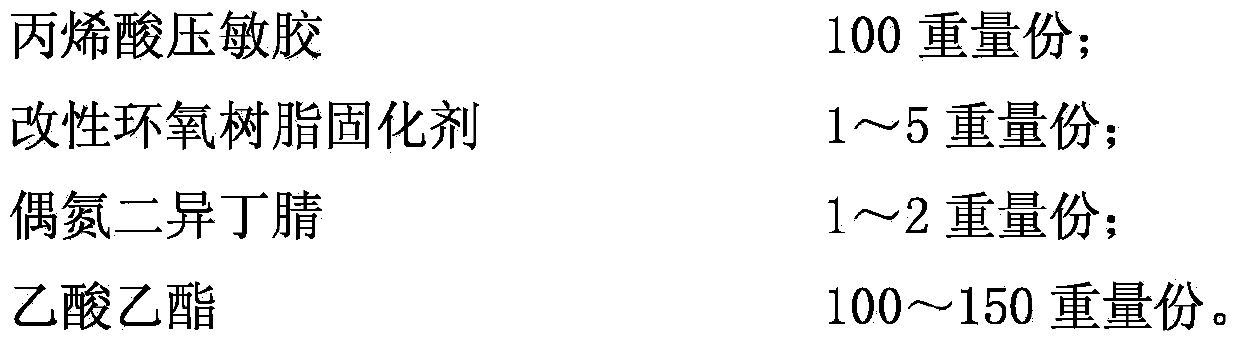

[0030] A curable direct-rewinding adhesive tape, which is made by coating glue on the surface of PET, drying it and winding it directly, and the formula of the glue is composed of the following materials:

[0031]

[0032] Curing time: 24h at room temperature, 5h at 60°C;

[0033] Tensile test: 25G / inch;

[0034] Glue binding force test: no degumming in the 100-grid test.

Embodiment 2

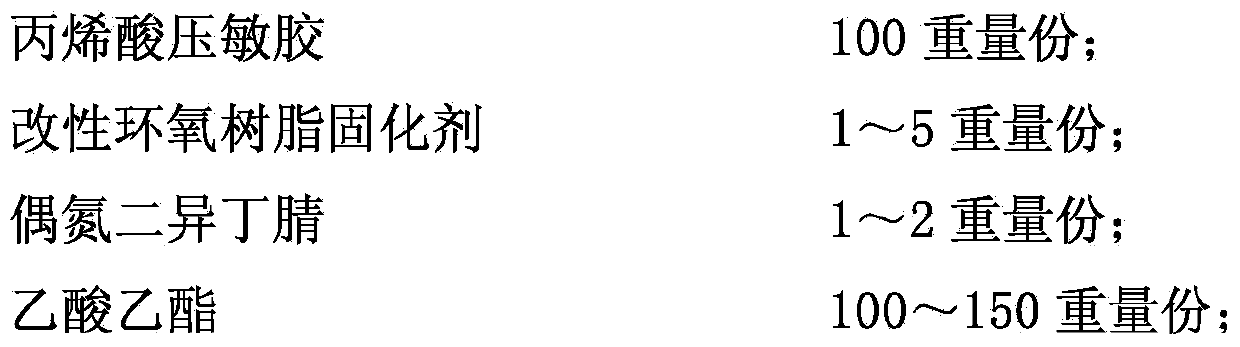

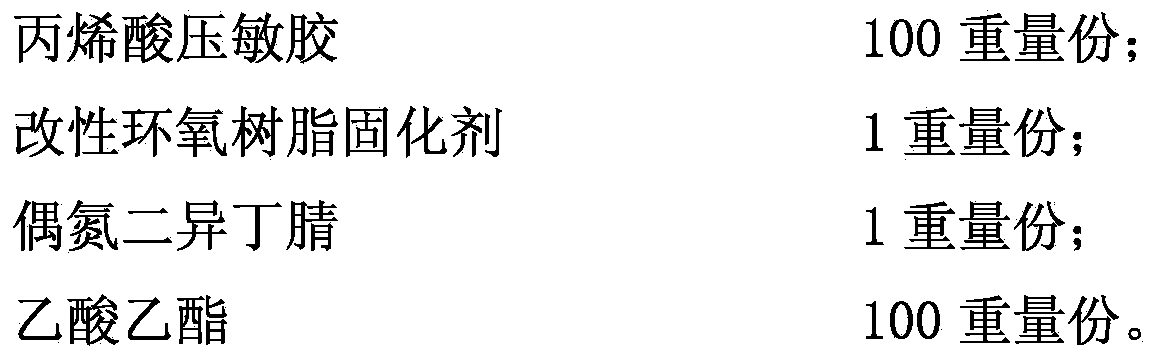

[0036] A curable direct-rewinding adhesive tape, which is made by coating glue on the surface of PET, drying it and winding it directly, and the formula of the glue is composed of the following materials:

[0037]

[0038] Curing time: 24h at room temperature, 2h at 60°C;

[0039] Tensile test: 5G / inch;

[0040] Glue binding force test: no degumming in the 100-grid test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com