Saccharification fermentation tank for production of novel rice-fragrant liquor

A saccharification fermentation, rice-flavored technology, applied in the field of saccharification fermentation tanks, can solve the problems of small volume of saccharification equipment and fermentation equipment, poor continuous production and automatic control, large production area, etc., and achieves good energy saving effect and sanitary grade. The effect of high, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

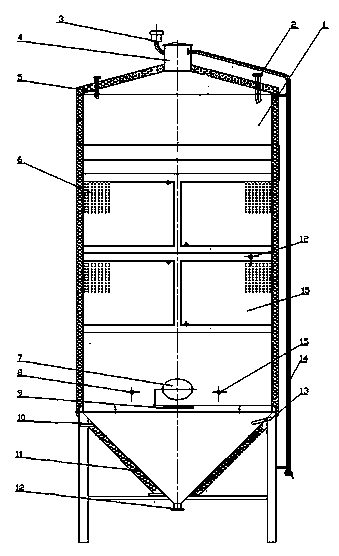

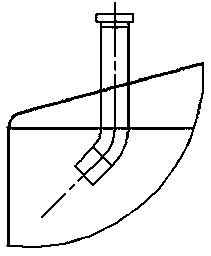

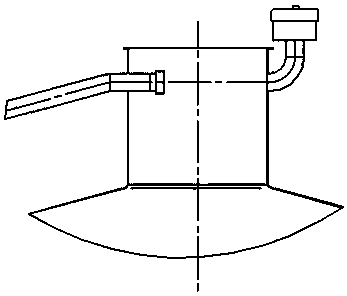

[0020] refer to figure 1 , a saccharification and fermentation tank for the production of a novel rice-flavored liquor of the present invention, comprising: a tank body 1, a feed inlet 2 arranged on the top of the tank body 1, a breathing valve 3, an upper mouth 4, a water inlet 5, a coating The Miller plate jacket 6 outside the tank, the lower mouth 7, the liquid level sensor 8, the handrail 9, the leg 10, the temperature sensor 13 at the bottom of the cone, the circulation pipe 14, the sampling port 15, and the bottom of the tank 1 outlet 12 at the bottom. Among them, the tank body 1 is a vertical cylindrical cone-top and cone-bottom normal-pressure container, including a cone top 17, a cylinder 18, and a cone bottom 19. The tank body 1 adopts a three-layer structure. The inner and outer layers are made of stainless steel, and the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com